Water Briefs

Nation's largest egg producer settles CWA violations with EPA

The Environmental Protection Agency and Justice Department's Environment and Natural Resources Division announced a settlement with Cal-Maine Foods, Inc., one of the nation's largest egg producers, that resolves Clean Water Act (CWA) violations at the company's poultry egg production facility in Edwards, Miss.

Cal-Maine will bring the facility into compliance with its state-issued water discharge permit, significantly reduce nutrient pollution discharges, and improve environmental data collection and reporting practices. The company will also pay a $475,000 penalty to be split evenly between the U.S. Federal and Mississippi governments.

The settlement, a consent decree filed in federal court in the Southern District of Mississippi Northern Division, resolves alleged violations of Cal-Maine's CWA National Pollutant Discharge Elimination System (NPDES) permit at a large concentrated animal feeding operation that houses more than 2 million chickens.

Cal-Maine discharged pollutants from the production area into a tributary of a nearby creek without NPDES permit authorization and applied nitrogen-laden wastewater on fields at the facility during winter months when land application was prohibited and sometimes at rates that exceeded its permit requirements. It also committed hundreds of water sampling, record-keeping and reporting violations.

Giant Eagle commits to reduce water consumption

In celebration of Earth Day on April 22, Giant Eagle, Inc., one of the nation's largest food retailers and distributors, announced that it plans to reduce water consumption by 5 percent by July 2017, resulting in an anticipated conservation of millions of gallons of water.

According to Jan Eliasson, Deputy Secretary-General of the United Nations, demand for water is projected to rise by an estimated 40 percent by 2050. In an effort to accommodate this growing demand, Giant Eagle executed a five-month conservation program in which each of the eight pilot locations exceeded a 5-percent water savings. As a result, all corporately operated supermarkets will be retrofitted with water conservation equipment by June 30, 2015.

In addition to conservation efforts being put in place throughout Giant Eagle supermarkets, the company's WetGo car wash locations utilize water reclamation systems in order to make quality car washing more environmentally friendly. A single car wash uses approximately 50-percent fewer gallons of fresh water than typical car washes.

South Korea's largest nuclear power plant contracts with Veolia for water treatment services

Veolia, through its subsidiaries Veolia Water France and Veolia Water Korea, has been awarded a three-year operation and maintenance contract by Korea Hydro & Nuclear Power Co. (KHNP), the fifth-largest nuclear power supplier in the world, to supply water and wastewater treatment services to Kori Division, South Korea's largest nuclear power plant.

The contract covers freshwater demineralization and treatment to supply steam production pipes, as well as seawater treatment by electrochlorination to supply the cooling circuit of the nuclear power plant. Veolia is also in charge of the wastewater treatment facility, which does not include water that is in contact with nuclear fuel.

"KHNP's choice of Veolia is based on our expertise in the treatment of water in nuclear plants and our knowledge in security issues, which are illustrated through our significant contracts in France and Japan," said Régis Calmels, senior executive vice president, Asia, for Veolia. "This new contract confirms our expertise and reinforces our position in this growth market."

The capacity of the water and wastewater facilities operated by Veolia is more than 173,000 cubic meters per day, the equivalent of 55 Olympic-size swimming pools. A total of 73 employees will support the operations on site. Kori Division, which has a total of eight reactors, generates around 7,900 MW of electricity, which will represent 34 percent of the nuclear capacity in South Korea in 2015, equivalent to the electricity consumption of 8 million people.

Veolia group is a global specialist in optimized resource management. With over 179,000 employees worldwide, the group designs and provides water, waste and energy management solutions that contribute to sustainable development.

CONSOL Energy's Appalachian Basin operations certified by CSSD

The Center for Sustainable Shale Development (CSSD), a collaboration of environmental organizations and energy companies encouraging the development of shale gas resources in the Appalachian region, announced that it has certified CONSOL Energy's Appalachian Basin operations as having successfully completed its rigorous evaluation and verification process.

CONSOL Energy's certified operations must continue to adhere to CSSD's Performance Standards in the Appalachian Basin, integrating the organization's publicly available best practices into its long-term continuous improvement processes. CSSD will monitor adherence and continue to build and expand on its initial 15 Performance Standards. CSSD officially launched its certification process in January 2014.

The evaluation and verification process for CONSOL was conducted by auditor Bureau Veritas, a global specialist in testing, inspection and certification under contract to CSSD. The auditor conducted a pre-audit to familiarize itself with the company's management system and determine audit readiness of its Appalachian Basin operations.

