Using Membrane Technology to Find Profit in Process Waste

Figure 1. Reverse Osmosis of Whole WheyBy Denise Haukkala[Web Exclusive - Industrial WaterWorld - Sept. 1, 2009] -- It's often said one man's trash is another man's treasure. As recently as the 1960s, cheese whey was truly considered a waste product suitable only for disposal. When environmental regulations expanded, reverse osmosis (RO) initially was viewed as a necessary extra cost to allow discharge of the process water. Today, there are dairy plants using RO or nanofiltration (NF) technology that produce more profit from their whey protein concentrate (WPC) and whey protein isolate (WPI) than from their cheese.What changed in such a short period of time can be instructive as to how many new opportunities exist and are developing for membrane processing outside of traditional industrial and municipal water applications.

In the case of RO and cheese whey, nutritional science discovered numerous benefits to the proteins and lactose in whey. Combined with the science was an expanded health and fitness awareness to provide the spark to discover profit in the whey discharge stream.

RO is still used in more classic water processing applications in cheese and dairy plants. It required a paradigm shift, however, to design a process intended for the retentate where numerous new process applications have evolved. Figure 1 provides a diagram of a basic whey concentration process.Figure 2. Osmotic Pressure as a Function of Solute Weight Percent

The RO and NF membrane act as concentrators of the whey to about 20-25% total solids. While RO membranes effectively concentrate the whey stream, an NF membrane will be used to partially demineralize the whey while retaining the proteins and lactose. Desirable minerals, such as calcium and magnesium will be retained with NF while the majority of the salt content in whey will pass to the permeate.

As is the case for whey, a membrane process can save significant time and energy compared to the use of an evaporator alone. Evaporators, though, are still necessary to complete the concentration process, since the osmotic pressure, feed viscosity and fouling potential become very energy and cost intensive above 20-25% total solids (depending on the consumable involved). Figure 2 presents a graph highlighting one aspect of these concentration process limits by displaying the increase in osmotic pressure for various weight percents of different solutes.

In addition to a different approach to membrane processing, the membrane technology needed to adjust to the new processing realities in a consumables processing plant. Elements were needed that could Figure 3. DOW™ Food and Dairy RO-8038 Elementbe cleaned daily, were fabricated to minimize microbial expansion, and could be effectively sanitized either chemically or thermally. Items such as the brine seal and end cap needed to be removed, membrane leafs trimmed, and other dead spaces removed. Vessels that were fiberglass wound became stainless steel.

Figure 3 presents the modern Dow evolution of a consumables RO element, the DOW™ Food and Dairy RO-8038. The hard outer shell is designed for the most harsh feed process conditions and increases the membrane robustness. Threading on the outer shell along with membrane trimming and other design changes target elimination of dead spaces. The element function is to maximize the protein, sugar and mineral retention whilst optimizing plant operating efficiency.

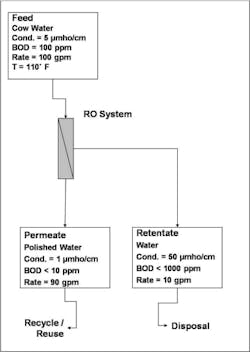

Figure 4. Reverse Osmosis of Cow Water Evaporator Condensate

Water processing RO systems are often prevalent in other portions of dairy plants. Process water may be treated for plant use to provide better finished product consistency or to address downstream treatment concerns, such as silica or scaling. To reduce disposal costs and to recover water for reuse RO systems are utilized to polish RO permeate and/or evaporator condensate. Figure 4 presents a basic diagram of an RO process for polishing evaporator condensate of cow water. These polishing systems typically operate around 90% recovery and are intended to reduce the BOD content to less than 10 ppm.

In addition to whey, other consumable concentration applications like juice, maple syrup, tea and egg whites have developed for membrane technology. Principles of membrane process concentration, partial component separation and process water treatment for final product consistency have expanded to numerous applications including wine, beer, and soft drinks.

Plato once said that necessity is the mother of invention. That expression is as true today as it was in ancient times. As the world continues to evolve and industrialize, regulations expand, and certain resources become scarce, demand will continue to find innovation with membrane processing.

Whether addressing water, wastewater or other process needs, recycling, reducing and reusing isn't just green. It has become profitable. Already there are signs of abundant new opportunities for membrane processing. Anti-freeze recycling, lower energy specialty product separations, and metal recovery in mining are examples of the next generation of profitable membrane processes. How many more diamonds are waiting to be unearthed from what formerly were viewed simply as lumps of coal? IWW

About the Author:

Denise Haukkala is in technical service and development for Dow Water & Process Solutions. She has 10 years of experience with The Dow Chemical Co. and has held a number of research positions focused in analytical sciences, chemo-rheology of thermosets, polymer application development, and technical service and development for FILMTEC™ membrane products. Contact: 800-447-4369, [email protected] and www.dowwatersolutions.com

###