Veolia to supply raw water and demineralized water systems for Hickory Run Energy power station

PENNSYLVANIA, DEC 13, 2017 -- Kiewit Power Constructors Co. has chosen Veolia Water Technologies, Inc. to engineer and procure both the Raw and Demineralized Water Treatment Systems for Hickory Run Energy's new natural gas combined-cycle power plant, Hickory Run.

The 1,000 mega-watt combined-cycle natural gas facility, located in Lawrence County, Pennsylvania, is currently in the construction phase with a commercial operation date of April 2020. When completed, Hickory Run will provide efficient, clean and reliable power to the PJM Electric Market.

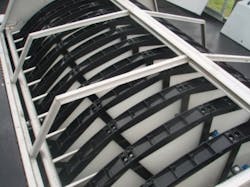

The 5,000-gpm Raw Water Treatment System at Hickory Run will incorporate Veolia's state-of-the-art proprietary Actiflo® high-rate clarification, Hydrotech™ Discfilter and AnoxKaldnes™ Moving Bed Biofilm Reactor (MBBR) technologies. The feed water to the plant will be effluent from the local public owned treatment works (POTW) and will be used as plant cooling water and boiler feed water after demineralization. By utilizing treated sewage effluent instead of fresh water, the power station is able to conserve 5,000 gpm of fresh water resources.

This project is just one example of many recycle and reuse projects that Veolia implements worldwide. "Veolia is committed to helping industries manage their water and energy resources, in line with our mission of Resourcing the World – developing access to resources, protecting and replenishing them. Veolia's vast experience in the power industry, coupled with our proven technologies for tertiary municipal effluent treatment, offers significant benefits to the project," said Klaus Andersen, CEO of Veolia Water Technologies, Inc.