Bioaugmentation for Reduction of Lagoon and Pond Sludge

Many industrial plants use lagoons and ponds as part of their wastewater treatment strategy. These ponds can be used as primary, secondary or tertiary treatment. The wastewater can comprise both inorganic and organic suspended and dissolved solids, as well as bacteria. With enough residence time in these impoundments, suspended solids will settle and gradually build up. In addition, the bacterial activity will degrade many organic compounds producing biological growth, with the resultant biomass often settling to the bottom of non-aerated ponds.

Wastewater lagoons have inherent advantages and disadvantages compared to an engineered wastewater treatment plant with its equipment in place to aid in the settling of solids and the subsequent removal and dewatering of that sludge.

Periodic dredging of these solids to maintain proper hydraulic residence time to meet National Pollutant Discharge Elimination System (NPDES) permit requirements is often needed. Dredging operations may need to be done annually or every few years, based the incoming solids loading to the lagoon or pond system.

Dredging costs are often very high and must be budgeted for years in advance. The planning is complicated by the need to ensure that manufacturing and production are not impacted by the inability to handle wastewater and settled solids. Final disposal of solids is often offsite, and costs can include chemical conditioning, mechanical dewatering, contractor fees, and transportation to approved landfills or land application, depending on the local regulations and sludge characteristics.

An Alternative Approach

SUEZ has a unique bioaugmentation product, BioPlus* BA3903, that is added to impounded sludge lagoons and treatment ponds containing organic solids that are amenable to biodegradation. Harnessing nature’s sanitation workers (bacteria) to improve wastewater treatment efficiency is the basis for the successful degradation of industrial organic compounds in many types of secondary treatment systems, including ponds and lagoons. Bioaugmentation is the artificial enhancement of this process by the introduction of additional microorganisms and/or nutrients to the treatment system. Bioaugmentation can speed up the naturally occurring but slow degradation from the indigenous bacterial population.

This new product is packaged into small, dense “sticks” or spikes, and the weight of the product allows it to sink rapidly into the selected areas to deliver the bacteria, enzymes, and nutrients directly to the pond sediment layer. As the stick gradually dissolves, the released components are delivered to the solids layer instead of the overlying water phase. Over time organic solids are gradually degraded by the bacteria.

Depending on the application, product addition can be at higher dosages in problem areas for faster sludge reduction. Existing sites using this treatment have also seen an improvement in the bio floc formed after treatment, which results in larger and denser floc particles.

Additional benefits to sludge management include improved compaction of the sludge due to the formation of denser floc particles. This denser floc contains less water, allowing for greater compaction of sludge. Enzymes help degrade substances that hold the decaying biomass in the sludge together. With the addition of these beneficial organisms, further completion of the overall degradation of the decaying biomass and organics is improved.

The overall effect of the two processes is a reduced sludge volume and concomitantly increased pond water volume, which translates into increased treatment capacity and reduced need for dredging.

Properly designed and engineered treatment protocols, as well as monitoring and documentation of sludge reduction, improves overall performance. The use of this product has been shown to extend the time required for periodic dredging of solids and reduction of the volume of solids in situ throughout treatment. Two case examples are provided to demonstrate the successful application of this product.

Case Study: Oil Refinery

A refinery was faced with solids accumulation in its final effluent treatment pond, which reduced pond capacity by nearly half over time. Typically, a refinery, like many industries, must pay a contractor to dredge the ponds every few years at a cost often in the millions.

BioPlus BA3903 was selected to evaluate efficacy in the sludge reduction in this system. A small polishing pond was chosen for a trial in this case.

A hydrographic pond survey was conducted to measure the actual sludge depth and solids accumulation. The product was then applied across the area to be treated following dosage recommendations. A boat was used to allow better access to the pond, improving treatment coverage. A second smaller maintenance dosage was applied 30 days later, and a third, 30 days after that. After another 30 days, the hydrographic survey was repeated to determine the sludge reduction impact.

