Texas A&M researcher develops method to reduce energy cost of chemical separation

Dr. Hae-Kwon Jeong, associate professor in the Artie McFerrin Department of Chemical Engineering at Texas A&M University, developed a method to separate light olefins – such as ethylene and propylene that are used in packaging, plastic processing and textile manufacturing – from paraffins such as ethane and propane.

Jeong’s research focused on the use of membrane-based separations. Membrane-based separations act much the same as colanders or strainers; a mixture flows through the membrane that allows the smaller molecules through, while excluding the larger molecules. Light olefins and paraffins present a challenge as the size differences between the molecules are around .3 Ångströms (around 0.000000003 centimeters). Polymers are not selective enough to be a useful membrane for this process.

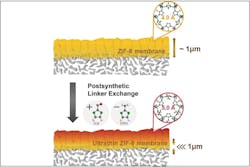

Jeong’s research utilizes metal-organic frameworks (MOFs) as the membrane material, especially Zeolitic-imidazolate frameworks (ZIF), which are composed of metal ions (usually Zn2+ or Co2+) and imidazole-derived organic linkers. Jeong has already shown that ZIF-8 membranes (composed of zinc and 2-methylimidazole) are effective at separating propylene and propane. However, ZIF-8 membranes are relatively expensive to produce, and a significant improvement to their productivity – essentially the speed with which the molecules are filtered – is required for them have any practical applications. There are two ways increase the productivity of the membrane; reduce the membrane thickness and/or increase the area per volume of the membrane.

Jeong developed a method to drastically reduce the effective size of the ZIF-8 membrane, detailed in a paper published in Angewandte Chemie. Rather than using a membrane composed wholly of ZIF-8, he replaced the top layer of the membrane with ZIF-90. The aperture of ZIF-90 is slightly larger than that of ZIF-8, but they both share the same structure. Therefore, by adding the top layer of ZIF-90, Jeong was able to reduce the effective thickness of the ZIF-8 membrane, which increased the propylene permeance by about four times with little to no loss in its separation effectiveness. This drastically improves the productivity of ZIF-8 membranes and opens the door for practical applications.

Applied Membranes receives presidential award for exports

U.S. Secretary of Commerce Wilbur Ross presented Applied Membranes Inc. with the President’s "E" Award for Exports at a ceremony in Washington, D.C., on May 21. The President’s "E" Award recognizes U.S. entities that make a significant contribution to the expansion of U.S. exports. Applied Membranes Inc. manufactures reverse osmosis systems, reverse osmosis membranes and water filtration components under the AMI label.

"Applied Membranes has demonstrated a sustained commitment to export expansion," said Secretary Ross in his congratulatory letter to the company announcing its selection. "The ‘E’ Awards Committee was very impressed with Applied Membranes’ more than 500 percent growth in exports over the past four years, which supported a 20 percent increase in employment. The company’s development of a domestic project to use as a prototype for a project in the Middle East was also particularly notable. Applied Membranes’ achievements have undoubtedly contributed to national export expansion efforts that support the U.S. economy and create American jobs."

Assured Automation announces relocation and expansion

To handle expansion of personnel and projected inventory, Assured Automation — a supplier of automated valves, quarter turn electric and pneumatic valve actuators, digital flowmeters, mechanical flowmeters and valve accessories — will move into a new facility at 263 Cox St. in Roselle, New Jersey.

“The reasons this current move was important for us were both practical and aesthetic," said Mike O’Neill, vice president of Assured Automation. "We were looking for a more modernized facility with enhanced finishes but we also needed a larger space overall. We’ve greatly expanded our warehouse and production areas, and we now have a dedicated military project testing area, which is ITAR (International Traffic in Arms Regulations) regulations compliant.”