U.S. industrial plants spending $18B per year for flow control, treatment, finds study

March 13, 2015 -- According to the McIlvaine Company, industry in the United States is expanding due to the rising economy, and the heavy industrial sector is showing high growth due to the low cost of energy. Further, annual purchases of liquid (including water and process fluids) flow control and treatment products and services are expected to exceed $18 billion per year.

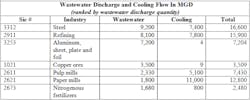

McIlvaine's "Industrial Water: Plants and Projects" report tracks various activities at more than 20,000 plants, which are segmented into 100 industry categories. The findings also indicate that a few industries discharge more than 2,000 million gallons per day (MGD) of wastewater.

The intake water quantity has been found to be slightly larger than the water discharged. The largest investment in flow and treatment is due to the recirculation of liquids for process and cooling purposes. This can amount to more than 5,000 MGD in a number of industries.

There are more than 1,000 large industrial boilers with substantial treatment systems to purify the water needed for steam generation. Most of these have closed loops with condensate return. A number of smaller industrial boilers also utilize water for steam production but recirculate less water and, therefore, need less purification to avoid concentrating contaminants.

Plant expansions requiring liquid flow and treatment equipment are chronicled with continuing updates.

See also:

"Analysis shows billions predicted to be spent for U.S. water infrastructure upgrades"

"Oil and gas industry to spend over $10B for valves in 2015, finds study"

###