Product Showcase

Baldor Electric has introduced a new adjustable-speed direct drive cooling tower system that improves reliability, reduces maintenance, runs quieter, and saves energy. By combining the technologies of the laminated-finned-frame Baldor•Reliance® RPM AC motor with a high-performance permanent magnet rotor design, this power-dense motor and power-matched adjustable speed drive replaces the right-angle gearbox and jack shaft installation found in conventional cooling towers. The fan couples directly to the motor and is controlled by the ABB ACS880 cooling tower drive to provide optimal variable speed performance that runs quieter with reduced energy consumption.

Baldor Electric Company

www.baldor.com

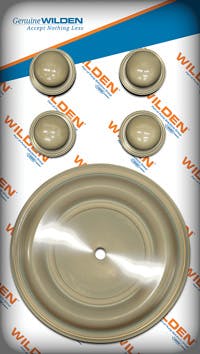

Wilden has launched a new parts kit program designed to speed delivery, lower costs and simplify ordering. The kits are available in either a Wet Kit (pictured) or Air Kit and can be applied to many different pump models to reduce the number of kits required. The Wet Kit replaces the Elastomer Kit and includes only elastomers located on the wet side of the pump such as diaphragms, balls, seats, gaskets, and O-rings. The Air Kit replaces the ADS Kit and contains a reduced number of parts, eliminating the air valve assembly and muffler plate.

Wilden Pump and Engineering

www.wildenpump.com

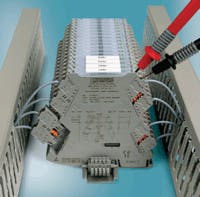

Phoenix Contact's new MINI Pro signal conditioners save space and make installation and configuration quick and easy for isolation, conversion, filtering, or amplification of analog signals. The conditioners measure just 6.2-mm wide, so they require up to 65% less space than traditional designs, and they have multiple configuration options that involve a DIP switch, PC programming or an Android app. With a voltage range of 9.3 to 30 V DC and an operating temperature range of -40 to +70˚C, MINI Pro signal conditioners are suitable for many industrial applications.

Phoenix Contact

www.phoenixcontact.com

GF Piping Systems has announced the new ecoFIT Industrial Polyethylene Piping System for broad-based applications. The new welded system features excellent chemical resistance, abrasion resistance and high-impact strength, even at low temperatures. It is available with a complete range of system components, including valves and connection options, and is easily installed with one of the company's three fusion joining technologies. It includes an operating temperature from as low as -58°F to as high as +140°F (-50°C to +60°C), and sizes range from 2" to 36" IPS, SDR11 and SDR17, with metric sizes ranging from 20 mm to 250 mm.

GF Piping Systems

www.gfpiping.com

Eaton addresses pipeline debris challenges with its MCS series of mechanically coupled strainers. Engineered for continuous operations, the high-flow strainers -- including the MCS-500 and MCS-1500 -- are designed to conserve valuable process water while optimizing plant performance. The MCS series of strainers feature fast-cleaning actuation that eliminates the need for dynamic seals. This technology provides quick and easy access for maintenance, minimizes potential leaks and requires few moving parts -- all of which contribute to a long service life. In addition, the eco-friendly design provides for low-waste operation, with no bags to purchase or discard.

Eaton

www.eaton.com

Magnetrol's Eclipse® Model 706 transmitter with Foundation fieldbus™ digital output communications is the first guided wave radar (GWR) transmitter to pass the Fieldbus Foundation testing using the latest Foundation fieldbus interoperability test kit ITK 6.1.1. This device offers all of the advantages of the standard 4-20 mA (HART) ECLIPSE Model 706, such as improved Signal to Noise Ratio (SNR), enhanced diagnostics (meets NAMUR NE 107) and full complement of overfill-capable probes.

Magnetrol International Inc.

www.magnetrol.com

Atlas Copco's B7-41/1000 Hurricane boosters help drill and service crews achieve high penetration rates with small equipment footprints. The boosters' small footprints also make them easy to transport between drilling and service sites. Underground water is diverted away from drill bits using the boosters' powerful output. The boosters generate more than 2,000 cfm flow at a maximum 1,000 psi to assist in pushing water up the borehole from hundreds of feet below ground. Removing underground water allows the down-the-hole air hammers to efficiently power through rock formations by reducing water pressure in the borehole.

Atlas Copco

www.atlascopco.com