The initial pond survey showed that 2,094 cubic yards (1,600 m3) of sludge existed in the pond. Three months later, the post-treatment survey showed that the sludge quantity had been reduced to 1,573 cubic yards (1,203 m3), representing a reduction of 521 yd3, or 25 percent.

To fully understand the causes of this solids reduction, a mass balance of suspended solids across the ponds was conducted during the trial. By closely monitoring the total suspended solids (TSS) entering and leaving the pond in the wastewater, it was shown that there was a net loss of 7 to 8 tons of TSS in the pond effluent. Old data showed that this was a trend in previous summers (similar time frame to this trial). The volume of sludge reduction due to the BioPlus treatment was calculated by subtracting the net TSS loss in the effluent from the overall sludge reduction. The 521 yd3 (398 m3) is equivalent to about 478 metric tons of sludge. The net reduction from biodegradation was about 470 metric tons (518 U.S. tons), or 24 percent. The return on chemical investment (ROI) to this refinery was at least 565 percent.

Case Study: Food Manufacturing Facility

At a food industry facility with a 65-million-gallon treated water lagoon was facing solids dredging to improve pond capacity. The pond had lost 69 percent of its capacity due to impounded solids, with solids built up also in an adjacent receiving pond. This condition required bypassing influent to another pond before returning water to the receiving pond due to mechanical issues, leading to complexity in managing wastewater flow through the system.

An evaluation of one lagoon was conducted to test the efficacy of BA3903 on the organic solids present, using a hydrographic survey to establish the existing sludge depth and thus volume, sludge composition, and to identify atrial area or areas to evaluate the product initially. The site’s management decided to evaluate the use of BA3903 before committing to a pond dredging operation.

After a site audit, the pond sludge was identified as high in organic composition, a perfect condition to consider the use of BA3903. A trial was started on one area of the pond to determine removal efficacy, and a plan to evaluate a section of the lagoon was established, with measurements made to determine the volume of sludge in that test area.

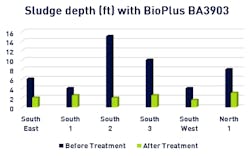

The product was applied at recommended dosages in a test area where 15 feet of sludge was initially measured. Ten days later, the second application of the product was added after measurements showed a reduction of sludge depth from 15 to 2 feet in one area and 8 feet to 2½ feet in an adjacent area of the lagoon. Several locations within the lagoon were monitored with successful sludge reduction, as shown in Figure 1.

After the results were determined, the evaluation was deemed successful by the plant manager. Further treatment is planned elsewhere in the pond system where sludge buildup has occurred over time. Since the trial treatment, no area has been dredged, and further monitoring to identify critical areas of the lagoon will be carried out before additional treatment.

To stay ahead of conditions where inlet flow brings in organic solids, it was recommended to continue a maintenance treatment program to proactively control the buildup of sludge instead of waiting for it to accumulate. Routine performance monitoring will be implemented to show continued treatment efficacy.

Dredging costs of over $700,000 in contractor fees would have been spent if BioPlus BA3903 was not used, and a savings of over $625,000 will be realized with the use of this product at this site.

Summary

In summary, this unique bioaugmentation approach can provide wastewater plant operations with multiple benefits, including: reduced dredging frequency; reduced volume of sludge to be removed; increased operating lagoon volume and thus enhanced wastewater treatment capacity; increased retention time and reduced short-circuiting; and no hazardous residuals to handle. WT

*Trademark of SUEZ; may be registered in one or more countries.

About the Authors

Larry Smith is a senior customer applications engineer and Peter Norman is a senior product applications engineer, both with SUEZ – Water Technologies & Solutions.

About the Author

Larry Smith

Sr. Customer Applications Engineer, SUEZ – Water Technologies & Solutions

Larry Smith is a senior customer applications engineer with SUEZ – Water Technologies & Solutions.

Peter Norman

Sr. Product Applications Engineer, SUEZ – Water Technologies & Solutions

Peter Norman is a senior product applications engineer with SUEZ – Water Technologies & Solutions.