Water’s impact on fountain beverages and beverage systems: Part one

Foodservice equipment service dealers often discuss equipment repair and maintenance in terms of “cold side” and “hot side.” For a water treatment company, cold side refers to drinking water, post-mix carb and non-carb fountain beverages, frozen beverages (carbonated and non-carbonated) and ice. Hot side refers to hot beverages such as coffee and tea, steam and warewashing. In this three-part article on water treatment and foodservice, there will be a focus on the cold side, specifically post-mix fountain beverages and ice, and how the condition of the tap water plays a role in both drink quality and equipment function. Ice will be covered in part three, which will be the November issue.

The basics of a fountain beverage system

When I was in high school I worked at a large buffet restaurant in Madison, Wisconsin. One of my responsibilities was replacing the syrup transfer tanks for the beverage system, which was my second least favorite part of the job (my first dislike was busing the tables on all-you-can-eat-crab legs night). The tanks were heavy and sticky and if you didn’t get the valve on correctly, you got sprayed with syrup.

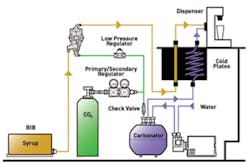

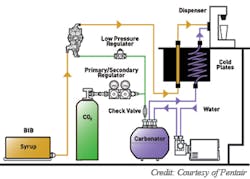

Today, most post-mix fountain beverage systems in the U.S. use BIB (bag-in-box) syrup. In some parts of the world, you will find five gallon syrup tanks called “figals.” The syrup is normally drawn using CO2 powered BIB pumps that propel the syrup to the dispensing valve. At normal operating pressure about 10 percent of the CO2 is used to operate the BIB pumps. Each product has its own dedicated BIB pump.Sometimes a proportioning pump, such as a BRIX pump, is used for non-carbonated drinks. These pumps don’t require CO2 to operate, and instead are powered by the pressure from the incoming water. They are designed to dispense an exact ratio of syrup to water without having to make any adjustments.

The carbonator is a tank with an electric pump. Water is sprayed into the tank where it absorbs the carbon dioxide. Usually, there is one carbonator per dispensing unit.

The syrup and carbonated water often flow through a cold plate, which is placed on the bottom of an ice bin. This serves two purposes: To chill the drinks and to help maintain the ideal carbonation levels. Many times the carbonator itself is integrated into the cold plate system. The water is chilled by the cold plate, then carbonated and then chilled again. This is called “cold carbonation,” as opposed to “ambient carbonation,” where the water at ambient temperature is carbonated and then sent through the chilling system. The advantage of cold carbonation is that less pressure is required (about 70 psi for cold versus 250 psi for ambient).

The syrup and water can also be mechanically cooled by running the lines through a recirculating, or “recirc” is usually the term used, water bath chilled by a compressor and ice bank.

Additional components found on fountain beverage systems include:

- Water boost system raises the water pressure to 90 psi to ensure adequate pressure to all the components of the system and ultimately to the dispenser

- Water pressure reducing valves (WPRV) reduces the pressure to meet the psi requirements of individual components, such as the carbonators and non-carbonated dispense valves

- BIB rack used to hold the BIBs and BIB pumps

- CO2 regulator, which is a high pressure regulator mounted directly to the CO2 cylinder; low pressure secondary regulator is usually mounted to the BIB rack to operate the BIB pumps

- Automatic selector valves (ASV) automatically switch one empty BIB to a second full BIB of the same flavor

- Vacuum regulating valves (VSV) are used on long beverage line runs where multiple BIB pumps are plumbed in series

- Sold out switches (SOS) shut off the dispense valve when a BIB is empty, preventing a customer from filling his cup with only carbonated water

- Back flow preventer prevents the flow of carbonated water or other contaminants into city water supply.

A fountain beverage system is under pressure so when a customer presses the dispense valve, the water flows to the valve in one line and the syrup is pumped through a second line. The water and syrup are mixed at the point of dispense.

In some cases the ice maker is placed directly on top of the fountain beverage dispenser, automatically gravity-feeding to the ice bin. Sometimes the ice maker is in the back of the house and the ice is carried and manually dumped into an ice bin. The ice in a fountain beverage drink not only helps to keep the drink colder longer, but it also helps to keep the carbonation in the drink.

How can water affect fountain drinks, beverage systems and ice machines? A fountain drink is typically five parts water to one part syrup (frozen carbonated beverage ratios vary), so about 85 percent of your soft drink is water. Since ice is 100 percent water, as that melts the ratio increases. Therefore, poor quality water can have a significant effect on the taste and smell of a fountain beverage. What you may not know is that water also affects the performance of the beverage system, the balance of water to syrup and the quality of the carbonation.