Certification is valid for 24 months, after which companies can seek renewal. During the 24-month period, there is at least one assurance audit to ensure that conformance with the standards is being maintained.

Lab testing for dissolved gases in water aided by new ASTM standard

ASTM International, an international standards organization, has proposed a new standard that will provide a simplified way to test for dissolved gases such as methane and ethane in water.

Environmental and testing laboratories will be able to use the proposed standard (WK43267, Test Method for Measurement of Dissolved Gases Methane, Ethane, Ethylene, and Propane by Static Headspace Sampling and Flame Ionization Detection) to ensure that drinking water is safe in areas where hydraulic fracturing occurs.

Laboratories will use the proposed test to compare water from fracturing areas to water prepared with dissolved gases as a serial dilution. ASTM member Anne Jurek, senior applications chemist for EST Analytical, explained that the proposed test method presents an "effective and standardized" approach to testing for dissolved gases.

Subcommittee D19.09 on Water-Hydraulic Fracturing Fluids is currently developing WK43267, which will include a multi-laboratory study. All interested parties are encouraged to join in the standards developing activities of ASTM Committee D19 on Water.

MN city water wells show trace amounts of 1,4 dioxane

The city of New Brighton, Minn., announced that a contaminant of emerging concern, 1,4-dioxane (dioxane), has been detected in trace amounts in some of the city's wells. The likely source of the dioxane is the Twin Cities Army Ammunition Plant (TCAAP), which was identified as the source of other contaminants in New Brighton's drinking water supply.

Earlier this year, the city announced a settlement agreement with the United States Army to continue federal payment of the costs of owning and operating New Brighton's water treatment facility.

Thus far, no regulatory limit on the amount of dioxane permitted in drinking water has been set under the Federal Safe Drinking Water Act. However, the Minnesota Department of Health (MDH) has set an advisory limit of 1 part per billion (ppb). Recent testing conducted by the MDH and the city has detected dioxane in the drinking water at levels ranging from 2.9 ppb to 5.5 ppb.

Because the contamination likely originated at TCAAP, the United States Army is required to fund the costs of treatment as part of its settlement agreement with the city of New Brighton.

Molecular structure of water's liquid surface revealed in new quantum model

The National Physical Laboratory -- UK's national measurement institute -- in collaboration with IBM and the University of Edinburgh, has developed a new quantum model designed to reveal the molecular structure of the liquid surface of water.

The group has been working to make materials simulation more predictive and intuitive by developing a new class of materials model based on a single-charged particle, the quantum Drude oscillator (QDO), which mimics the way the electrons of a real water molecule fluctuate and respond to their environment.

This simplified representation retains interactions not normally accessible in classical models and accurately captures the properties of liquid water. The team used the QDO model to determine the molecular structure of water's liquid surface. The results provide new insight into the hydrogen-bonding topology at the interface, which is responsible for the unusually high surface tension of water.

This is the first time the QDO model of water has been applied to the liquid-vapor interface. The results enabled the researchers to identify the intrinsic asymmetry of hydrogen bonds as the mechanism responsible for the surface's molecular orientation.

This result demonstrates the exceptional transferability of the QDO approach and offers a promising new platform for molecular exploration of condensed matter.

Surface waters at risk from atmospheric releases of BPA, research finds

Research has found that elevated concentrations of Bisphenol-A (BPA), a chemical used in consumer products such as plastic food storage and beverage containers, have been discharged into local waterbodies by municipal or industrial wastewater.

With this, researchers from the University of Missouri and U.S. Geological Survey recently assessed water quality near industrial sites in the state of Missouri that are permitted to release BPA into the air. As a result, scientists now believe that atmospheric releases may create a concern for contamination of local surface water, leading to human and wildlife exposure.

The water sampling sites were selected based on their proximity to the Superfund National Priorities List or locations with reported atmospheric discharges of BPA as identified by the Environmental Protection Agency. Current or historical municipal wastewater treatment sites, which have been shown in the past to contribute hormonally active chemicals to surface water from urban or industrial sources, were also tested. Finally, relatively clean sites were chosen to serve as the control group.

Report predicts worldwide water pumps market to surpass $54B by 2020

According to a report recently published by TechSci Research, the global water pumps market is projected to surpass $54 billion by 2020. The growth is attributed to increasing industrialization in various end-use industries such as water and wastewater treatment, chemicals, power, and oil & gas, among others. Further, continuing increase in water and wastewater treatment service tariffs and growing replacement of water pumps in developed markets are expected to drive this market over the next five years.

