Optimizing Pretreatment Key to Boiler Feedwater Quality

Maintaining boiler feedwater (BFW) quality is essential to the efficient and reliable operation of a boiler system. The old axiom of "garbage in – garbage out" has great significance in the pretreatment process. In many cases, having the right monitoring equipment is key to system performance.

If the pretreatment system is performing properly, the internal chemical treatment program is pretty straightforward and should produce clean and efficient boilers. Frequently, feedwater quality problems are caused by operational practices. This is usually not a reflection of operating personnel capability, but a result of insufficient "tools" for equipment monitoring and control.

Many factors (economic and environmental) have caused even low pressure boilers to now use an ultrapure pretreatment process with reverse osmosis (RO), and demineralizers. Most high pressure boilers (>1000 PSIG) have a condensate polishing system to minimize problems associated with corrosion products (typically, iron and copper), and various process contaminants. Some process contaminants can cause severe boiler water chemistry upsets, and problems such as corrosion, foaming, and carryover to steam turbines.

The primary function of clarifiers is to remove suspended solids such as silt, or, in the case of hard waters, for softening. However, they can be very effective in removing organics, iron, manganese, and other undesirable materials. Proper and consistent coagulant dosage is essential to maintaining clarifier performance, and can have major effects on downstream equipment.

Monitoring, Control

Jar tests and turbidimeters have been the traditional instruments for monitoring and controlling clarification processes. In recent years, the streaming current monitor (SCM), particle counters, and particle monitors have replaced these methods. These instruments provide continuous, precise, and sensitive measurement, and true "process optimization" capability.

Periodic jar tests give a ball park idea of what coagulant dosages should be, but are somewhat subjective. The SCM provides continuous monitoring and automatic control. Turbidimeters have also been used to monitor filter performance, but lack the sensitivity of particle counters/monitors. Silt density index (SDI) has been the standard test to predict membrane fouling. However, it is not a continuous measurement, and usually is not helpful in troubleshooting and improving upstream processes.

Case History

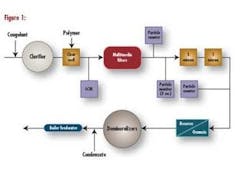

A large, fossil fueled electric generating plant installed a reverse osmosis system to reduce demineralizer loading and minimize regenerations. The BFW treatment system is shown in Figure 1. Water source is a river with an intermediate settling basin that minimizes large turbidity swings to the treatment process. Primary coagulant was alum, but was later changed to a polymer/ inorganic blend. Turbidimeters are used to monitor clarifier and filter effluents. SDI tests were performed for a time after the RO installation, but were eventually discontinued. Feedwater pressure buildup and frequent membrane cleaning has been a persistent problem since commissioning several years ago.

The Program

Particle counters/monitors were installed as shown to get baseline equipment performance. The objective was to improve removal of sub-micron particulate in the multimedia filters by feeding a small amount of polymer filter aid. Although the counters/monitors used do not detect particles in the sub-micron range, it is well known that colloids are absorbed on filter media that is properly conditioned with a filter aid. The instruments provided an excellent correlation as proven by the end results. An SCM was used to optimize polymer feed to ensure that the absolute minimum was being used, and would not carry through to the RO. Polymer fouling can be a problem in itself if overfed.

Results

Results are shown in Figure 2. Without polymer feed, particle counts in the multimedia effluent were over 200/ml. With polymer, counts dropped to less than 50/ml, with many periods less than 5/ml. Polymer dose was less than 0.5 ppm. An immediate improvement was seen in the RO operation. Cleaning frequency went from once per week to once per month. Feedwater pressure buildup was less than 2.0 PSIG after 30 days.

Currently, the plant is monitoring three of the multimedia filters with particle monitors, and the combined effluent with a particle counter. Polymer addition is being automatically controlled with a streaming current monitor using filter influent flow and streaming current in a combined algorithm.

Conclusion

The return on investment (ROI) of using sensitive and reliable control instrumentation in a BFW pretreatment system can be substantial. Savings in chemicals, filter replacements, membrane cleaning/replacement, and demineralizer efficiency can be documented fairly accurately. The major benefit is always boiler efficiency and reliability.