Taste, smell and appearance of the drink

The practice of adding a lemon slice to table water was usually to mask a poor taste or smell in the water. With fountain beverage drinks, one method of masking an off taste is to increase the syrup to water ratio. By moving from 5:1 water to syrup to 4:1 water to syrup, for example, the intensity of the syrup can overcome some of the flaws in the water. However, the problem with this is now the syrup costs go up. Also, the flavor profile has changed, which for some consumers may be a problem.

|

SYRUP |

% EXTRA SYRUP |

|

|

Ratio (°Bx)* |

NON-COLA |

COLA |

|

10.5 |

0.0 |

– |

|

11.0 |

4.8 |

0.0 |

|

11.5 |

9.5 |

4.3 |

|

12.0 |

14.3 |

8.3 |

|

12.5 |

19.0 |

12.0 |

|

13.0 |

23.8 |

15.4 |

|

13.5 |

28.6 |

18.5 |

|

14.0 |

33.3 |

21.4 |

|

14.5 |

38.1 |

24.1 |

|

15.0 |

42.9 |

26.1 |

|

15.5 |

47.6 |

29.0 |

|

16.0 |

52.4 |

31.3 |

|

|

EXAMPLE |

OPERATION |

|

1. Syrup to Water Ratio |

12 |

Use refractometer to determine ratio |

|

2. Percentage Additional Syrup |

8.3% |

Record % additional syrup (from % Extra Syrup Chart) |

|

3. BIBs Used Per Month |

36 |

Determine number of boxes used per month |

|

4. Cost Per BIB |

$70 |

Determine the cost per box |

|

5. Cost of Syrup Per Month |

$2,520 |

Multiply #3 by #4 to compute monthly syrup cost |

|

6. Lost Profits Per Month |

$209.16 |

Multiply #2 by #5 to compute lost profits |

|

7. Lost Profits Per Year |

$2,509.92 |

Multiply #6 by 12 months to annualize result |

*Brix = the total sugar solids in a solution, measured in degrees by a refractometer.

An off taste in the drink can be from a number of sources, such as a new flavor being run through a beverage line that previously ran a different flavor. Or, the syrup is expired. Or, the dispensing valves haven’t been sanitized on a regular basis. Or, there is too little syrup in the brix ratio. If you have ever tasted straight carbonated water, it’s sour due to the carbonic acid and low pH. If the restaurant serves unlimited refills, you can bet that the drink will be dumped quickly and refilled with another flavor, costing the restaurant money. Too little CO2 can also cause a flat-tasting beverage.

The most likely reason for an off taste in a fountain drink is the contaminants in the water. Chlorine and chloramines oxidize and break down organic molecules of sugars in water. These reactions will produce many different compounds that can negatively influence the taste of a beverage. These reactions and byproducts can actually amplify the taste of the chlorine. In addition, because free chlorine is a gas, it will gas off along with the carbonation after the drink is poured, creating a “swimming pool” smell.

Due to changes to the Environmental Protection Agency (EPA) Safe Drinking Water Act, limits have been put on the volume of chlorine byproducts allowed in drinking water. As a result, municipalities are moving from chlorine to chloramine disinfection. Chloramine is a small amount of ammonia bonded with chlorine molecules, forming an inorganic compound (NH2CL). Like chlorine, it makes water safe to drink by killing organisms, bacteria and viruses. However, chloramine is more difficult to remove from water and either requires a lot of carbon and long contact time or a special catalytic carbon.

Other taste and odor problems caused by water contaminants include:

- Rotten egg smell, which is caused by hydrogen sulfide in water, produced by bacteria in deep wells and in low-use stagnant water mains

- Earthy and moldy/mildew taste and odors, which are caused by algae, molds and bacteria, such as actinomycetes and cyanobacteria that naturally live in lake and river water sources

- Cloudy – suspended particles can cause light to scatter, giving beverages a milky or cloudy appearance. This suspended matter can be silt, clay, debris from plants, animals, biofilms or particles released during corrosion such as rust; turbidity is a term used to describe water with high suspended solids

- Color – tannins caused by decaying organic matter in surface water will often give beverages a yellowish tint; this is especially noticeable in clear lemon-lime drinks and iced teas.

Also, when you see a lot of bubbles clinging to the side of your beverage glass, that’s usually due to nucleation of the CO2 to the particles on the inside of the glass. This same process can occur if foam cups are used for fountain beverages.

In part two, which will be published in the next issue of Water Technology, the following topics and more will be covered: Carbonation; pH; foaming; sputtering; spraying; flow; and pressure.