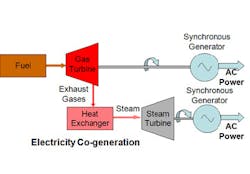

Power plantsuse high purity water to drive steam turbines. Cogeneration plants are highly efficient, using both exhaust turbines and high pressure steam turbines.

In the 1960s, boilers operated at 450°C (840°F) and 4MPa (40 atmospheres). Today's leading edge boilers operate at 620°C (1150°F) and 30MPa (300To keep power efficiency high, maximize uptime and minimize turbine maintenance, boiler makeup water must be ultrapure (17+ Megohm.cm) and have very little silica (SiO2). Silica levels required are in the range of 5-20 ppb, depending on the boiler pressure. Under the boiler/turbine conditions, dissolved silica will form a glass on surfaces like the turbine blades.

Mixed Bed DI technology is a batch process, and requires duplex towers. There can be a spike in silica whenever the MB’s are swapped. Electrodeionization (EDI) does not have this problem.

Today, state of the art boiler water makeup uses RO-GTM-EDI to achieve continuous low levels of silica feeding the boiler system. 1-5 ppb silica is achievable with the proper components and system design.