Products-Services ION EXCHANGE-FILTRATION

Zeolite media

Genesis Water Technologies has released its new GWT series natural zeolite media for water/wastewater treatment applications. The media is an inorganic micro porous alumino-silicate material with many unique filtration properties including a high cation exchange capacity (CEC) versus comparative zeolite media products. This media is a cost effective, environmentally safe solution for removing a variety of water contaminants.

Genesis Water Technologies

High flow filters

Graver High Flow Series filters have been certified by NSF International under ANSI/NSF Standard 61 as a drinking water system component. The filters feature a large geometry (6" diameter x 40" or 60" lengths) that makes them ideally suited for applications with large daily flow capacities. They are constructed of 100% pure polypropylene, contain no binders, adhesives or surfactants. All materials of construction are FDA listed for food and beverage contact and meet USP Toxicity tests for use in pharmaceutical applications.

Graver Technologies LLC

www.gravertech.com

RO membranes

Lanxess offers Lewabrane® Reverse Osmosis (RO) membrane elements for desalination and production of high quality water. The Lewabrane RO B090 HF 4040 product type consists of spiral-wound polyamide composite membranes with a surface area that exceed other commercially available elements by almost 6 percent. The bigger surface area results in higher water productivity and creates a superior permeate flow rate. HF (high flow) and HR (high rejection) membranes are available with surface areas of 370, 400 and 440 square feet. The high rejection versions offer more than 99.7% salt rejection measured under standard conditions.

Lanxess

http://lanxess.us

Filtration system

The WWETCO FlexFilter™ from WesTech uses a synthetic compressible media to capture solids in a high rate filtration process. Rising influent applies hydrostatic force to the outside of tapered flexible bladders causing the media within the bladders to compress loosely at the top of the filter, with a tighter porosity gradient through the depth of the filter. This tapered compression provides for a filtration bed that is more open at the top of the filter, graduating to more densely packed synthetic media in the deeper portions of the filtration bed. The simple gravity system includes a unique backwash system involving an air scour coupled with a high energy wash cycle and specialized backwash troughs to minimize the volume of backwash water needed.

WesTech Engineering Inc.

www.westech-inc.com

Chromate selective resin

ResinTech's chromate selective resin, ResinTech SIR-700, now meets NSF/ANSI-61: Drinking Water System Components - Health Effects for use in all potable water applications. The media has been used successfully at Superfund sites to remove hexavalent chromium from groundwater, in one case offering projected savings to the federal government of up to $20 million. Its unique chemical structure provides tremendous throughput capacity with the ability to load more than 7 pounds of chrome per cubic foot of media under ideal conditions.

ResinTech Inc.

www.resintech.com

Bag filters

Hayward Flow Control has launched its new FLV Series Bag Filters. The new filters feature a one-piece injection molded platinum GF PP (Glass Filled Polypropylene) body in sizes 1 (16") and 2 (32"). Unlike traditional metal and plastic filters, the series offers a true-union design for multiple end connections and sizes as well as quick installation or removal. They are available in the size range of 1 1/4" through 4" in socket, threaded and flanged connections, as well as optional drill and tap NPT (Offset) ports for interchangeability with existing installations. The FLV series can be ordered as a Simplex through Quadplex unit.

Hayward Flow Control

www.haywardflowcontrol.com

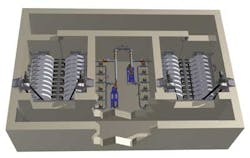

Compressible media filter

Schreiber's Fuzzy Filter is a compressible media filter for water and wastewater treatment systems. Media compression permits adjustment of the filter pore size to meet process changes. The filter is very high rate, compact and modular, and is applicable to a wide variety of water and wastewater applications. Operating in an up flow design, the filter achieves an exceptionally high rate of solids removal through the use of synthetic fiber spheres. With loading rates 30-40+ gpm/ft2, the filter requires 20% of the floor space as sand filters. Applications include tertiary wastewater treatment, influent river water, Pre-RO water cleansing, contaminated stormwater, membrane backwash water and cooling water side stream filtration.

Schreiber LLC

www.schreiberwater.com

Water filters

Orival automatic self-cleaning filters can be used to treat effluent for use in service water applications, including cleaning devices on primary bar screens, spray bars on sludge belt presses and seals on pumps. The company designs filtration systems for large or small flow rates to protect nozzles and seals at trickling filter and activated sludge treatment facilities.

Orival Inc.

www.orival.com

Filter cleaning

Blue Earth Labs' filter and trough cleaning product, Filter Fit®, is a low-corrosive, NSF 60 certified solution engineered to remove biofilm, scale, algae deposits and potassium permanganate stains from filtration basins, troughs, clarifiers and other water treatment plant surfaces. The cleaner is applied to surfaces off-line in a low-pressure spray-on/rinse-off process that is safe for virtually all painted and unpainted surfaces including steel, concrete and fiberglass.

Blue Earth Labs

www.blueearthlabs.com

Belt filter

Blue Water Technologies has launched its latest proprietary product line, the Eco MAT™ rotating belt filter (RBF). The filter is a clarification process with a small footprint that outperforms traditional primary systems for sewage treatment as well as screens and solids-separators in industrial facilities. Four unique models range in sizes suitable for small communities to large cities. There is no limitation in flow capacity designs. The RBF can be customized for varying flow and operational redundancy, facilitating the highest level of treatment for flows in excess of 3 mgd in a single unit.

Blue Water Technologies

Skidded filter systems

Keystone Filter offers small skid mounted systems combining nanofiber, polypropylene, polyester, microfiberglass, and/or cellulose filter cartridges and filter housings constructed of a variety of materials. These pre-packaged, skid mounted systems can incorporate multiple technologies including filtration, membrane purification, ion exchange, and disinfection provided by UV or ozone. Skid mounted systems can be used as a standalone unit or as additional pretreatment to enhance the performance of existing systems.

Keystone Filter, Met-Pro Corp.

www.keystonefilter.com

Gravity sand filter

The Gravity Sand Filter from Headworks BIO is an upflow, continuous backwash, granular media filter that efficiently removes suspended and colloidal solids while providing a continuous supply of filtered water. The filter is available in various circular and rectangular models for different flows and applications.

Headworks BIO Inc.

www.headworksusa.com

Tertiary filters

The Aqua MiniDisk tertiary filter features OptiFiber® pile cloth media and is designed to provide economical treatment of smaller flows with the added advantage of retrofitting existing traveling bridge sand filters. The modular design of the filter retrofits neatly into existing 9-foot-wide concrete traveling bridge filter basins, providing more than two times the hydraulic capacity of the original sand filters. The filters achieve low effluent TSS, NTU and phosphorus while offering high solids and hydraulic loading rates, minimal operating and maintenance costs, and a fully automatic PLC control system. The filter is ideal for municipal reuse and phosphorus removal applications, and is also available in steel package units for new construction.

Aqua-Aerobic Systems

www.aqua-aerobic.com

Sand filtration

Parkson Corporation has redesigned the DynaSand® sand filtration system to reduce backwash water volume by as much as 90%, according to the results of a recent trial. The new DynaSand® EcoWash™ minimizes energy use and reject flow by triggering the backwash cycle only for short periods of time. The control system activates the backwash cycle for media washing only when it is required, based on time or the headloss in the filter's feed channel. When the filters are not backwashing, the level of turbidity drops because the filter is actually able to capture more solids in the existing bed when compared to continuous backwash operation. For operators, the new system requires significantly less attention, as the system monitors conditions and cycles through stages automatically.

Parkson Corp.

www.parkson.com