New Hybrid Cooler Technology Saves Water, Reduces Energy Use

By Ben Cohen

Several global trends are contributing to the desire for cooling system solutions that can save energy while also saving water. Heavy flooding in some regions, higher drought levels in other regions, and extreme temperatures and weather events have been driving the need for new solutions. In addition, the population is increasing in these regions, and emerging markets continue to see migration from rural areas to cities. As new trends have emerged, many customers, especially in California and the western United States, have been looking for solutions that save water while still maintaining the benefits of evaporative cooling equipment.

Since energy and water production are interrelated, it is important to select equipment that appropriately balances energy and water usage. Although air-cooled and water-cooled systems each have their tradeoffs, engineers often design water-cooled systems for lower energy consumption and a smaller footprint than air-cooled equipment. Water-cooled systems continue to free power grids from excessive strain while reducing water usage at power plants. However, some applications can benefit from additional flexibility to balance energy and water savings.

Now, a new hybrid cooler technology offers energy efficiency in addition to providing water savings. A combination of a high dry switchpoint and redundancy features contributes to reliable year-round operation. In addition, the new equipment has a crossflow design that reduces maintenance and operating costs while providing layout flexibility.

Comparing water and energy use in air-cooled and water-cooled systems

There are two types of cooling systems, air-cooled and water-cooled, and the difference between these two systems is related to design temperatures.

Air-cooled systems are designed based on the ambient dry bulb temperature, while water-cooled systems are designed based on the ambient wet bulb temperature. For example, the design wet bulb temperature in Baltimore, MD, is typically 78℉, which is significantly lower than the design dry bulb temperature of 95℉. Since water-cooled systems are designed around this lower temperature, water-cooled equipment has a smaller footprint and uses significantly less energy than air-cooled systems.

Energy savings and footprint reduction vary due to several factors, including the amount of heat to be rejected, geography, and jobsite conditions. Therefore, it is important to understand application needs and jobsite constraints in order to select the best system type for your application.

New hybrid cooler technology optimizes water and energy savings

For those applications that can benefit from more closely controlling resource utilization, owners look for the optimal balance between energy use and water consumption, especially if access to water is limited. A new hybrid heat transfer technology has been developed for applications where water is scarce or expensive. Applications that may benefit from hybrid technology include data centers, manufacturing, industrial, power and process, and HVAC applications.

One example of this hybrid technology is the HXV Hybrid Cooler, which offers both energy efficiency and water savings. This technology uses different operation modes to reduce water and energy consumption. The option to use dry operation and the equipment’s crossflow design results in up to 25% maintenance savings compared to traditional evaporative fluid coolers. A key part of the general maintenance cost savings is the 70% chemical savings, since the equipment can operate dry throughout much of the year.

Delivering energy-efficient cooling while maximizing water savings, this hybrid cooler saves up to 70% of water compared to other evaporative cooling equipment, with a higher dry switchpoint. It also saves up to 60% more energy than air-cooled equipment.

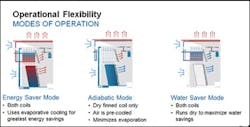

The unique design includes two coil sections, the prime surface coil section and the finned coil section. These heat transfer sections operate in three different modes: energy saver (combined wet/dry); adiabatic; and water saver (dry). This means that users can balance water and energy savings based on their specific application needs.

The energy saver mode offers the most efficient heat transfer method and flow control. Initial cooling occurs in the finned coil as air passing over the finned coil pre-cools the internal fluid. As spray water is distributed over the prime surface coil, primary evaporative cooling occurs. Using both sensible and evaporative heat transfer, the combined mode results in significant water savings compared to conventional evaporative units, even at peak design conditions. (The sensible cooling of air is the process in which only the sensible heat of the air is removed so as to reduce its temperature, and there is no change in the air’s moisture content).[1] Energy saver mode always saves around 25% water because the dry finned coil is always sensibly cooling approximately around 25% of the heat load.

Adiabatic mode occurs when the process fluid flows through the finned coil only and completely bypasses the evaporative prime surface coil. Water continues to evaporate over the fill, pre-cooling the incoming outside air before it reaches the finned coil, greatly increasing the rate of sensible heat transfer. With reduced water consumption while maintaining the low fluid design temperatures required to maximize system efficiency, adiabatic mode saves up to 75% of water.