The report, titled "Global Water Pumps Market Forecast & Opportunities, 2020," indicates that the Asia-Pacific region is currently the leading contributor in the global water pumps market, accounting for largest revenue share in 2014. Moreover, the dominance of Asia-Pacific can be attributed to high growth in water and wastewater treatment and power sector.

The region is witnessing high demand from developing countries such as China and India, wherein an upsurge in the infrastructural development projects in process industries, rising standards of living and growing urbanization are resulting in increasing water scarcity and higher demand for better sanitation, which is consequently providing the required impetus to water recycling projects.

Subsidiaries of Duke Energy sentenced for CWA violations

On Thursday, May 14, three subsidiaries of Duke Energy Corporation, the largest utility in the United States, pleaded guilty to nine criminal violations of the Clean Water Act at several of its North Carolina facilities and agreed to pay a $68-million criminal fine and spend $34 million on environmental and land conservation projects to benefit rivers and wetlands in North Carolina and Virginia.

Four of the charges are the direct result of the massive coal ash spill from the Dan River steam station into the Dan River near the city of Eden, N.C., in February 2014. Under the plea agreement, both Duke Energy Carolinas and Duke Energy Progress must certify that they have reserved sufficient assets to meet legal obligations with respect to its coal ash impoundments within North Carolina -- all totaling approximately $3.4 billion.

As part of their plea agreements, Duke Energy Business Services LLC, Duke Energy Carolinas LLC and Duke Energy Progress Inc., will pay a $68-million criminal fine and a $24-million community service payment to the National Fish and Wildlife Foundation.

Envirogen, Suez partnership targets power industry with water solutions

Envirogen Technologies, Inc., an environmental technology and process solutions provider, recently announced that it has entered into a Collaborative Alliance with Suez Environnement, a global specialist in resources management, where the companies will work together to deliver comprehensive, cost-effective water and wastewater treatment solutions to the North American power industry.

Further, they will carry out major environmental projects for electrical power generation facilities, with each company contributing proven, proprietary technology and extensive experience in developing high-performing, low-lifecycle-cost solutions.

The Alliance will combine Suez Environnement's capabilities in physical/chemical treatment technologies with Envirogen's expertise in biological treatment, but can extend to include the breadth of the technology portfolios of both companies. Near-term project targets for the Alliance include groundwater and landfill leachate treatment related to coal combustion residuals (CRRs) and flue-gas desulfurization (FGD) wastewater treatment. Both of these areas will be governed by new federal regulations coming online in the next 48 months.

Membrane cartridge market for food & beverage sector to reach $800M by 2020

According to new research published by the McIlvaine Company in the report, "Cartridge Filters: World Market," the market for membrane cartridges in the food and beverage industry is expected to rise to $800 million by 2020 in actual dollars, accounting for projected inflation. Further, the market in 2010 dollars is also projected to be $670 million.

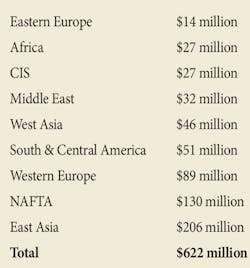

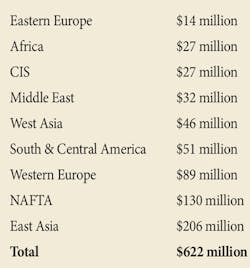

The provided table lists the most profitable markets in 2010 U.S. dollars.

By 2019, sales of membrane cartridges for the food and beverage industry are expected to exceed $200 million. East Asia is the fastest growing market, while NAFTA and Western Europe -- net exporters of processed food and beverages -- follow closely behind. Filter use in these two regions is therefore relatively high in proportion to the food consumed.

CA milk factory turned into 'zero water' plant with advanced technology

Nestlé, a multinational food and beverage company, has announced that it is investing in innovative technology to help reduce the amount of water it uses at its five water bottling plants and four facilities in the state of California where food or pet-care products are manufactured.

Accordingly, work is currently underway to transform the Nestlé USA milk factory in the city of Modesto into a 'zero water' factory, meaning the plant will not use any local freshwater resources for its operations.

The project is expected to save nearly 63 million gallons (238,000 cubic meters) of water each year, equivalent to 71 percent of absolute withdrawals in 2014. Around $7 million has been invested in the project, which is due to be completed by the end of 2016.

Nestlé has also realized savings of over 26 million gallons (100,000 cubic meters) of water each year at its factories in Bakersfield and Tulare, potentially reducing the plants' annual withdrawals by 12 percent compared to 2014 levels.

Nestlé opened its first 'zero water' plant last year in Mexico.