Power Plant Achieves Optimal Performance with Electrodeionization Treatment Process

By VJ Nathan and Fred Wiesler

Brazos Electric Cooperative Power Plant in Cleburne, Texas, is a nominal 258 MW combined cycle gas-fired power plant operating on Automatic Generation Control (AGC) load requirements. The plant uses approximately 54 million gallons of water per year for boiler feedwater and NOx control of its combustion turbine.

Since boilers require highly purified feedwater to operate efficiently and avoid scaling, Brazos Electric determined that an electrodeionization treatment process would be required as part of the water treatment process to achieve optimal plant performance.

The power plant was originally commissioned in 1997. The demineralization plant consisted of a two-pass reverse osmosis (RO) unit with inter-pass caustic dosing followed by a conventional polishing electrodeionization (EDI) unit. Due to frequent scaling, however, the EDI system did not consistently meet the plant’s performance requirements. Shortly after the plant’s commissioning, a leased mixed bed polisher was installed to replace the electrodeionization system and meet the desired water quality.

Although the mixed bed polisher solved the previous challenges, its operation process warranted economic and sustainability concerns. Due to the high costs associated with mixed bed regeneration, the plant decided to reconsider using an electrodeionization unit. QUA’s Fractional Electrodeionization (FEDI®) was chosen for Brazos’s permanent EDI solution. The FEDI system comprises two trains of 10 dual-voltage FEDI stacks rated for 165 gpm each.

Historically, mixed bed polishers have been used as final polishing treatment on RO permeate water to produce high-purity boiler feedwater. Over the last decade, EDI has replaced mixed bed ion exchange technology and has become the technology of choice for this application. The main driver for this change is that EDI does not require chemical regeneration and eliminates the need to store and handle aggressive chemicals required for resin regeneration and the associated neutralization steps.

Acceptance of the technology has been slowed by its limited ability to treat water with high hardness, CO2 and silica. QUA’s patented FEDI technology was designed to overcome these limitations and allow the technology a wider operating window. This advancement paves the way for an increase in electrodeionization adoption for high-purity water applications in the power industry.

Brazos selected the FEDI technology because of its unique, patented, dual-voltage process. The dual-voltage design allows for a higher flexibility and tolerance to inlet water conditions, lowering the risk of hardness scaling, and improving the plant’s overall design economics and reliability. Additionally, it optimizes power consumption and reliability since the high voltage is only used when needed in the silica removal zone of the unit.

FEDI is a two-stage separation process where strongly and weakly ionized impurities are removed in two different stages (see Fig. 1).

In Stage 1, a significant amount of strongly ionized impurities, such as hardness, are removed. Stage 1 operates at a lower voltage and current and requires one third of the total power consumed. The acidic condition in the concentrate chamber of the first stage prevents scale formation, giving a higher hardness tolerance to the FEDI process. The patented ion exchange media construction used in the module further reduces hardness scaling potential.

Stage 2 removes weakly ionized impurities such as silica and boron. Higher voltage and current in this zone provides efficient removal of residual weakly ionized impurities as a significant amount of strongly ionized impurities have already been removed in Stage 1. The higher voltage also ensures that Stage 2 remains in a highly regenerated state, resulting in superior quality of product water. The high pH condition in Stage 2 helps with efficient removal of silica and boron.

The media developed for FEDI is a robust and stable ion exchange resin matrix that further supports the advantageous operation of this unit over conventional EDI. The FEDI membrane is made of heterogeneous ion exchange material and has a robust design due to fabric support.

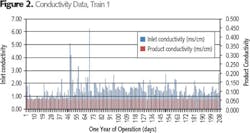

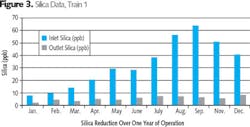

Since installation, the FEDI system has consistently produced a treated water quality in the range of 0.055 to 0.06 μS/cm conductivity and less than 10 ppb of silica (see Figs. 2 and 3). The plant operates at about 90 percent recovery. Reject is either disposed or recycled back to the front end of the RO; thus the recovery can exceed 98 percent with the net water loss being only the electrode rinse.

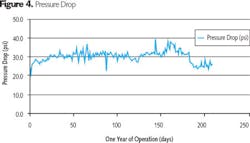

Figure 4 shows a constant pressure drop across the FEDI system over a year. This data confirms that no fouling is occurring inside the FEDI system, and thus no chemical cleaning was warranted. The system has been in successful operation for over six years and has consistently been producing high-purity water for the plant.

About the Authors: VJ Nathan is technical director at QUA. He can be reached at [email protected]. Fred Wiesler is director of sales and marketing for QUA. He can be reached at [email protected]. For information about QUA’s advanced membrane products, visit www.quagroup.com