Operating in adiabatic mode has another benefit – it greatly reduces visible plume that occurs when the air is fully saturated, especially in colder and damper conditions. Many operators want to reduce or eliminate the plume for aesthetic reasons.

With water saver mode, both coils are used to maximize the heat transfer surface area. The spray water pump is turned off and no water is consumed. The fluid to be cooled passes from the finned coil into the prime surface coil, maximizing the heat transfer surface available. In dry mode, plume is eliminated. The unit runs dry to maximize water savings and can achieve even higher dry switch points when running at partial load. Water saver mode saves 100% of water use, as all heat is rejected sensibly. Figure 1 illustrates the operational flexibility offered by the three available operation modes.

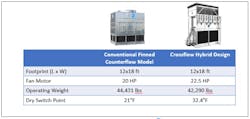

Figure 2 shows an example of how the hybrid technology design can save water compared to traditional finned coil products. The hybrid technology has a lower operating weight than the traditional model but an 11.4℉ higher dry switch point. The higher dry switch point minimizes both water and chemical use.

Reduced maintenance costs and highest uptime

The new hybrid technology also has reduced maintenance costs compared to other hybrid products. The crossflow design provides easy and fast access with ample room to access key components, especially the coil, motors, fill and spray branches, and water collection basin. The spray distribution system and coil sections are highly visible and can be quickly inspected during operation. Additionally, the combined flow design allows for evaporation in two areas:

· Prime surface coil - water flows in the same path as the air along with evaporation, fully wetting the tubes and preventing unnecessary scale buildup

· Fill section – 70% of the evaporation occurs in this section

The fully wetted tubes and reduced evaporation over the coil section along with the benefits listed above ensure higher system uptime than other hybrid evaporative technologies.

Figure 3 illustrates how the combined flow design fully wets the coil tubes when compared to conventional counterflow designs that can leave dry spots and result in scale buildup.

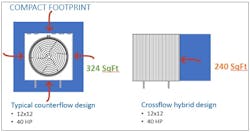

Figure 4 shows how the hybrid technology offers a compact footprint that can be a factor in achieving layout flexibility.

Both units are 12-feet x 12-feet models, with a total fan HP of 40. The typical counterflow design requires clearance on all four sides due to the induced draft design. The new hybrid design has a single side air inlet as well as 30% of the air coming in from above the wet coil, which means only one side requires clearance and it is reduced for 70% of the airflow. The result is an overall footprint for the typical counterflow design of 18-feet x 18-feet, or 324 square feet. The overall footprint of the hybrid design is 12-feet x 20-feet, or 240 square feet, which is 84 square feet less, a 26% reduction in footprint.

Water consumption in cooling systems is in some ways industry specific. For example, data centers use massive amounts of energy and often select evaporative cooling because they want to reduce their energy costs. At the same time, they also require redundancy in the event of water loss or having to accommodate water restrictions.

The HXV Hybrid Cooler has recently been selected for a large liquified natural gas facility and its process cooling loop. The main drivers for use of the HXV on this project were plume abatement and water savings. Additionally, due to the remote location of this facility, the HXV Hybrid Cooler’s modular design allows for minimized site labor and faster install time compared to field-erected equipment. This ultimately results in lower contractor risk and on-time completion.

Demand growing for evaporative cooling equipment with increased operating flexibility

Traditional evaporative heat rejection remains the go-to solution for low system energy use and reduced footprint. However, as demand grows for evaporative cooling equipment with additional operating flexibility, new hybrid technologies offer innovative solutions that balance energy and water savings based on specific application needs. Today’s customers must consider geography, application, jurisdiction, and regulations as they select the right cooling system for their projects.

About the Author

Ben Cohen is manager of product marketing, North America, for Baltimore Aircoil Company.

References

[1] Psychrometric Processes: Sensible Cooling & Sensible Heating of Air, Bright Hub Engineering, https://www.brighthubengineering.com/hvac/41436-psychrometric-processes-sensible-cooling-and-sensible-heating-of-air/, retrieved 8/1/19.