Having been directly involved in the "greening" of the professional cleaning industry for more than 20 years and now working to make it more sustainable as well, if there is one thing I have learned over the years it is that "green" and sustainability are not static issues. Instead, we should view "green," green cleaning and sustainability as always evolving and growing, with the ultimate goal of helping facilities operate in a healthier, more resource responsible manner.

An example of this evolution, which will impact commercial building owners, managers and the entire water technology industry, occurred late last year. In November 2013, at the Greenbuild International Conference and Expo in Philadelphia, the U.S. Green Building Council (USGBC) officially launched LEED v4. Although it builds on the previous LEED standards, one of the fundamental changes in this new version of the LEED rating system is an emphasis on water-related issues. In particular, LEED-EB (existing buildings) is designed to help improve efficiencies in older buildings, especially when it comes to energy and, of course, water.

Why the greater emphasis on water? In part, it is the result of advances in technology that help facilities use water much more efficiently, many of which have been introduced in just the past few years. Possibly even more important, however, is the fact that the USGBC as well as most green and sustainability experts foresee water concerns becoming a major issue in the 21st century. Not only that, but these concerns are likely to become more pressing sooner than anticipated. Taking steps now may help avoid, prevent or minimize water emergencies.

The LEED specifics

Before we go further, some terminology clarifications are in order. For a facility to receive LEED credits it must meet specific criteria as to water efficiency and now water conservation. What’s the difference? Water conservation references short-term measures taken to reduce water consumption during an emergency such as a drought. Once the emergency has passed, water consumption typically returns to normal.

Efficiency, on the other hand, is long term. Whether in a drought condition or, for that matter, during an unusually wet period, the steps taken to reduce water consumption remain in effect.

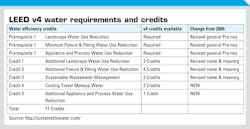

With that clarification, the following are the prerequisites for LEED v4 that commercial building owners and managers as well as those in the water technology industry should be aware of:

- Outdoor water use reduction: Using the EPA’s WaterSense Water Budget Tool, existing facilities must reduce water used for landscaping and outdoor vegetation by 30 percent.

- Indoor water use reduction: Certain fixtures and fittings must bear the WaterSense Label. In addition, cooling tower requirements from ASHRAE 189 have been adopted. Further water reduction requirements have been added for retail, hospitality and healthcare facilities specifically. Note: Formerly these prerequisites were referred to as “Water Use Reduction” and “Water Efficient Landscaping.”

- Building-level metering: A new requirement, each project must now be capable of measuring whole-building water use.

Building owners can earn water-related credits once these prerequisites have been implemented. Among these credits include the following, which can vary depending on the type of facility (office, hospital, retail, etc.) or how it is used:

- Outdoor water use reduction: One credit is earned if outdoor water use is reduced by 50 percent or more (compared to previous consumption if an existing building), again using the EPA’s WaterSense Water Budget Tool.

- Indoor water use reduction: One credit is earned for adding water-saving appliances and complying with process water requirements. Process refers to water used for industrial processes, manufacturing or building systems, such as cooling towers, boilers and chillers.

- Cooling tower water use: This new credit is designed to encourage building project designers to analyze water sources and maximize water cycles.

- Water metering: Another new credit, this rewards facilities for expanding water metering and submetering to at least two water "end uses."

The ultimate goals of v4’s water efficiency prerequisites and credits is to have a much more complete picture of how water is used in a facility. Additionally, with this knowledge available, building managers are encouraged to identify and facilitate steps where water can be used more efficiently and waste eliminated.

Opportunities for water technology dealers

While there is invariably some resistance to change, it can also bring about many opportunities. For astute water technology dealers, just having an extensive and thorough understanding of v4’s water requirements and credits will help turn them into experts. Many end customers, such as building owners, will likely turn to dealers for guidance regarding how they can earn LEED credits based on the new version, equating to more clients for educated dealers.

However, dealers can take more specific steps as well. For instance, one of the most significant ways facilities can reduce water consumption — and one that is written right in to the standards — involves reducing water used for cooling. With a 10-ton cooling chiller, which is considered a “typical” cooling tower found on many commercial facilities, water is pumped to the top of the system and is then either sprayed or allowed to drip down the unit. The process is referred to as "blowdown" and is the focus of LEED v4’s cooling tower credit. The blowdown cools air that is then pumped in to the facility; however, the process causes water to evaporate at a loss of about three gallons of water per minute.

It is believed that thousands of gallons of water can be saved by using new and existing technologies and methods that increase water recirculation cycles. Further, this can be accomplished with little impact to building user comfort or the equipment used to cool the facility. It also serves as an opportunity for water technology dealers who are aware of this issue and how it can be addressed to work with their clients, helping them attain LEED credits or meet LEED water efficiency guidelines.