Metso starts full-scale testing of filter for tailings dewatering in Brazil

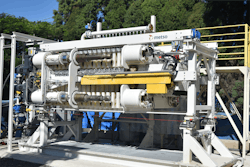

SOROCABA, Brazil — In 2019, Metso launched Tailings Management Solutions (TMS), its response to the global challenge of managing mining tailings efficiently. Metso sees the dewatering of waste as the future of mining, allowing the removal of the water and its reuse in the plant itself or restoration to nature. The latest development took place at Metso's facilities in Sorocaba, Brazil, where the first full-scale tests of the Metso VPX™ filter started in March 2020.

The unit will process ore samples sent by several mining companies from Brazil and Latin America. "This is not a laboratory test, but filtration in industrial scale conditions using VPX technology, which has the capacity to process high volumes of ores", says Rodrigo Gouveia, Vice President, Tailings Management Systems, Metso “Tailings dewatering is technically and economically a viable option for today and the future. Dry stacking is widely acknowledged to be the safest, most sustainable option for tailings storage. We see that there is a strong demand for short- and medium-term technical solutions.”

Fausto Rezende, Metso’s mining equipment sales director and in charge of TMS in Brazil, highlights that there is another potential aspect to the adoption of tailings management: legacy dams. "We can develop projects for the dredging and concentration of the tailings and in many cases, it is possible that this operation is more economically viable than virgin ore", he concludes.

Metso Tailings Management Solutions

With its strong expertise in dewatering solutions, Metso moves the mining industry towards dry tailings and addresses the closure of legacy dams with socially responsible and economically proven solutions. Depending on each mining application and needs, Metso carries out engineering and determines the specifications for the most suitable dewatering technology, including from lamellar thickeners, hydrocyclones and filters to tailings stackers, through pumping solutions and conveyor belts. Visit Metso’s website (metso.com) to learn more about Metso VPX™ filter and Tailings management.

About Metso

Metso is a world-leading industrial company offering equipment and services for the sustainable processing and flow of natural resources in the mining, aggregates, recycling and process industries. With our unique knowledge and innovative solutions, we help our customers improve their operational efficiency, reduce risks and increase profitability. Metso is listed on the Nasdaq Helsinki in Finland and had sales of about EUR 3.6 billion in 2019. Metso employs over 15,000 people in more than 50 countries.