In the world of oil extraction, there is both sweet and sour crude. Sweet oil usually contains less than 0.5 percent sulfur, and oil classified as sour contains higher levels of sulfur, which is typically in the form of foul-smelling hydrogen sulfide (H2S) gas. Because hydrogen sulfide is toxic and highly corrosive, sour crude is more expensive to refine and requires the use of corrosion-resistant topsides equipment, costly sulfate removal plants (SRPs) and chemical dosing regimes.

Sulfide is often found to occur naturally in oil due to the presence of native geological sulfide — hence, whether as a result of geology or geochemistry, sour crude is common across several oil-producing regions of the world. Yet, while sour crude requires expensive treatments, it is important to note that sweet crude (having a very low H2S content) is beneficial to the oil well environment and the processing equipment due to the reduced risk of damage to asset metallurgy and lower chemical treatment costs.

With the cost of oilfield reservoir souring control rumored to consume as much as one-third of typical production budgets, it is essential for operators to accurately assess whether souring is likely to take place in their fields and, if so, to understand the degree of souring in order to treat it effectively and economically.

Regular pressure/temperature monitoring of pressurized bioreactor suite

Microbiological oilfield reservoir souring

Successfully extracting oil throughout the life of a reservoir, however, requires additional downhole pressure. And it is the process of pumping water (often seawater, containing sulfate) into reservoirs — to maintain pressure during secondary recovery — that can introduce sulfate-reducing bacteria into what would otherwise be a sweet crude oil environment. The result is a process called microbiological oilfield reservoir souring, where the introduction of seawater, which is used to ensure the crude continues to flow throughout operation, provides the additional sulfate and microbiology necessary for increased concentrations of H2S when downhole conditions are optimal for microbial growth.

Occurring naturally in seawater, the microbial life-forms, which can cause crude oil to sour, use the sulfate present in both the injected seawater and the reservoir, producing hydrogen sulfide and potentially leading to reservoir souring of a greater or lesser degree. To thrive, these bacteria, which are not too dissimilar from those found in the sediments of lakes and streams, require water, sulfate (which they chemically reduce and convert to sulfide), an anaerobic (oxygen-free) environment and carbon as a source of energy, typically the crude oil itself. With all those ingredients in place, a water pH of 4 to 9, a temperature of 10°C to 80°C and a pressure range from 1 psig to 10,000 psig are essentially all that is required for microbial sulfate-reducing bacteria to flourish.

Oilfield reservoir souring can take place when increasing concentrations of hydrogen sulfide are observed in crude oil production. However, as it can take several years of secondary recovery operations and resulting microbial activity before any increased souring is detected in fluid output, the real challenge for operators is to identify a souring risk early enough to ensure that it can be treated cost-effectively — either through the use of injection chemistries such as nitrates and biocides or through end-of-pipe scavenger solutions.

Until recently, investigations into whether or not an oilfield would sour involved the use of simple sand, oil and seawater bottle tests, or upflow sand packs that were subjected to atmospheric pressure. Such tests, however, could not be used to draw accurate comparisons with actual field conditions and biological activity, primarily as they were unable to replicate the pressures or temperatures found downhole.

Oilfield chemistry evaluation in atmospheric bottle test study

Microbiological oilfield souring research program

In 2003, to investigate the effects of pressure and temperature on oilfield microbiology, U.K.-based oilfield services company, Rawwater, began operating a number of pressurized bioreactors — specially designed corrosion-resistant columns that could be subjected to high pressures and high temperatures. Oil majors and chemical service companies showed interest in the further development of Rawwater’s pressurized bioreactors as a research tool. Their interest led to the Seriatim series of work into oilfield souring, with approximately $10 million in funding set aside for the company to establish a pressurized bioreactor data set.

In 2006, Rawwater started a pressurized bioreactor study program for the oil industry. Using bioreactors containing sand (to mimic downhole mineralogy), seawater and crude oil (initially sourced from fields in the North Sea) and then inoculated with oilfield bacteria, the company began monitoring microbial growth at the same temperatures and pressures found downhole to determine the efficacy of various injection chemistries for souring control.

