It’s recognized that dairies accrue energy-saving benefits by replacing "evaporator need" with reverse osmosis (RO) concentration systems, say engineers and product managers at Dow Water and Process Solutions. Companies even enjoy government rebates when they reduce energy demand by installing RO concentration systems.

More savings are available, continues Dow, when the RO element selected reduces fluid flow requirements while maintaining optimum dewatering efficiency, of which more will follow in a moment.

Because it should probably first be pointed out that the bigger story — behind this particular instance of process and materials innovation — is that technology progress in food & beverage is being driven by developments in water and waste-water technology.

"Food and beverage has the benefit of inheriting technology coming out of water treatment, including reverse osmosis and ion exchange," says Libby Dorundo, a Dow technical expert. "One good example of that is in today’s dairies, where whey is no longer considered a waste product. The processes the dairies are using to produce whey powder come out of the water-treatment world."

Dorundo says when dairy, beer and wine makers have a membrane system they’re in position to make additional use of permeate water. "Start with ultrafiltration and then go to reverse osmosis and you will have the potential to reuse water," she says.

Specifically speaking

Dairy installations may have hundreds of RO elements installed, with each replacement costing roughly $1,000. Dow says its RO membrane element has significant technology advances over others and can reduce operating expenses or relieve capacity constraints in dairy processing.

A modern dairy concentrates whey proteins using ultrafiltration. The permeate stream can then be demineralized using nano-filtration membrane, which concentrates lactose and allows passage of salts into the permeate stream. Finally, the dairy uses RO to concentrate, in other words, dewater, the desired product stream. By using RO for concentration, dairies save on the cost of thermal evaporation and also prevent possible product quality damage during high-temperature evaporation.

As this dairy opportunity is increasingly realized, Dow and other membrane makers have brought to market new solutions appropriate for these uses. One good example, says Dorundo, is RO spiral-wound elements customized for food & beverage, i.e., Dow HYPERSHELL.

At this point, Dorundo says, "continuing use of only evaporation still might work for some small operations, but the numbers strongly suggest that most users making this type of membrane investment enjoy a healthy return."

As a result, many membrane elements are already installed in dairies, but whether a replacement or a greenfield installation is contemplated, fluid dynamics presents users with basic facts. To wit, when an obstruction is introduced into a fluid flow, the flow will seek the path of least resistance. Thus, when you introduce a membrane filter, "flow will try to go around the element scroll and you don’t get needed process separation," Dorundo says.

The obvious solution might seem to be to occupy the entire pipe inner diameter. Yet there is a further complication. These type of dairy operations typically run 20 hours a day, with four hours a day devoted to cleaning.

Solution and example

The claim to fame of the Dow approach, say its developers, is that it is the largest diameter element that still fits in standard, schedule 40 pipe, i.e., a nominal 8-inch tube. The result is maximum flow through the element and thus more separation. The element is actually 7.95 inches in diameter.

The change may seem relatively small, says Dorundo, "but if done in a disciplined manner, it makes a difference."

In addition to better separation, less bypass capacity means the load on the pumps associated with the operation needn’t work so hard. With the Dow solution, it is said, permeate flow will increase for any pump delivering a set flow. For any pump equipped with a variable speed drive, the pumps run slower while delivering the same results.

The Dow solution has additional benefits in installation and maintenance. "The mesh wrapping around other units is rough and can cause cutting. Ours is constructed of polypropylene," Dorundo says.

Also, despite the regulatory intent discussed above, those "other" mesh wrap elements tend to expand over time and do end up inadvertently filling the entire tube. This doesn’t help separation flow, however, because it causes gaps in the mesh that otherwise wouldn’t be there. And it has another inadvertent consequence.

"The elements tend to get stuck in the tubes and prove difficult to remove," Dorundo says. "It’s amazing the creative means crews find to remove them." The Dow solution’s pressure rating doesn’t allow expansion, so the average change-out is reckoned at three times faster.

Documented differences

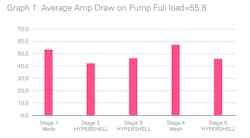

In the case study example provided by Dow, it was invited by a major U.S. dairy producer to measure performance characteristics of competing standard mesh-wrapped elements and its RO elements. The purpose was to compare how the elements impacted fluid-flow requirements and pump energy consumption during whey permeate concentration production.

Dow says its hardshell exterior was shown to reduce flow requirements and pump energy consumption. Cost savings based on a 10-stage, 300-element, 600-gpm, 8-inch whey permeate concentration system were found to be:

- 29 to 45 percent energy cost savings over competitive mesh-wrapped elements

- Up to $438 per element annual cost savings

- Annual projected cost savings of nearly $13,000 per stage

Centrifugal pumps used in the recirculation loops of sanitary RO concentration systems are typically sized to operate at the maximum flow requirement that the system would ever need. However, the maximum flow requirements of a multistage diary concentration system can vary. Bypass area in pressure vessels, fouling and solids levels all can effect flow in the system. The maximum flows will be with high bypass area, lower solids and at low fouling levels.

The energy costs during concentration were caluculated for each stage based on the affinity laws of centrifugal pumps using measured moto frequency output to each of the staged pumps’ frequency drives. As mentioned, the study took place in stages one through five of a 10-stage system. Stages six through 10 contained mixed mesh and Dow elements, and therefore not included in the study. Each stage maintained a constant pressure drop of 50 psi controlled by the VFD of the stage pumps as demonstrated by the stage pressure and baseline pressure.

The study found, in the end, when compared to stages filled with standard mesh-wrapped elements, those equipped with Dow elements drew an average 22 percent amps savings. From this data annual energy cost savings were calculated per element of $438, or an average savings per stage of $12,972.

In summary, Dorundo says, "Mesh-wrapped RO technology will always have its roots in the wastewater industry. Now, a new standard for productivity is offered to the modern dairy plant."