Ion Exchange for High Purity Water Using Advanced EDI

By Erik Hanson and Tom Kosir

Located in a wooded area along a peaceful river in the Upper Midwest is a coal-fired power plant that has been providing base load power to its regional customers for decades. Like most coal-fired power plants of its generation, it’s facility is old but its workforce is experienced and flexible. This plant has methodically been upgrading critical systems over its lifetime, and it recently had the opportunity to upgrade its water system.

During this upgrade, the plant faced a decision that many power plants face: rebuild the system with the same ion exchange technologies that have served it well for decades, or upgrade the technologies to make use of electrodeionization, adding significant potential benefits to the plant but also installing technology that is new to the plant personnel.

Traditional ion exchange technology has a long history of high-quality water output and reliable performance. Many power plants have depended on it for so long that they have come to accept its downsides, such as high chemical usage, larger plant footprint, and a high level of operator interaction, as facts of life. Electrodeionization (EDI) was introduced as an alternative almost 30 years ago, as an innovative way to dramatically reduce chemical usage, and minimize footprint and operator interaction. But the early days of EDI did not see the sweeping change from traditional ion exchange that many water professionals anticipated.

EDI works by using the exact same principles of ion exchange as traditional methods. Resin beads exchange salts in cation and anion form for H+ and OH- in both technologies. The difference lies in the regeneration of the resin. EDI regenerates the resin beads continuously using electricity. This provides the dual benefits of eliminating acid and caustic chemical usage for regeneration, and eliminating the batch process that requires traditional ion exchange to be off-line intermittently while being regenerated. Additionally, because the resin beads never need to be backwashed or separated in a fluidized bed, they do not need to be installed in the large pressurized tanks associated with traditional deionization. And because EDIs require less resin for a given flow, the equipment size is smaller. These benefits result in significant plant footprint savings.

All those benefits led water professionals to expect the entire industry to shift to EDI quickly. But in the very early days of this technology, prior to 2000, there was also a drawback. The EDI stacks had an inlet calcium and magnesium limitation of around 0.5 mg/L hardness as CaCO3. Pushing the limits beyond 0.5 mg/L resulted in scale forming in the stacks, and operational issues. Additionally, for plants to stay within this operating limit for hardness, a two-pass reverse osmosis system or a softener was often required, negatively impacting the size of the capital investment and the payback of the overall upgrade. Some of the earliest installations developed problems that scared off other plants and set EDI technology back in terms of market acceptance by several years. Systems with overly aggressive designs around hardness levels contributed to most of these early plant problems.

Fortunately, technical advances in EDI stacks began to address this hardness issue in the mid-2000s. Two critical innovations took place that grew the application of EDI into one of the leading technologies used in the production of ultrapure water. These advances were the introduction of counter-current flow through the stack, and a concentrate spacer design that managed both fluid dynamics and scaling potential within the stack.

The concept of co-current versus counter-current flow through ion exchange resin existed in traditional ion exchange well before it was successfully translated to EDI. However, its effect on resin performance is different. The principle is based on the zone of the EDI stack or the resin column in the case of traditional ion exchange. In both cases, ions enter a zone of resin, and the strongest concentration of the divalent ions is exactly at the entrance point. At that point, they begin getting exchanged for H+ ions, and the divalent concentration of the water gets smaller and smaller as it flows through the resin bed. In a co-current design in traditional ion exchange, the regeneration is done in the same flow direction as the normal flow rate, resulting in the regeneration seeing its greatest challenge right at the beginning of the resin. Regenerating the resin further into the column then requires more chemicals.

Counter-current flow reverses the flow through the resin during regeneration. The resin bed still gets the highest concentration of divalent ions at the entry point to the resin beads during normal flow. However, the regeneration flow starts at the opposite end of the resin bed. In this scenario, the regeneration works first on the least exhausted resin beads, and regenerates the highest concentration of divalent ions last instead of first. This regeneration method is two to four times more efficient than the co-current method, and in traditional ion exchange, it helps save chemicals with more efficient regeneration. In EDI, counter-current flow looks similar from the perspective of the flow path. Using this flow configuration in combination with once-through flow in the stack dramatically reduces the rate of hardness scaling while keeping the performance at its normal high level. This is one of the two technology leaps taken in EDI that dramatically increased hardness tolerance of the EDI stacks.

The second significant improvement to EDI comes from innovation in the concentrate spacer design. Early EDI stacks (like GE’s E-Cell™ stack shown in Figure 1) utilized ion exchange resin in the dilute flow path of the stack (the path taken by the feed flow to the EDI), getting polished as it progresses through the stack. The ions being removed from the dilute streams were carried out of the stack in the concentrate stream, which was isolated from the dilute streams by charged membranes (cationic and anionic). This concentrate stream originally contained no resin, so for effective regeneration, the conductivity of the water in the concentrate spacer had to be carefully maintained.

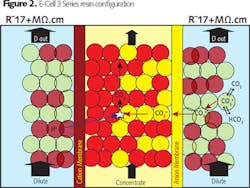

Innovations in the industry in the early 2000s found that by filling the concentrate spacer with resin, quality, efficiency, and hardness tolerance were dramatically improved. Resin beads in the concentrate spacer help conduct the ions across the stack and out of the EDI system, allowing the system to run without such careful attention being paid to internal stack conductivities. This improvement also made the stack more efficient in terms of electrical consumption because the ions move across the resin with less potential energy than across water in the same space. Finally, through significant experimentation at GE Water & Process Technologies, it was discovered that hardness tolerance was improved by layering the cation resin near the membrane surface, and mixing cation and anion resin through the rest of the concentrate chamber. Figure 2 shows a diagram of the E-Cell 3 Series resin configuration.

These two innovations have been adapted by all of GE’s E-Cell EDI products since the mid-2000s, and they have greatly increased the reliability and adaption of EDI technology around the world.

Today, because of these two advances, EDI has become commonplace in any application requiring ultrapure water, whether it is a microelectronics plant producing the latest semiconductors for computers and phones, or a coal fired-power plant upgrading to the best available technology for the water system.

The coal-fired power plant that was introduced at the beginning of this article was faced with the same choice as many other power plants before it. Fortunately, they benefited from the past 15 years of innovations in EDI technology and could make their choice without concerns of hardness or other failures that happened in the 1990s. This power plant has now been operating E-Cell EDI technology as the ion exchange step following several single-pass GE Reverse Osmosis systems for nearly five years. The economics of its decision have paid off in all categories. Chemical consumption for the EDI system is close to zero. It doesn’t use acid or caustic in regeneration. Its operation is continuous. It doesn’t require redundancy or back-up as would be required for traditional ion exchange batch mode operation. The water quality is consistently high, easily exceeding the specifications of the power plant. And its experienced operations staff spend their time keeping the power plant running while an advanced SCADA system monitors their trouble-free water system.

About the Authors:

Erik Hanson is the director of global product management for separations and systems at GE Water & Process Technologies located in Minnetonka, Minn. He has over 20 years of experience in industrial and municipal water treatment and is a graduate in Electrical Engineering from North Dakota State University in Fargo, N.D.

Tom Kosir is the global product line director for E-Cell and PRO E-Cell electrodeionization products and systems for GE Water & Process Technologies, based in Guelph, Ontario, Canada. He has been with GE and its predecessor Glegg Water Conditioning / E-Cell Corp since 1997. He is a graduate of Engineering Chemistry from Queen’s University at Kingston, Ontario, Canada.