Chemical manufacturer improves quality of source water

An Indian chemical manufacturer is using nearby river water as its water source for its manufacturing process. Due to the poor water quality in the river, and especially following rain events, the existing water treatment system that was made up of clarifiers and media filters did not function properly and did not deliver the required water quality and quantity.

As a result, the plant’s engineering team was looking to install a solids separation step that would allow for continuous high-quality water supply to enter the plant regardless of the flocculating water quality, even under the high water turbidity and total suspended solids (TSS) concentrations that are common in the monsoon season. The plant had limited space available for new installation, so a solution with minimal footprint was required.

Traditionally, most solids separation processes are dependent on the density difference between the water and the particles. Particles might have higher density than water and will settle in a settling basin or will have lower density than water and will float and be skimmed from the surface of the water.

Since many particles have density that is very close to water, in order to achieve high-efficiency solids separation, separation by density difference needs to work at very low velocity (0.5–1 m/hr), requiring a large footprint and associated costs. Another alternative is to float the particles using dissolved air flotation (DAF), but that requires a high capital and energy investment.

While processes that remove particles using centrifugal forces do exist in the market as an alternative to separation by density difference (e.g., hydrocyclone), they are very limited in particle size separation (larger than 70 µm) and particle density (larger than 1.9 g/cc). Therefore, they are mainly used for sand separation. Further, the shear forces created in the hydrocyclone will prevent the use of coagulation and flocculation processes since flocs will be broken, thus rendering the process ineffective.

The recently developed hydrodynamic separator from AquaHD is free from the limitations of conventional solids separation processes. The hydrodynamic separator works by creating centripetal hydrodynamic forces to separate particles under low pressure (1 bar). In the hydrodynamic separator, the water is flowing through a dedicated circular structure. The water’s path through this structure allows the creation of high centrifugal forces (6–8 G) under low pressure. The unique geometry and flow patterns of the liquid inside the hydrodynamic separator allows for the creation of laminar flow.

The configuration of the separator was developed using a complex mathematical model that creates flow structure, causing high-level and efficient separation of the suspended particles. Unlike other traditional solutions, the hydrodynamic separator removes a wide range of organic and inorganic suspended solids as small as 2 microns from water with dirt load of up to 4,000 PPM of TSS.

In April 2019, the hydrodynamic separator was installed at the Indian site to treat a flow of 200 m3/hr. One of the main challenges here was the limited space available for installation of a new water treatment system. Due to the existing equipment on site, mainly an emergency clarifier and a cooling tower, and the associated pipes, equipment, concrete footing, etc., the total available space for the hydrodynamic separator was 5x5 meters. However, because of the small footprint and modularity of the hydrodynamic separator, AquaHD was able to design a solution that met the site’s specific needs and simplified the installation process.

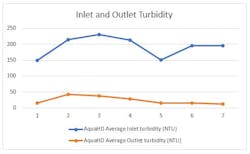

The hydrodynamic separator consistently achieved 80–90 percent turbidity reduction, regardless of the inlet conditions (see Fig. 1). It is suitable for any type of water treatment with high turbidity (larger than 50 NTU) or that requires high solids removal. The separator has also proven to be very effective in removal of small particles (e.g., algae) from water. IWW