Anticipating increases to production, the Wayne Farms, LLC, Pendergrass facility wanted an upgrade to its existing sequencing batch reactor (SBR), aerated lagoon and land application system (LAS) for wastewater treatment and activated sludge system. The single tank SBR and the LAS had reached capacity and could not handle significant additional flow. Accordingly, the facility applied for and was issued a National Pollutant Discharge Elimination System (NPDES) permit from the Georgia Environmental Protection Division (GaEPD) for direct discharge to Allen Creek, a tributary of the Middle Oconee River watershed.

To meet the NPDES discharge limits, the existing wastewater treatment plant needed to be upgraded to provide higher removal efficiency. Also, to manage potential water/drought in Georgia and reduce its water footprint, the facility requested the ability to recycle and reuse the treated effluent in non-food contact areas within the production plant.

Objectives for upgrade & design basis

The facility wanted the upgrade to:

- Use as much existing wastewater treatment equipment as possible because of its limited budget.

- Meet or exceed the NPDES discharge limits.

- Produce water of sufficient quality for reuse.

The facility’s wastewater treatment system was an activated sludge (AS) system that used a 1.6-million-gallon SBR and an aerated lagoon. Effluent from the production facility was screened and then underwent limited equalization (EQ). From the EQ, the wastewater flowed to a dissolved air flotation (DAF) unit and then to an aerated lagoon. From this lagoon, it traveled to the SBR and then to a series of lagoons for further treatment and storage.

Treated effluent would flow through the lagoons and be discharged through the LAS system. Waste activated sludge (WAS) was stored in the sludge lagoon.

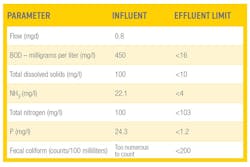

As part of the new design, the facility instituted a multiple-polymer system for the existing DAF. Table 1 shows the influent design parameters following the DAF.

Design alternative

To meet the three main objectives for the wastewater treatment system upgrade, water treatment professionals recommended a membrane bioreactor (MBR) system with denitrification, phosphorous removal and ultraviolet (UV) sanitation. Because MBRs do not rely on conventional settling and clarification, the concentration of biomass can be increased, decreasing the overall size of the system while increasing the amount of loading the system can handle. Ultrafilters (UF) would be used to separate the mixed liquor suspended solids (MLSS), which results in a high quality effluent as permeate (treated effluent).

With an MBR, the existing SBR tank could be converted to the bioreactor, and the existing blowers would be of sufficient size to maintain the biomass. The wastewater would be intercepted after the existing DAF, keeping the screen already in place, limited EQ and DAF in service.

Denitrification and phosphorus removal further added to the recyclability of the treated wastewater, meeting and exceeding the U.S. Department of Agriculture (USDA) Food Safety and Inspection Service (FSIS) requirements for reuse water in poultry plants.

Table 1. In fluent design parameters following the DAF unit

Design & construction

In the new system, wastewater, at a flow of 0.8 million gallons per day (mgd) from the existing DAF, is intercepted and rerouted. It then flows, using gravity, to a new reaction tank, which is located inside the new wastewater building, in which a coagulant is dosed to remove phosphorus. The tight total phosphorus limit is achieved by feeding an aluminum-based inorganic coagulant into the reactor tank following the DAF. This chemically precipitates the phosphates in one of two phosphate ponds before the water enters the activated sludge process. The former sludge holding pond was subdivided into two phosphorus settling ponds, one anoxic pond for denitrification and one WAS storage pond.

After flow through the phosphorous ponds and the anoxic pond, the water is pumped at a rate four times the influent flow rate to the bioreactor (converted SBR tank). The mixed liquor from the bioreactor is then transported to the new wastewater building that houses the UF membrane skids.

The UF system, made of two skids with two units each, includes 10-inch diameter by 4-meter tubular UF membranes with 8-millimeter tubes. Each unit contains six modules, and each module has 575.12 square feet.

Reject (concentrate) from the membranes flows back to the anoxic pond as return activated sludge (RAS). Permeate flows from the membranes at the system influent rate, through a UV system for disinfection, then into a stainless steel reuse storage tank. Overflow from the reuse storage tank moves through the flume/monitoring station, down the cascade aeration and to Allen Creek.

System startup

A system startup was attempted in July 2013. Several issues immediately became apparent:

- Mineral scale deposition developed because of high hardness from the production well water.

- The membranes and screens plugged and fouled due to the vegetative growth (leaves and grass) in the anoxic basin.

- The membranes and screens plugged from and were fouled by feathers because of periodic bypasses from the existing DAF.

- Excessive fats, oils and grease and phosphorus increased because of partial treatment during DAF surges.

- Significant debris inside the existing SBR tank caused clogging of the inline screens/strainers on the membrane feed pumps.

- Some pipes broke on the membrane skids.

- The tank fitting for the membrane feed pumps was too small. This was an existing fitting that was shown incorrectly on the older system drawings and could not be visually verified because it was below grade.

System operation

These issues were systematically addressed, and the treatment system was fully operational in August 2013. Several long-term operational considerations were determined:

- A balance between membrane flushes and cleaning was decided. Cleaning membranes is important, and the cleaning solution, its temperature and the frequency of cleaning are somewhat unique to a system.

- The high hardness present in the well water that supplies the facility required the use of a more intensive acid cleaning regime.

- The membranes had considerably better performance with established biomass than with young sludge.

- The facility had previously used a limited amount of DAF effluent for reuse. With the high effluent quality of the new system, it is now reusing up to 120,000 gallons per day for pump seal flush, screen flush and other tasks.

- This facility’s specific wastewater characteristics required additional membranes in February 2014. The sizes of the pressurization pumps’ impellers were increased to accommodate the additional membranes, and more structural supports were added to the membrane skids to eliminate pipe breakages. Additionally, UF skids were originally installed with five modules per unit. Two additional membrane modules were installed on each skid for a total of six modules per unit.

Conclusion

Treated wastewater from the MBR system consistently meets or exceeds the NPDES discharge limits. It also exceeds the USDA FSIS requirements for reuse water at poultry plants. The high-quality effluent from the facility’s permitted discharge has improved the overall water quality in Allen Creek.

To ensure that the system operates well, the facility added qualified personnel on all shifts, instituted continuous training for wastewater operations personnel and performed significant in-house process testing. The MBR system won the 2015 Georgia Association of Water Professionals Industrial Direct Discharge – Biological Treatment System Plant of the Year.

Jim L. Lewis is the president of Complete Water Services, LLC, a company that provides water and wastewater treatment services for the Americas, including design/build for industrial water and wastewater systems, contract operations and consulting services. He has more than 40 years of experience in the water treatment industry across a range of water and wastewater specialties including plant operations, industrial services management and process design. He may be reached at 678-355-9270.

Author’s note: The author thanks Brian A. Rindt, P.E., of Rindt-McDuff Associates Inc. and Karen J. Niebuhr, P.E., of Complete Water Services LLC for their assistance with this project and article.