Steam, air and water filtration for improved food processing safety

Under a September 2016 provision of the Food Safety and Modernization Act (FSMA) passed in 2011, nearly every U.S. facility that processes food or beverages is required to have a written hazard analysis and risk-based prevention control plan (HARPC) in place.1 For facility operators, this means identifying all "critical control points" in their manufacturing processes where contamination could potentially occur and proactively addressing them. Thus, filtration is critical in these areas.

While FSMA is the most recent and sweeping food safety regulation, previous Food and Drug Administration (FDA) regulations also apply, including the Code of Federal Regulations (CFR) Title 21, Inspection Technical Guide on reverse osmosis, and the FDA Food Code Chapter 5 on water, plumbing and waste. Regulations may outline general requirements, but details on exactly what constitutes "sanitary grade" are contained in numerous professional guidelines and standards.2 The most widely applicable are those from Safe Quality Foods (SQF) and 3-A Sanitary Standards.

Areas of risk for food processing

Food safety has put filtration in the spotlight — as it should be. Water in liquid and steam forms is prevalent as an ingredient, cooking method and cleaning agent. Air powers pneumatic equipment, moves product, and adds texture. Water, steam and air can all transport dirt and microbials into products or packaging or deposit them on food contact surfaces.

Every application is unique, and process owners may find additional areas in which filtration is critical, but generally, the following are three filtration-critical regions in a food and beverage process:

- Prefiltration: In utility rooms or bulk storage areas where water, steam and air sources are first brought into the facility or generated.

- Intermediate filtration: At process steps where water, steam and air travel through piping or other equipment before making direct contact with food or food contact surfaces.

- Final filtration: Near the end of processing, where a final opportunity exists to manage surviving contaminants.

Filter ratings and certifications: Key distinctions

After a process owner identifies necessary filter locations, the next task is determining appropriate micron and efficiency ratings for each control point. This is an important but sometimes confusing topic.

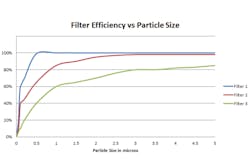

A micron rating reflects the particle size that a filter is designed to capture. Efficiency is a value: the percentage of capture actually achieved in that micron range. The market offers multiple filters labeled 1 micron, with efficiency performance ranging from 85 to 99.98 percent in the 1 micron range (see Figure 1). The terms "absolute" and "nominal" are also important in labeling. Absolute filter media can achieve efficiencies of 99.98 percent or greater, while a nominal filter typically provides 60 to 98 percent efficiency at that same micron size.

Figure 1. Filter efficiency versus particle size

Finally, it is paramount to look for filter elements and housings with 3-A certification (see official 3-A symbol in Figure 2). Only 3-A certified equipment is independently verified to meet 3-A Accepted Practices for "sanitary design," which minimize harbor points where bacteria can gather and multiply. The standard not only specifies stainless steel, but also an exacting quality of finish and connections.

Figure 2. This symbol from 3-A Sanitary Standards Inc. means the processing equipment has been third-party verified to meet 3-A Accepted Practices.

"3-A compliant" is not a legitimate claim, and the 3-A Sanitary Standards Institute recently issued a warning about knock-offs of its symbol.3 Products from manufacturers cited in the warning may have:

- Poor welds with rough areas.

- Bead-blasted surfaces rather than electro-polished.

- Pipe joints with a flange or national pipe thread (NPT) instead of sanitary clamps.

“Using cheese processing as an example, there are critical control points on a food production line where liquid, steam and air filtration can reduce the risk of contamination.”

Filtration map for cheese processing

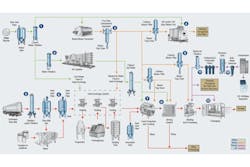

Using cheese processing as an example, there are critical control points on a food production line where liquid, steam and air filtration can reduce the risk of contamination in a consumable product. (The following numbers correlate to the critical control points on the filtration process map shown in Figure 3.)

Figure 3. Filtration process map

1. Prefiltration of source water

Municipal or well water that is brought in for ingredients, feed boilers or cleaning systems can harbor dirt, rust and scale. Coarse prefiltration should be installed to remove 95 to 98 percent of contaminants at this earliest stage. Prefiltration helps protect plant equipment from clogging and corrosion, and it lightens the load on finer filtration elements downstream.

Filtration option: Nominal polypropylene depth filters of 10 microns. Source water with heavier debris may require a series of 50-, 20- and 10-micron prefilters. Elements should be polypropylene pleated filters in a stainless steel housing.

“Prefiltration helps protect plant equipment from clogging and corrosion, and it lightens the load on finer filtration elements downstream.”

2. Prefiltration of reverse osmosis water

Ingredient water is typically purified through reverse osmosis (RO). The FDA requires that feedwater be adjusted to proper pH and be prefiltered. The amount of total dissolved solids (TDS) and suspended materials in the feedwater after prefiltration should be controlled within the designed limits. Prefiltration also helps protect the longevity and efficiency of RO equipment.

Filtration option: Absolute polypropylene depth filters at 1 micron in a stainless steel housing.

3. Steam prefilter

As the steam condenses inside the piping, water needs to be removed from the system. Water in the steam system is hard on valves and components and reduces the energy efficiency of the steam. An entrainment separator with a prefilter inside of it will remove piping debris and condensation before it reaches the culinary-grade steam filter. A steam trap should be used on the housing drain to divert condensation to the condensate return loop.

Filtration option: High-capacity absolute pleated filter of 25 microns in a stainless steel housing, installed in a coalescing orientation with steam trap.

