Landia supplies mixers for poultry plant effluent; Fluence wins contracts; Legionella conference May 9-11

Landia provides mixing and aeration solution for poultry plant effluent

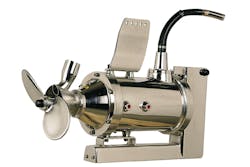

Landia won a new order to supply stainless steel mixers to a large poultry plant in West Midlands, England, where previous equipment had failed due to corrosion. For the customer, a major supplier to supermarkets, the installation of the 4 kW, 1,500 rpm mixers will also introduce much-needed air into the process to eliminate odors. Serving 100 m3 balance tanks, the Landia PODBR-I submersible mixers/aerators will simultaneously mix and aerate the acidic, screened poultry plant effluent and prevent septicity from occurring.

"For smaller tanks where a little oxygen is required, together with thorough mixing, the Landia direct-drive mixer/aerator provides a one-stop solution, because it performs both jobs in a single operation," said Landia’s Paul Davies. "For this project, our fully-cast stainless steel units were specified, although we also offer a cast iron variant for less aggressive effluents."

Fluence wins $8M in new contracts since January 2018

Fluence Corporation Limited has delivered $8 million in new contract wins since January 1, 2018, including three NIROBOX orders. The new contracts include:

- Fluence Italy won a repeat customer in the agro-industry to design and implement an upgrade and expansion of their aerobic treatment line. Fluence’s technologies has helped the customer reduce costs and expand capacities.

- Fluence Argentina will design and deliver a reverse osmosis (RO) system as an expansion of 3,000 m3/day to an existing installation, with added filtration and treatment systems to aid in arsenic removal, to one of the largest municipal utilities in Buenos Aires.

- Fluence Brazil will design and deliver a turnkey wastewater treatment plant for industrial process reuse to Brazil’s largest national pharmaceutical group. This group selected Fluence to provide this solution, utilizing RO, ultra-filtration and MBBR, among other technologies, to supply 7.5 m3/hour of process water to its operation in Sao Paulo.

- Fluence USA won another repeat customer, a renowned food and beverage industry customer, to upgrade its aeration process for an additional two lagoons, following last year’s order of Fluence’s Tornado Surface Aspirating aerator/mixer. The equipment and service provided by Fluence enables this client to comply with local regulations in an efficient and cost-effective manner.

Legionella conference May 9-11 in Baltimore

This practical conference, "Managing Legionella and Other Pathogens in Building Water Systems," focuses on controlling risks from exposure to Legionella in water plumbing, cooling towers and pools and spas. Many microorganisms regrow post-drinking water treatment and colonize distribution, plumbing and cooling water systems.

Outbreaks involving thousands of cases of Legionella-associated respiratory disease and at least hundreds of deaths have been reported in the U.S. and Europe since the first identified legionellosis outbreak in Philadelphia in 1976. Legionella pneumophila, in particular, is a significant public health concern.

Since the implementation of the Safe Drinking Water Act regulations in about 1980, there has been a general decline in reported traditional waterborne disease outbreaks, but an increase of those associated with water distribution rather than source water treatment.

Periodic reports of Legionella disease outbreaks associated with hospitals and cooling water systems attract national publicity, but the community of water suppliers, building facilities, state regulators, health care and plumbing officials are still lacking adequate information and advice on the physical plumbing water conditions, microbial monitoring and detection, and prevention and mitigation opportunities that can reduce risks to the public.

For information about the conference and registration details, go to legionella2018.org or contact Joseph Cotruvo at [email protected] or Dave Purkiss at [email protected].