To determine a liquid level using a submersible pressure transducer, take a continuous pressure measurement from the tank bottom or measurement point where the transducer diaphragm is placed. Pressure at a certain depth within a liquid is directly proportional to the column of liquid above it, measured as water column, or WC.

By measuring liquid density, liquid height can be accurately measured. For vented tank applications, the transducer is vented to atmosphere through a tube extending from inside the housing cable end. This allows sensor compensation for barometric-pressure changes outside the tank, more critical in shorter tank installations.

Submersible pressure transducers are cost effective, offer excellent compatibility with liquids, present no issues regarding reflection or foaming, and offer low current consumption for battery-power applications. Fresh water and diesel fuel tanks, as well as chemical totes use submersible pressure transducers for level monitoring.

Note the difference from differential pressure, determined by an up- and down-stream measurement.

An example

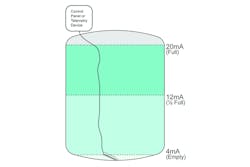

Submersible pressure transducers offer a linear output signal for tank monitoring.

Differential-pressure transmitters are reliable, cost-effective instruments to measure the hydrostatic level of a liquid in a vented or sealed tank.

For a vented tank, the pressure transmitter is mounted to the bottom. Typically, it is threaded into the tank outlet line, side bung, or flange. Since pressure transmitters provide linear output signals, such as a 4 to 20mA signal from zero pressure to the full scale pressure, empty and full respectively, level is monitored based on liquid density and tank height.

For example:

- Density of water at 4°C = 1

- Height of tank = 35 feet = 420 inches

- 27.68 inches of water column = 1 psi

- (420 inches / 27.68 inches of water column) x density of 1 = 15.17 psi

Here, tank height is the basis for defining a measurement range. Since pressure cannot exceed that appropriate to the tank height, based on liquid density, the maximum signal reflects the upper limit of the measurement range.

Output signal selection is always application specific. A 4 to 20 mA output signal is most common in monitoring applications that require long-distance transmissions. Current can be read at the controller as there is no signal loss for hundreds of feet. The downside is that the sensor will require more power, and especially current. For either battery-powered or solar-powered applications, a voltage output signal is ideal. Typically, solar panels are located close to the pressure sensor, so there is no signal loss in the cable.

Application specific

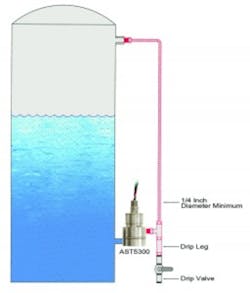

For sealed tanks, differential-pressure transducers are rated for hazardous and non-hazardous application. The high/upstream process connection is installed at the bottom of the tank with the low/downstream side installed with minimum 1/4″ tubing connected to the top of the tank. The larger the pipe diameter is, the less potent for a capillary effect from moisture build-up.

Certain applications use pressure or vacuum pressure above the liquid. In these cases, the pressurized line can be connected directly to the low side of pressure sensor.

In applications where liquid from the tank or condensation might build up in the low line, a drip leg and drain valve maintain accurate level measurement.

By understanding the maximum height of the liquid and its specific gravity, measuring liquid level becomes simple and cost effective.

Overall, differential pressure transducers have the advantage over top-mounted transmitters in sealed tanks in applications where the fluid is reflective, has foam or is clear. Since the measurement is based on the physical force of the liquid on the diaphragm, there is less chance for error.

Karmjit Sidhu is vice president of business development with American Sensor

Technologies.