4. Culinary steam filter

The heat energy of steam can degrade boilers and other system components, including carbon steel pipes, sealing elastomers and pressure-reducing valves. Even small amounts of contamination can clog wands and spray balls for clean-in-place (CIP) and sterilization-in-place (SIP) systems, rendering them ineffective. Culinary-grade steam requires the removal of 95 percent of particles 2 microns in size or larger.

Filtration option: A stainless steel filter capable of capturing at least 95 percent of particles 2 microns and larger. Absolute depth filter elements rated at 5 micron meet this requirement. The drain should have a steam trap to remove condensation.

5. Raw milk filter

Similar to incoming water, raw milk may harbor organic and inorganic particulates picked up during supplier handling and transportation. To protect milk quality and process equipment, filtration is required before pasteurization or other heat processes.

Filtration option: Nominal propylene depth filters of 25 to 10 microns in a stainless steel housing.

6. Storage tanks

Holding tanks can be a breeding ground for bacteria that enter during filling and emptying. Air or nitrogen is useful as a protective "blanket," but first requires filtering. In addition, a tank vent is necessary to keep airborne microbes out while equalizing tank pressure as volume changes.

Filtration option: Absolute 0.2-micron sterile air tank vent filter.

7. Curd production

A heat treatment using hot water and/or culinary steam regulates the size and acidification of the cheese curd. Before injection, the water or steam should be filtered to reduce impurities picked up in process piping.

Filtration option: Culinary steam produced using 5-micron absolute rated steam elements in a stainless steel housing and steam trap or sterile water filtered down to 0.2 micron using PES membrane cartridges.

8. Brining and rinse

Sanitary water is used in the brine solution and as a post-brining rinse to remove excess whey. Steam may be used to maintain a precise temperature during this process. Water and steam should be filtered just prior to direct food contact.

Filtration option: Culinary steam produced using 5-micron absolute rated steam elements in a stainless steel housing and steam trap or sterile water filtered down to 0.2 micron using PES membrane cartridges.

9. Molding and pressing

Low-pressure steam is used to heat cheese molding and pressing equipment at a precise temperature. Steam filtration helps protect this last stage of processing.

Filtration option: Culinary steam produced using 5-micron absolute rated steam elements in a stainless steel housing and steam trap.

10, 11 and 12. Compressed air

The contaminants most prevalent in compressed air systems are water and oil, which make an ideal organic diet for microorganisms. Keeping the air dry will slow the propagation of microorganisms and prevent condensation issues in the air system. Additional drying steps are advisable beyond the refrigerated dryer, which typically only reduces the dew point to 40ºF. Point-of-use desiccant dryers that dry the air to -40ºF contribute to a moisture-free system.

Filtration option: From the compressor, placing a cyclone separator, series of 5 micron nominal to 1 micron absolute coalescing filters, a desiccant dryer and an absolute rated 0.2-micron sterile air filter in a sanitary designed stainless steel housing.

Recent developments in filtration technology

Beyond micron and efficiency ratings, performance factors that drive cost-of-ownership for filtration systems include:

- Depth-loading capacity (retention)

- Number of sterilization cycles tolerated (filter life)

- Flow rates, which determine energy costs

Advances in technology can help lower overall filtration costs. The following are three developments worth noting:

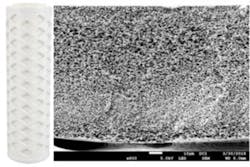

Pleated specialty media cartridge filters — Traditional melt-blown filters have porous fiberglass media blown into a solid tube. Pleated cartridge filters utilize coated, spunbond media densely folded into a cylindrical cage. This configuration creates twice the surface area and depth-loading capacity of a melt-blown counterpart. Better and longer capture performance can potentially offset the higher initial cost of a pleated filter. (See Figure 4.)

Figure 4. Pleated cartridge filters

High-volume liquid filters — Major beverage companies in Europe and the U.S. worked for two years with microfiltration engineers on a liquid filter designed specifically for high production demands. The new elements were introduced in 2016 by Donaldson Company. Within a standard 2.75-inch-diameter housing, the element has 20 percent more media (polyether sulfone) than comparable filters and asymmetrical pores that provide the ideal cutoff range for sterilization while improving flow capacity. Its housing has triangular ribbing — similar to a support bridge — to resist force during installation, operation and sterilization. Together, the modifications help deliver higher throughput and longer filter life. (See Figure 5.)

Figure 5. Liquid filters

Sterile air filters for extreme conditions — New final membrane filters for sterile air can withstand 150 to 200 vapor phase hydrogen peroxide (VPHP) or ozone sterilization cycles — a significant increase over elements that commonly last 50 to 100 cycles.

Introduced in early 2018, Donaldson’s sterile air filters feature elements that capture bacteria, viruses and particles down to 3 nanometers, while remaining temperature-resistant up to 392ºF. The elements also dry quickly, helping to minimize downtime necessary for cleaning. (See Figure 6.)

Figure 6. Sterile air filters

Conclusion

Process owners are responsible for identifying and managing critical filtration within their processes. It can be beneficial to work with an industrial food safety consultant who can audit a process and recommend modifications. Having a plan and qualified filtration partner can help significantly manage risks and costs in a food-safety initiative.

REFERENCES

- Guidance on the FDA Food Safety Modernization Act (FSMA) https://www.fda.gov/Food/GuidanceRegulation/FSMA/

- Regulatory and Best Practices Overview of standards related to filtration of air, steam, and liquid in food applications, compiled by Donaldson Company Inc. https://www.donaldson.com/en/process/literature/096777.pdf

- 3-A Sanitary Standards Institute, http://www.3-a.org/3-A-Symbol/Buyer-Beware-False-or-Misleading-Claim.

Chris Lehmann is the North American product manager for the Process Filtration division of Donaldson Company Inc. He has more than 10 years of manufacturing and industrial processes experience, with knowledge and expertise in the application of filtration products.