Process Water System for Pembroke Power Station in South Wales

By Mike Hutt

At 2,160 MW, the power station at Pembroke in South Wales is the largest combined cycle gas turbine (CCGT) power plant in the UK. It was recently built for RWE npower. Following a number of previous contracts with both RWE and the main contractor, Hager + Elsässer (H+E) was chosen to design and supply the process water system to feed the gas turbines.

The design process itself incorporated a number of features preferred by the client in light of its experience operating H+E’s water treatment plants at other power stations and also some features preferred by H+E as a result of its own prior experience. In both cases, this was in keeping with the business philosophy of “continuous improvement.”

Since the supply of pure water is fundamentally important to the production of the high-quality steam required to drive the gas turbines efficiently, the design and ability of the water deionization plant to perform efficiently in the long term with minimal downtime is also of great importance to the business.

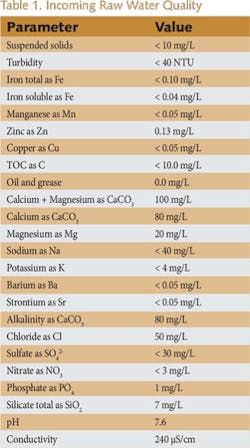

The incoming raw water quality that formed the basis for the process design is shown in Table 1.

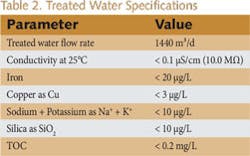

The required specification for flow and quality of the treated water is shown Table 2.

The water treatment system includes a number of carefully designed treatment stages, each of which contributes to an ever-improving water quality until the required purified water is obtained. These treatment stages include:

- Pre-filtration

- Sulfuric acid dosing

- PAC dosing

- Ultrafiltration

- Sodium hypochlorite dosing

- Anti-scale/bisulfite dosing

- Primary RO system (stage 1)

- Sodium hydroxide inter-stage dosing

- Secondary RO system (stage 2)

- Regenerable mixed bed polishers

- Wastewater neutralization system

First, particles are removed from the feed water via a coarse pre-filter. The water is then conditioned by dosing with sulfuric acid (H₂SO₄) to reduce the pH, enabling the following polyaluminum chloride (PAC) dose to efficiently flocculate/coagulate the dissolved organic matter and colloidal particles. Ultrafiltration with a nominal pore size of 0.02 μm is then used to efficiently remove those particles. The ultrafiltration modules are regularly backwashed with sodium hypochlorite (NaOCl) to maintain membrane performance at all times.

This “semi-treated” water is collected in an intermediate storage tank, which also provides water for fire-fighting, if ever necessary, before being repumped and further conditioned with both sodium bisulfite to remove free chlorine and anti-scalant to inhibit scale formation. The water is then fed to a primary (first stage) reverse osmosis unit with sodium hydroxide inter-stage dosing followed by a secondary (second stage) reverse osmosis step.

The fully treated water is checked for quality and then stored in a separate tank to ensure that large volumes are immediately available if required.

Product water from the twin-pass reverse osmosis system is then finally treated in two regenerable mixed-bed deionization polishers before flowing to a deionized water storage tank designed with sufficient capacity to enable high flow rate and volume supplies at times of critical need, thus helping to prevent any unplanned stoppages in power production.

The plant has been designed as a two-stream system, each delivering 60 m³/hour of treated water with a final purified water quality better than 10.0 MΩ (0.10 μS) on a continuous 24/7 basis. In normal operation, the streams are used in duty/standby mode. However, in periods of high demand, they can be used in parallel.

A typical H+E design approach for this type of water treatment plant places great emphasis on ensuring maximum overall plant efficiency. Clearly, the most important aspect is that the plant deliver the required flow rate and treated water quality at all times. After all, if high-quality deionized water were not constantly available, the turbines would have to stop operating and as a result, electrical power would not be generated. However, overall long-term cost of ownership and environmental impact are also increasingly important considerations that cannot be ignored.

Wherever practical, the equipment provided was pre-assembled before being delivered to site. This enables a substantial amount of factory testing to enable the highest level of quality before delivery to site and also minimizes the installation time required on site. Typically, such Factory Acceptance Tests (FATs) are witnessed by the client.

As with all water treatment plants, there is a need to treat the wastewater produced by the plant before it can be safely and legally discharged. In this case, that required a relatively simple collection, neutralization and monitoring system, which also formed part of the overall plant delivered by H+E.

Following delivery to site and completion of the installation, the plant was fully tested and commissioned. Following completion of all mechanical, electrical and process tests to ensure that the guaranteed quality of the water was being produced and that the plant as a whole operated correctly, it was then handed over to the client in 2012. The handover process included essential training of the operators and supervisors to enable them to ensure that the plant operate efficiently.

Since the system was originally commissioned and handed over, H+E has provided to the client onsite technical and engineering support, training for the operational staff, and also the occasional spare parts.

“Over 80 years of experience clearly shows that if the client chooses to use our engineers to provide process and maintenance support and spare parts, they will gain by maximizing plant life and minimizing long-term cost of ownership,” said Adam Martin, contracts director for H+E. “H+E benefits by ensuring that [the] plants we build continue to operate properly and our reputation as a supplier of reliable, high-quality systems is maintained.”

About the Author: Mike Hutt is managing director of H+E UK Ltd., part of water and wastewater treatment solutions provider H+E (www.hager-elsaesser.com), an Aquarion Group company. Hutt can be reached at [email protected].