Production processes that use municipal water as an ingredient normally dechlorinate it before sending it to the reverse osmosis (RO) systems. This process involves activated carbon towers, which can be a food source for microorganisms. Water that comes out of carbon can be susceptible to recontamination. When that water reaches the reverse osmosis membrane, flow velocity is slowed, providing ample opportunity for microorganisms to attach and start forming biofilm on the membrane surface. Any carbon sediment that escapes the activation process can also degrade the reverse osmosis membrane.

Why RO prefiltration matters

To protect the RO system, prefiltering source water is a vital safety and preventive maintenance step. In fact, the U.S. Food and Drug Administration (FDA) requires reverse osmosis prefiltration in the food and beverage industry and in processes where water for injection is used, such as pharmaceutical production. Prefiltration not only reduces the chance of biofilm formation, but it also minimizes the risk of other particulates damaging the delicate reverse osmosis membrane.

Because reverse osmosis membranes are costly to replace, it is best to pay close attention to the protection level that a prefilter offers. Although prefilters may seem like a commodity compared to the sophisticated RO system, they can actually be some of the most vital filters in a process.

RO prefiltration options

Industry standards recommend a 5-micron prefilter on RO systems, that is, one designed to remove contaminants 5 microns in diameter or larger. For many years, the traditional choice for RO protection has been a cartridge melt-blown filter. This is a solid polypropylene cylinder injected with nonwoven polymer fibers.

Figure 1. Donaldson Company’s line of filters

Due to advancements in filtration technology, pleated media filters are becoming a recommended option for RO prefiltration. Unlike solid melt-blown filters, which are a single piece of media, pleated media filters are like fabric arranged in folds inside a polypropylene cage. This engineering increases filtration surface area and translates into benefits for operations that maintain RO systems. The following are some advantages:

Improved capture retention

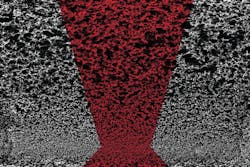

Melt-blown fibers may be incapable of retaining microorganisms to a validated point, rendering them less reliable in reducing biogrowth on reverse osmosis membranes. Pleated filters, on the other hand, can be manufactured to meet a better-defined micron cutoff range. Filtration engineers have developed pleated media with layers of graduated porosity, composed of larger pores on the upstream side and narrowing to smaller ones on the downstream surface. This structure improves the media’s depth-loading qualities and enables more consistent retention, which better inhibits biofilm growth. (See Figure 2.)

Figure 2. This asymmetrical filter media structure enables more consistent retention, which better inhibits biofilm growth.

Retention is important because even minute quantities of surviving microbes can multiply quickly in the right environment. RO systems can become overburdened with biogrowth in just weeks, and each replacement is costly. Plants that heavily rely on their RO modules to produce a product will want to avoid taking their systems offline more frequently than necessary to deal with biofilm.

Verifiable performance

It may be surprising that there is no widely accepted standard dictating how filter manufacturers measure and report efficiency — the percentage of particles removed by the filter from a challenge stream. However, because of their precise manufacturing process, more advanced pleated RO prefilters can be validated for efficiency.

Testing has shown that common melt-blown prefilters on the market widely vary in performance. Filters from five different manufacturers, all labeled "1 micron," have ranged from below 20 percent to above 98 percent in efficiency. The labels "nominal" and "absolute" for filters are just as subjective — similar to the claim of "low fat" in food labeling.

The consistent media of recently developed pleated filters permits suppliers to conduct and report test data on a voluntary basis. In Donaldson’s liquid filter line, for instance, an absolute-rated filter that claims a capture size of 1 micron will remove 99.98 percent of the particles 1 micron in diameter or larger. The filters are periodically retested to confirm this performance. (See Figure 3.)

Figure 3. Dirt-holding capacity, reduced differential pressure and longer life of a pleated prefilter

When selecting a filter, users should always look for a verified efficiency rating next to the micron size on the filter’s technical data sheet. Identical-micron filters may vary in the percentage of particulates they actually capture, so it is important for operators to source their filters from a manufacturer that conducts and publishes its retention efficiency data with the corresponding micron size.

Longer filter life

If a reverse osmosis membrane is carefully protected, it should typically last up to two years before it needs replacing. A membrane that fouls every six months or within a year may signify a substandard filter. There may be a 5-micron rated element in place, for example, but it is possible the filter may be providing just 50 percent efficiency for 5-micron particulates.

For optimal RO membrane protection, filtration engineers recommend installing a 1-micron absolute-rated pleated filter either in place of the melt-blown filter or directly after it, before water hits the RO membrane. Doing so will extend not only the life of the reverse osmosis membrane but also the prefilter itself due to the pleated design. Melt-blown prefilters typically last several days; therefore, it is not unusual for plants to routinely schedule a weekly prefilter change based on its performance history. A high-quality pleated prefilter can be expected to deliver peak efficiency for at least twice that long.

With pleated or melt-blown filters, it is good practice to monitor pressure drop in pounds per square inch (psi) across the filter. A downstream gauge reading below a predetermined psi will indicate that a filter has fouled and prompt replacement.

Cost factors

Because of their media design and precision manufacturing, pleated filters have a higher initial purchase price than melt-blown filters. Consequently, a processing plant may choose the least expensive melt-blown prefilter available and trust their reverse osmosis membrane to remove remaining contaminants. While that is one potential strategy, it should be verified by a comparison of overall costs.

When calculating potential return on investment on a pleated filter, the following are long-term cost factors to consider:

- Reverse osmosis membranes can last up to twice as long when protected with prefiltration that significantly reduces biofilm and wear from carbon particulates.

- Production downtime for replacements can potentially be reduced by half or more because of longer-lasting RO membranes and prefilters.

- Labor and maintenance can be saved or redirected due to longer prefilter and RO membrane replacement intervals.

- Risk of product contamination is minimized because of microorganism capture upstream, before colonies can replicate.

Each production process will be unique, so determining actual cost savings may be a matter of experimenting with a higher-grade pleated prefilter and comparing its performance over time with the previous melt-blown prefilter.

Conclusion

Water is essential for life and provides an ideal growth environment for both desirable and nondesirable organisms. The removal of chlorine from source water can introduce harmful microbes and carbon particulates that place a burden on expensive RO systems.

More robust prefilter technology can protect RO modules, and the elements have greater verifiable capture retention and service life. Pleated designs can minimize risks at a lower overall cost. Truth in labeling from a filter supplier and requesting both a micron rating and tested capture efficiency are also important.

Colter Marcks is the engineering manager for Donaldson Company’s Process Filtration division. His filtration product development experience is focused on technologies, applications and regulations related to liquid filtration, culinary steam and sterile air production in the food and beverage industry.