Rawwater has been subculturing oilfield bacteria strains for more than 30 years and now operates an advanced facility to study and evaluate microbiological souring in simulated reservoir conditions. At least 45 pressurized bioreactor columns, ranging from 25 centimeters to 4 meters in length, are in daily operation at the organization’s U.K.-based research facility. By 2018, the company had accrued the equivalent of 400 years’ worth of pressurized oilfield souring data — a growing data set containing information relevant to reservoirs across the globe.

Testing conditions at Rawwater’s U.K.-based laboratories range from atmospheric pressure to 12,000 psig, with temperatures ranging from 5°C to just below the boiling point of water. Souring studies, including large-scale research and development (R&D) joint industry projects (JIPs) and single-client studies, have lasted from a matter of weeks to a number of years to monitor the rate of souring and have been operated using crude oil and seawater samples from major oilfields globally. The data generated by Rawwater covered a range of operating conditions, including accurate chemistries at pressure and temperature.

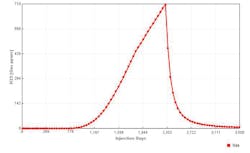

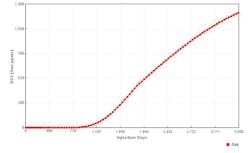

Souring forecasting profile of sour oilfield A

Souring forecasting profile of sour oilfield B

Drilling down into the data

To assist operators in establishing if, when and to what extent their oilfields will sour, data from Rawwater’s pressurized bioreactor studies is entered into the organization’s DynamicTVS (Thermal Viability Shell) predictive oilfield souring tool. The software modeling program uses operational, planning and survey data taken from all phases of oil production under any temperature and pressure conditions to predict hydrogen sulfide production over the lifetime of a reservoir.

Developed over many years, the software can forecast a reservoir’s propensity to sour in advance of well completion — invaluable information to operators. Once a base profile for souring is established, a real-time sensitivities processor is used to examine the effects of changes across multiple parameters, for example, modifying inputs such as injection temperature, injection sulfate concentration and time to breakthrough of injected water. Using the program, Rawwater has conducted a large number of reservoir forecasts on fields in the North Sea, Gulf of Mexico, Africa and the Middle East.

The DynamicTVS model describes the cooling of an oil reservoir due to water-flooding, the opportunity for growth of sulfate-reducing microorganisms (SRM) in the cooled zone, the transport of the hydrogen sulfide produced by the SRM to the producer and the downhole and topsides partitioning of the sulfide at specified pressures and temperatures.

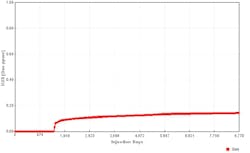

Souring forecasting profile of a sweet oilfield

Cost-saving reservoir souring forecasts

Believing that platforms previously set up for sweet oil service would be unable to receive sour fluids once breakthrough of injected water is observed at the producer, topside operators may assume that the installation of a costly sulfate removal plant (SRP) would be necessary for reservoir souring control. However, all oilfields have different souring propensities, so accurate reservoir souring forecasts are essential for optimized, cost-effective treatment strategies.

For example, Rawwater recently demonstrated to a West African operator that the installation of an SRP was not required for souring control on a specific asset — saving the operator approximately $100 million. By applying its souring forecasting model to the reservoir data set, Rawwater showed that the pressure and temperature conditions found within the reservoir were too extreme to support microbiological growth and therefore prohibited sulfide production downhole.

A 12-month pressurized bioreactor study using crude oil samples from the reservoir then followed, which supported the findings of the souring forecast. As a result, it was determined that no souring control treatment was required for the downhole formation. However, low-cost monitoring and control measures would be required to mitigate any deleterious microbial activity, as well as subsequent microbiologically influenced corrosion, within the topside production facilities.