The Port of San Diego (Port) is currently implementing its Tenth Avenue Marine Terminal (TAMT) Redevelopment Plan and associated Environmental Impact Report (EIR), which includes a variety of infrastructure investments that will be undertaken over several years to accommodate an increase of the terminal’s capabilities and capacity while concurrently minimizing the environmental impacts from terminal operations.

The purpose of the overall modernization concept is to increase terminal capacity, create jobs, provide expanded stormwater treatment, and provide greater flexibility to meet current and future market conditions. Furthermore, by implementing project-specific technology improvements and factoring in regulations, environmental impacts from maritime activity at the terminal is minimized.

In 2015, the Port competed for and was awarded a $10 million Transportation Investment Generating Economic Recovery (TIGER) grant from the U.S. Department of Transportation to help fund the project. The Port has matched the grant with a $14 million contribution. This strategic funding approach allowed the Port to leverage the grant opportunity for innovative stormwater treatment as part of terminal modernization.

The initial phase of the TAMT Redevelopment Plan is called the Tenth Avenue Marine Terminal Modernization Project – TIGER Phase 1 – Stormwater Treatment System. This phase consisted of demolishing two large transit shed structures, relocating maritime staff offices, installation of permanent stormwater Best Management Practices (BMPs), and asphalt replacement along the southern berths of TAMT.

The improvements of this initial phase required that 8.8 acres of disturbed area comply with the Port’s BMP Design Manual, following San Diego Regional MS4 Permit requirements to capture and treat the project’s runoff. The finished grade would be a full replacement of concrete and asphalt pavement to expand the terminal’s staging and layout areas.

The Port saw this as an opportunity to integrate additional stormwater capture and treatment into the project and treat a much greater drainage area than the 8.8 acres obligated under Port BMP Design Manual requirements.

The project team assembled workshops to understand how to strategically capture a larger drainage area and treat stormwater before it is discharged into San Diego Bay. A compact treatment concept using the Modular Wetlands System Linear designed by Bio Clean was then designed to treat 41.4 acres of the 96-acre TAMT: 40.3 acres drain to the specific project site, and 1.1 acres drain to another Modular Wetlands System Linear that treats runoff from new office structures on site. The project treats almost half of TAMT.

Maximizing Construction Efficiencies

The BMP construction was integrated into demolition of the transit sheds, thereby limiting impact to terminal operations and maximizing construction efficiency. Because of the size of this BMP, combining its construction with the transit shed demolition was the only opportunity to implement this ambitious and extensive water quality improvement on such a busy facility.

Existing BMPs were also leveraged in design. For example, storm drain inlet filters are installed across the drainage area to limit trash and debris entering the Modular Wetlands System Linear and therefore minimizing the need for maintenance of the units.

Design Specifics of the Project

The type of treatment units selected for the project were Modular Wetlands System Linears; however, they required a custom design and modification to the operational filtration methods to overcome specific site constraints. As a result, the Modular Wetlands Systems were designed with a flow-based (as opposed to volume-based) approach to remove the requirement for a cistern, which would have been cost prohibitive. Also, with high groundwater at the site, buoyancy of the Modular Wetlands System Linear was a concern, so larger structures were used acting as their own buoyancy collars.

The project installed 11 large treatment units in series. Flows from the existing 36-inch reinforced concrete pipe (RCP) storm drain line are diverted by way of a broad-crested weir into a new 18-inch PVC pipe storm drain system parallel to the 36-inch RCP storm drain line. The new 18-inch PVC storm drain system routes flows into the alignment of 11 treatment units using 8-inch PVC laterals to each. The Modular Wetlands System Linear treatment units have outlet-limiting manifold structures to throttle the flows through the units and to allow for enhanced treatment of pollutants within the media mix.

The outflow at each treatment unit is collected into 24-inch PVC pipe segments connected to the downstream side of the treatment units. The flows are then routed to a cleanout box that leads back to the existing 36-inch RCP storm drain line.

Since tidal influences were a major constraint with the operation of the existing 36-inch RCP storm drain line and the treatment units, a tidal check valve was placed to prevent tidal flows from entering the existing and proposed system.

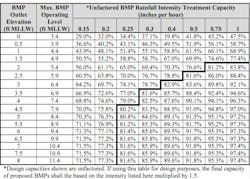

A continuous simulation model was developed to account for tidal inundation of the BMPs. This continuous simulation indicated that 27.3 acres of full treatment could be expected over the life of the BMP, but partial treatment would be seen even during storm events that occur at tides below 5.15 feet Mean Lower Low Water (MLLW) and full capacity treatment for storms that occur at tides below 1.7 feet MLLW. The simulation was run for a period of almost 14 years (July 1, 2003 through June 10, 2017).

Table 1 shows the results from the continuous simulation model. It indicates that as tidally influenced BMPs are proposed at lower elevations, the capacities of these BMPs must be increased in order to capture and treat 80 percent of the average annual runoff. The thick line represents the approximate delineation between the ranges of acceptable and unacceptable BMP design capacities.

Each Modular Wetlands System Linear is 21.5 feet long by 11.5 feet wide by 8.7 feet tall, for a total footprint area of 2,700 square feet, and each unit is designed to treat up to 0.69 cubic feet per second (cfs). The combined series of the treatment units allows for 7.59 cfs to be treated at the site. The Port is obligated to treat for up to 8.8 acres, or 2.51 cfs, which is the total area of the project.

Following the Port’s BMP Design Manual, the worksheet to size flow-through treatment control BMP facilities is based on determining the maximum flow rate of runoff produced from a rainfall intensity of 0.2 inch of rainfall per hour. The rainfall intensity is inserted into the rational formula equation of Q=CIA. At the project site, the obligated area treatment design flow rate was determined to be 1.67 cfs and a factor of 1.5 was applied to the design flow rate. This results in an obligated design flow rate of 2.51 cfs. The 11 treatment units are designed to treat up to 7.59 cfs, resulting in a credit of up to 5.08 cfs to be used by the Port to implement other improvements at the terminal.

Effective Removal of Priority Pollutants

Priority pollutants of concern at TAMT include metals and total suspended sediment (TSS). These priority pollutants of concern were determined based on years of water quality monitoring at TAMT and a knowledge of terminal operations.

Bio Clean’s Modular Wetlands System Linear has achieved the Technology Assessment Protocol – Ecology (TAPE) certification from the State of Washington Department of Ecology for plant less systems and therefore meets Port BMP Design Manual requirements.

Based upon laboratory testing, the Modular Wetlands System Linear has the potential pollution reduction efficiencies as outlined in Table 2.

Conclusion

The Tenth Avenue Marine Terminal Modernization Project – TIGER Phase 1 – Stormwater Treatment System project is exemplary for many reasons and was developed with a team approach to maximize stormwater capture on the marine terminal. This BMP was designed and constructed to maximize treatment while maintaining efficient, cost-effective implementation. It showcases the Port of San Diego’s commitment to innovative BMP design and implementation, and environmental stewardship of San Diego Bay. WT

About the Author

Christian Braun is a senior environmental specialist in the Port of San Diego’s Environmental Protection Department with over 20 years of experience in stormwater and water quality management.

About the Author

Christian Braun

Christian Braun is a senior environmental specialist in the Port of San Diego’s Environmental Protection Department with over 20 years of experience in stormwater and water quality management.