New Scale Prediction Software for High Recovery RO Applications

By Matt James, PMP, Research and Development Project Supervisor, Avista Technologies

Water scarcity is a massive global challenge driving a significant shift in the water treatment industry to find sustainable solutions to maximize water production. New technologies and applications to recover higher quantities of clean water are continuously being explored.

Reverse osmosis (RO) is a mainstay technology due to its ability to quickly recover large amounts of clean, high purity water. RO systems now reach higher water recovery — upwards of 98% — using new technologies like high pressure membranes, unique variable recovery applications and zero liquid discharge technology.

As recovery rates increase in the RO process, new challenges arise such as exceedingly high saturations of salt in the brine that can form scale on membrane surfaces.

Sparingly soluble salts in high recovery RO systems, called scale, can precipitate on the membrane surface. The effects of scale increases energy consumption, cleaning chemical costs, membrane replacement costs, and reduces water quantity and quality. To help prevent scale from forming, antiscalants can be added to delay scale precipitation until the water has left the system. As recovery rates are pushed to their limits to treat challenging water sources including industrial and municipal waste, system operators are seeing difficult scales emerge. These scales require advanced saturation prediction calculations to correctly predict and prevent.

RO system engineers and operators depend on chemical dosing programs provided by chemical suppliers to select the right product based on the system’s feedwater analysis. These programs use industry accepted water math combined with practical chemical application knowledge.

Avista™ Advisor™Ci Chemical Dosing Software

Originally introduced by Avista Technologies in 2000, AdvisorCi chemical dosing software uses cloud computing and machine learning to provide users with fast and accurate scale predictions. This proprietary chemical dosing software with complex ion technology maximizes RO system recovery for even the most challenging applications. AdvisorCi predicts precise dosing and use rates for Avista membrane chemicals. It calculates the saturation potential of a feedwater based on the free concentration of ions, overcoming a critical weakness in contemporary indices that consider the total analytical value, which typically includes ions that are bonded.

When compared to spreadsheet-based industry standard calculations, the accuracy of complex ion pairing results in reduced chemical consumption, lower energy requirements, and higher water savings for high recovery applications. Traditional saturation calculations assumed that ions are distributed solely based on the activity coefficient governed by the ionic strength of the solution. Because of this, ions were incorrectly assigned to multiple oppositely charged ions simultaneously using analytical values. This model worked sufficiently well for low recovery systems with low TDS (total dissolved solids) feed streams but struggles for modern systems. Complex ions correctly calculate the distribution of ions and soluble, insoluble and intermediate salts. The computational power required for this type of calculation was not user friendly without the use of cloud computing because each calculated recovery can take up to 100,000 iterations to accurately calculate ionic distributions of complex waters. Complex ion calculations allow users to see the most accurate saturation calculations available in the industry which leads to overall lower antiscalant doses, higher possible system recovery, and optimal product selection which will reduce environmental impact for membrane system operations.

Introducing the AdvisorCi 3D Multivariable Model

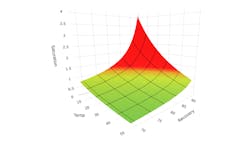

In the latest AdvisorCi software update, users will find a new Multivariable Model that allows users to create a 3D graph of two system parameters at one time. Users can see the impact of changing system recovery and feed pH or temperature on scale saturations in one model. Prior to this feature, users had to change pH or recovery and then recalculate a new data set to examine the change to brine saturations and dosages. With the Multivariable Model, users can make multiple changes in one calculation and examine the impact on eight different common scales seen in RO systems including carbonate, sulfate, phosphate, and silica scales. The use of cloud computing allows the multivariable model to process approximately 500,000 data points in a matter of seconds, giving users the most accurate data needed to optimize their system.

Module for proper cleaner selection

In addition to scale modeling for antiscalant products, the AdvisorCi software calculates RO cleaning chemical needs. This is made possible with data collected from extensive lab testing, results from thousands of RO element autopsies, onsite membrane cleans, and full element tests. Users select the foulants and cleaner preferences (i.e., powder or liquid), then AdvisorCi recommends the most optimal cleaner for that RO system. The right cleaner selection improves high recovery applications by fully removing foulants and scales from membrane surfaces, which will increase membrane performance and time between cleans.

High recovery system health considerations

Accurate scale prediction and cleaner selection is critical to the successful operation of RO systems, especially those operating at high recoveries. Here are other system health considerations for a successful high recovery application:

- Perform routine water analyses (seasonal changes).

- Verify particle counts and turbidity across the treatment (particle counts < 100 pc/mL; turbidity < 0.2 NTU).

- Provide accurate scaling projections including salinity changes and temperature variations.

- Determine the type of mineral deposits on membrane if scale is suspected.

- Optimize cleaning procedure to restore membrane performance.

- Monitor system performance with data normalization.

For system engineers, plant managers and operators, the right RO chemical selection, accurate chemical forecasting, proper application procedures and operation data monitoring creates a sustainable solution to maximize water production and reduce environmental impact.

Matt graduated from Baylor University in Waco, Texas, with a degree in Chemistry. He joined Avista Technologies in October 2012. Over the years, Matt has worked on the development of new antiscalants with a focus on Avista AdvisorCi Software. He evolved the software into a more complex ion calculation engine, which transitioned Advisor3 to Avista AdvisorCi in 2015. Finally, Avista AdvisorCi Online was launched in 2021, which moved the powerful calculation engine capabilities online.