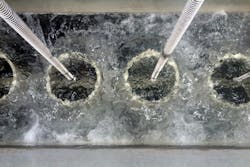

World Water Works DAF system at casting facility; Eaton self-cleaning strainer at iron and steel facility

World Water Works DAF system treats water at casting facility

World Water Works installed its dissolved air flotation (DAF) system at an aluminum casting facility of a producer of semi-fabricated aluminum products. The 1,500 gpm system using 25 horsepower (hp) is consistently achieving greater than 95 percent removal efficiencies, and it has improved production yields of the aluminum casting process.

Courtesy of World Water Works

The aluminum casting facility uses a closed-loop contact water system that supplies water to multiple DC casting pits. Its existing induced air flotation (IAF) system was used for the reduction of TSS, NTU and oil and grease, followed by a cooling tower. The treated and cooled water was then reused in the caster as contact water. The IAF had a removal efficiency of approximately 40 percent, required regular maintenance attention, operated at 125 hp and used an excessive amount of chemistry, resulting in high operating costs. In the event that the facility experiences an oil spill, oil enters the water system. When this occurred, the IAF was unable to handle the increased loading, typically forcing the facility to shut down for days at a time. Additionally, the downstream cooling tower fed by the IAF required large amounts of biocides in order to maintain effectiveness.

Since the installation of World Water Works’ DAF system, the quality of the caster contact water has improved, while using one-fifth of the horsepower as the previous IAF system and reducing the chemical usage. The facility now operates with minimal operator interface and without significant maintenance attention.

Eaton self-cleaning strainer filters water at iron and steel facility

Eaton’s automatic self-cleaning strainer with a 3.9 millimeter (5/32″) perforated convoluted element was selected for the recycling water intake piping system at XINXING, an iron and steel manufacturer in China, to solve filtration issues with water containing iron fragments, sand and minerals particles. With the new strainer, 98 percent of the greater than 4 mm particles are removed from the water, reducing the potential for damage to upstream components.

With flow rates of up to 35,000 gpm, a broad selection of screen options, automatic backwashing and exclusive IdL seal for leak-free service, this strainer is designed for continuous, uninterrupted removal of entrained solids from liquids in pipeline systems. Courtesy of Eaton

In the facility, water is applied to cool the iron-making furnace equipment, and then the water is gravity fed upstream to a collection sink basin before being pumped onward at a flow rate of 13,210 gpm to a heat exchange recycle system. However, the water that is collected to be reused needs to be filtered to remove particles before it can be pumped onward. Any contamination greater than 4 mm in size causes problems within the heat exchanger, as it contains many sensitive components such as flow rate valves. When these valves were being fed with "dirty" water, they degraded rapidly in terms of performance and even failed. Maintenance was an ongoing issue, and biweekly cleaning was required to clean out the contamination. Typically, these maintenance periods lasted around one week and entailed a full system shutdown thus incurring significant production losses.

The solution: One 30″ strainer replaced three sets of previously installed filters, saving space on the factory floor. The new system cut down on unplanned interruptions to the local heating system and reduced water consumption in the plant by 20 percent. Plant maintenance shutdown was minimized to ensure that production could continue uninterrupted. The manufacturer now only conducts maintenance once a year, saving on both labor and spare parts costs that need to be replaced using the previous solution.