Understanding desalination: The well that won’t run dry

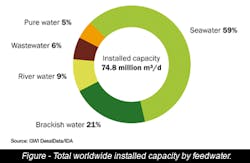

Desalination, also called "desalinization" and "desalting," has become an integral and often critical part of water management strategies in countries around the world. With total global installed capacity now exceeding 75 million cubic meters per day (m3/d), it is the source for some, or all, the daily water needs of an estimated 300 million people around the world.

From smaller reverse osmosis units that treat residential water systems to huge plants like Shoaiba 3 in Saudi Arabia that produces 880,000 m3/d, the use of desalination has experienced tremendous and continuing expansion due to such factors as population and economic growth, pollution and degradation of traditional water supplies and the impacts of climate change. There are now more than 16,000 desalination plants around the world, with a total of 632 new plants added from mid 2011 to August 2012 alone. Since 2008, global online capacity has increased by 57 percent, and in 2002, the total online capacity was less than half of what it is today.

What are the technologies being used today, and how have they advanced over the years? What are some of the emerging technologies that will impact this industry? What are some of the challenges that it faces today? Let’s explore some of those topics.

Evolution of desalination technologies

Desalination is the process of removing dissolved salts from water, thus producing fresh water from seawater or brackish water. People have been desalinating water for centuries. In fact, one of the first mentions of desalination was made by Aristotle, who wrote of seawater distillation in 320 B.C.

In the post war years, scientists began studying osmotic processes to desalinate water. The first reported use of the term "reverse osmosis" — now a popular desalination technology — appeared in the U.S. Department of Interior’s Office of Saline Water 1955 annual report. Development continued, and in the 1970s, commercial membrane processes, such as reverse osmosis (RO) and electrodialysis (ED), began to be used more extensively. Since ED could desalt brackish water more economically than distillation, more interest was focused on using desalination as a way to provide water for municipalities with limited fresh water supplies and the availability of brackish water sources.

By the 1980s desalination technology became a fully commercial enterprise, and by the 1990s the use of desalination technologies for municipal water supplies was commonplace.

Today, the major desalination processes employ membrane and thermal technologies. According to data published by the International Desalination Association (IDA) and Global Water Intelligence (GWI), RO now accounts for 63 percent of installed capacity, followed by two thermal processes — multi-stage flash (MSF) at 23 percent and multi-effect distillation (MED) at 8 percent. Electrodialysis (ED) follows at 3 percent, and hybrid processes at 1 percent. Other processes account for 2 percent.

Membrane desalination technologies include RO, ED/electrodialysis-reversal (EDR) and nanofiltration (NF).

RO involves separating water from dissolved salts by passing feedwater through a semi-permeable membrane at a pressure greater than the osmotic pressure caused by the dissolved salts. Steps in the RO process include:

• Pretreatment of the feedwater via mechanical and chemical means to remove suspended solids, adjust the pH and control scaling and fouling

• Use of high pressure pumps to increase the feed pressure before the raw water is delivered to the membranes

• Membrane separation of the dissolved salts rejected by RO membranes and the product stream diffusion through the membranes

• Degasification (if needed), pH adjustment and stability enhancement of the product water before it is transferred to the distribution system.

RO is the most prevalent technology used outside the Middle East region for purposes of desalinating water. Ongoing advances in this technology have produced membranes with improved performance characteristics and greater productivity and energy recovery devices that result in lower pumping energy requirements.

ED/EDR is the separation of a solution’s ionic components through the use of semi-permeable, ion-selective membranes operating in a direct current (DC) electric field. ED was originally developed as a less expensive alternative to distillation as a method to desalinate brackish water.

Another desalting membrane process is NF, which rejects solutes larger than approximately one nanometer in size. Nanofiltration is used primarily in water softening applications for removal of hardness ions. It has replaced lime softening in many municipal projects around the world and also removes color sometimes found in ground and surface water supplies. Nanofiltration has also found a niche application in the offshore oil and gas industry for purposes of treating injection water for water flooding of reservoirs in enhanced oil recovery processes.

The two major thermal desalination technologies are: Multi-stage Flash (MSF) and Multiple Effect Distillation (MED). Multi-stage flash evaporation is a desalination process where a stream of hot brine flows through the bottom of chambers, or stages, each operating at a successively lower pressure and temperature, and a proportion of it flashes into steam and is then condensed on the tubes preheating the brine. MSF is also known as Flash Distillation.

Multiple effect distillation (MED) is a thin film evaporation process in which the vapor formed in one chamber, or effect, condenses in the next one, providing a heat source for further evaporation. Thermal processes are widely used for seawater desalination in the Middle East, although RO is gaining some acceptance and some "hybrid" plants in the region are now being built or retrofitted to employ both thermal and membrane technologies.

It should also be noted that many desalination facilities, particularly in the Middle East and North Africa region, have been constructed as co-generation facilities as dual purpose plants, which simultaneously produce both electrical power and desalinated water within the same complex. Most of the thermal desalination distillation processes are normally designed to take advantage of a co-generation situation.

Emerging technologies

For many years the desalination industry has been focused on reducing energy requirements. This effort has proven to be quite successful. Over the past two decades, energy consumption has been reduced by more than 50 percent. Work continues to lower energy requirements even further. In 2012, the International Desalination Association formed a global Energy Task Force that challenged the industry to achieve a 20 percent reduction in energy consumption in all major seawater desalination processes by 2015.

However, bringing technological advances from the R&D phase into commercialization is one of the challenges that the desalination industry is facing. In a recent interview, Dr. Corrado Sommariva, president of the International Desalination Association, addressed this challenge. "It is important that we find a structure to let new technology evolve from the laboratory and pilot scale, and reach the commercial level," he said. "We cannot think that, in a short time, forward osmosis could, for instance, compete with traditional SWRO or MED for the next 50 MIGD, but we need to create a set of projects, perhaps initially of small scale, where technologies such as forward osmosis, membrane distillation, etc. can compete for business and find a way to evolve from the R&D level."

The future of desalination

The future for the desalination industry remains bright. While about two-thirds of the world’s desalinated water is produced for domestic/municipal use, desalinated water, including wastewater treated with desalination technologies, can also be used for agricultural or industrial purposes. In fact, industrial users represent 26 percent of the global desalination market and other users are as diverse as power stations, irrigation, tourism and the military.

Major desalination projects have been implemented in such diverse places as the Middle East, Australia, Spain and North Africa, with China and Latin America poised for significant growth. It may be a surprise that the U.S. has the second largest desalination market in the world, after Saudi Arabia, with nearly 80 percent of the U.S. market concentrated in California, Florida and Texas. Most U.S. plants treat brackish groundwater, followed by those making boiler feedwater or process water, though projects like Tampa Bay, which is online, and planned projects such as Carlsbad (California), are aimed at desalinating seawater.

Water scarcity issues will not go away, and experts predict that they will worsen. Desalination is unique in its ability to provide the only new and sustainable source of fresh water on the planet. In that way, it truly is like the well that won’t run dry.

Christopher Gasson, publisher of Global Water Intelligence summed the prospects for desalination this way, "At the moment, around 1 percent of the world’s population is dependent on desalinated water to meet their daily needs, but by 2025, the UN expects 14 percent of the world’s population to be encountering water scarcity. Unless people get radically better at water conservation, the desalination industry has a very strong future indeed."

Patricia A. Burke is the secretary general of the International Desalination Association (www.idadesal.org), the global hub of information for the desalination industry. She can be reached at [email protected].

Data Source: 25th DesalData International Desalination Association Worldwide Desalting Plant Inventory.