High-Purity Water: Demanding Requirements Drive Treatment Advancements in Ultrapure Water Production

By Jeff Gunderson

Water characterized as "ultrapure" has been treated to an extreme level of purity, stripped of contaminants, particles and ions. In some cases, it is so pure that it can actually be characterized as an industrial solvent. Water treated to these exceptionally pure standards is critical to the semiconductor industry, which needs ultrapure water for chip washing, rinsing and etching processes.

Ultrapure water is also utilized in the production of flat panel displays and photovoltaic panels, and in the pharmaceutical industry, it is critical for injection and for cleaning process equipment. The power industry is yet another user, employing ultrapure water to serve as feedwater for steam boilers.

According to market research firm The McIlvaine Company, the global ultrapure water market will reach $4.9 billion in 2015 and is expected to grow at 8 percent over the next couple of years, driven largely by Asia -- and particularly China, where ultrapure water systems are increasingly needed in response to growth in coal-fired power plants and a boom in electronics and generic drug manufacturing.

"China is the major global purchaser of ultrapure water systems," said Robert McIlvaine, president of The McIlvaine Company. "Over the last five years, China has built more power plants than have ever been built in the United States. In power generation where steam is utilized, ultrapure water is needed for boiler injection. If the feedwater is not ultrapure, the boiler tubes will corrode, causing all sorts of problems."

In the U.S., The McIlvaine Company forecasts higher demand next year for ultrapure water systems as a result of expected growth in gas turbine and combined cycle power plants. "Gas turbines have a unique ultrapure water requirement," McIlvaine said. "In the air intake systems, fogging nozzles are used to lower inlet temperatures and thereby increase the weight of combustion. Small ultrapure water droplets are needed for evaporation in the air intakes because any impurities in the water lead to maintenance problems in the rotating elements."

Technologies and Treatment Sequences

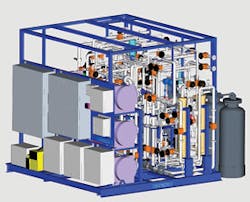

In treating water to ultrapure water standards, a range of advanced water treatment technologies is utilized and includes reverse osmosis (RO), filtration, ion exchange, electrodeionization (EDI), and further sophisticated treatment processes such as advanced oxidation, ultraviolet (UV) sterilization and membrane degasification.

Gary Pitts, global business leader of microelectronics with GE Water & Process Technologies, noted that leading-edge, advanced semiconductor manufacturing represents the pinnacle of the ultrapure water market and the most demanding and challenging water treatment requirements. "A robust series and sequence of water treatment technologies is required in order to elevate the purity of a raw water source to the quality levels that are necessary for state-of-the-art semiconductor manufacturing," he said.

The major categories of contaminants that are targeted for this segment of the electronics industry fall into the broad categories of total dissolved solids (TDS), metals, dissolved oxygen (DO), particles, and bacteria, according to Pitts.

"RO, EDI and ion exchange technologies are specifically used for TDS reduction, while UV photo-oxidation processes are employed for both the oxidation of organics as well as bacteria destruction," Pitts said. "Particle reduction can be accomplished through RO and a variety of filtration-based processes, including multimedia filtration, ultrafiltration and nanofiltration. Additionally, for oxygen removal, a gas transfer membrane system can effectively reduce dissolved oxygen levels to one part per billion or less."

In the development of a treatment train, Pitts indicated that a strategic approach is necessary in order to achieve a final, desired level of purity. "Each treatment technology is essential for removing a major contaminant, but conversely, each process will also create a minor throw-off contaminant," he said. "Because of this, the sequence of downstream technologies needs to be carefully considered, but final water should always be treated with filtration to reduce the particles to a precise, specified level."

Due to the very nature of the water produced, the selection of material components is also critical. "Ultrapure water stripped of ions is trying to reach ionic stability and will therefore tend to pull ions from the materials it comes into contact with," explained Pitts. "For this reason, we need to use very inert materials in the final steps. The water is so pure at this stage that even exposure to air would render it too dirty for use in semiconductor processes."

Treatment at the Atomic Level

In contrast to the pharmaceutical industry where ultrapure water standards are based on federal regulatory requirements, standards for microelectronics are driven by quality needs that are increasingly pushed by advancements in semiconductor manufacturing.

The water treatment challenges of today specific to microelectronics are related to metrology (the science of measurement) and manufacturing processes that are occurring at smaller scales, according to Alan Knapp, director of global business development at Evoqua Water Technologies. "As the line widths on chips become tighter and more microscopic, the quality requirements for process water, in turn, are being driven to such extreme levels of purity, that we are approaching the limit of what technology can actually measure," he said.

In microelectronics, there is now a real industry focus on targeting nanoscale particles, including silica and stainless steel, as well as achieving total organic carbon (TOC) concentrations of elements such as chloroform and urea that are down to sub-parts-per-billion levels Knapp said.

"In chip processing, the line widths are only 22 nanometers and are now being developed as small as 14 and 7 nanometers," he said. "Atoms are being moved around to make these chips. So with respect to ultrapure water, treatment is being driven to the atomic level. If the line width in a semiconductor chip is only 7 nanometers, a 10- nanometer particle is going to cause a defect."

System and Process Optimization

Given the very high capital and operational costs associated with ultrapure water systems, increasingly more focus is being placed on optimization as a strategy for achieving higher operational efficiencies.

"These systems are very complex and also very expensive to install and run on a day-to-day basis," said Pierre Kwan, a senior project manager at HDR specializing in ultrapure water solutions. "That's why we focus on working with owners and clients to right-size the equipment. This is important because an undersized system could lead to product limitations, while oversizing a system results in a very large capital cost that is underutilized."

Another approach includes the use of advanced instrumentation and smart monitoring --technologies that help ensure ultrapure water systems are operating at maximum performance regardless of differences in source water quality or variations in water production rates, according to Kwan.

"Smart monitoring enables us to track the performance of an ultrapure water system on a millisecond-by-millisecond basis, ensuring that the pumps are always operating at maximum energy efficiency and that the right chemical treatments are being applied in order to prevent RO clogging or membrane failures," Kwan explained.

Analytical instrumentation is especially significant to ultrapure water production in that operators can continuously monitor and appropriately respond to critical water quality fluctuations, thus avoiding production losses. "In the event there is off-spec water," Kwan said, "we can stop it from entering our process -- preventing a high-value electronics or pharmaceutical product from being inadvertently contaminated."

About the Author: Jeff Gunderson is a correspondent for Industrial WaterWorld. He is a professional writer with over 10 years of experience, specializing in areas connected to water, environment and building, including wastewater, stormwater, infrastructure, natural resources, and sustainable design. He holds a master's degree in environmental science and engineering from the Colorado School of Mines and a bachelor's degree in general science from the University of Oregon.