Next-generation, fouling-resistant RO membranes

Water availability and resources are declining both in volume and quality globally, causing the industrial manufacturers to turn to in-house water treatment systems to purify water sources for use in operations. However, water treatment can be costly if the appropriate technologies and components are not as effective as possible. This is especially true for industrial water users without access to premium quality water sources.

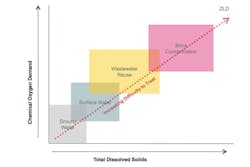

Reverse osmosis (RO) treatment technology has become the gold standard for industrial water users. It provides a low-cost way to produce high-purity water, which is used in boilers, cooling towers and industrial reactions. Years ago, water demand was typically met by treating groundwater or surface waters with low contamination and total dissolved solids (TDS). In light of declining supply, industrial users are increasingly using local wastewater sources and recycling their own process wastewater for operational reuse. These waters contain higher contamination and TDS levels, which can cause sub-optimal RO system operations. RO membranes designed for treating challenging water are necessary for industrial plants to remain efficient and cost-effective.

High contamination levels found in different wastewater sources create fouling challenges including inorganic scaling, colloidal or particulate fouling, organic fouling, and biological fouling1. Inorganic scaling and colloidal or particulate fouling can be addressed with advanced pretreatment technologies to soften (for example, with lime softening or an antiscalant addition) and remove suspended solids (for example through ultrafiltration). Pretreatment technologies to reduce the organic and bioassimilable material in the water – to avoid the latter two types of fouling – are only partially effective2. Consequently, operators rely on advanced RO membranes to treat water with these residual contaminants.

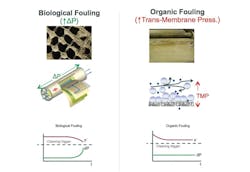

Biological or organic fouling compromises an RO system’s performance and sets off triggers to clean the system and regain performance, both of which cause inefficient productivity. Biological fouling is observed by an increase in the system’s first stage differential pressure (dP). Microbes attach to the feed channel of the RO element and form a biofilm to capture organic nutrients from the water. The biofilm grows and begins to block the feed channel, causing the dP to increase3 4. When system dP becomes higher than 3.5 bar, it can result in irreversible mechanical damage to the RO element and, therefore, must be avoided.

Organic fouling, on the other hand, is observed by the loss of flux of a membrane caused by the accumulation of a contamination layer on the membrane surface that blocks water flow. This results in the need to operate at higher pressures, which consumes more energy5 6. Both biological fouling and organic fouling can be reversed through system cleaning, but this has the negative effects of increasing downtime, increasing costly chemicals and labor, and lowering productivity and membrane life.

The proposal

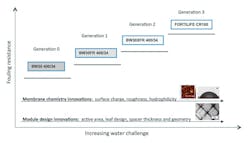

Developing advanced RO membranes that effectively treat challenging waters is essential in the current environment. Next generation RO products, built on legacy performance standards, offer greater fouling-resistance fueled by advances in membrane chemistry and module designs for today’s water types. Fouling-resistant membrane chemistry carefully controls charge, roughness and hydrophilicity. Coupling a membrane with a mechanically engineered module designed to control shear profiles and element efficiency provides a complete package.

Figure 2. System impact of biological and organic fouling

In 2015, a survey of industrial wastewater reuse plant operators revealed that, despite the availability and use of fouling-resistant RO elements, the reliability of their water treatment systems continued to suffer from persistent biological fouling. With this challenge in mind, a latest-generation, fouling-resistant RO membrane was developed to provide relief from biological fouling without compromising the organic fouling resistance advances already made. The features and benefits of the latest, third-generation, fouling-resistant RO membrane are provided in the Table 1.

Table 1. Features and benefits of the latest fouling-resistant RO membrane

A third-generation RO membrane can help provide an exceedingly low pressure drop module design for an 8-inch, 400-square-foot module compared to the previous generation of RO membranes, shown in Figure 4. It is equipped with an organic fouling-resistant membrane chemistry that reduces blocking by organic biofilm attachment and natural organic matter (see Figure 5). Furthermore, after installation, the product reduces cleaning frequency of an RO system, which, in turn, helps improve uptime and reduce maintenance costs.

Figure 3. Generations of fouling-resistant RO technology

The proof

Two biofouling-prone waters were used to compare the new third-generation to the first-generation and the second-generation fouling-resistant membranes. The latest-generation RO membrane offered a demonstrably longer operating time before reaching the highest allowed 3.5 bar dP limit for the system.

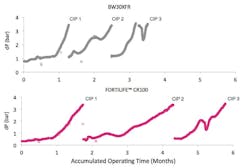

The evaluation of first-generation membranes was conducted in a system with two first-stage pressure vessels. Seven 8-inch-diameter elements each of the first- and third-generation membranes were placed in parallel in an industrial RO skid treating steel and iron wastewater. The two banks of elements were operated at matching flux and recovery. Starting flux was 15 L/m/h, and recovery was 48 percent. The wastewater feed to the RO system had a TDS of 700 to 900 milligrams per liter (mg/L), a chemical oxygen demand of 40 to 60 mg/L, and a history of biological fouling, which caused the industrial skid to experience rapid differential pressure increase after a certain period of operation.

Figure 4. Comparative pressure drop profiles of 8-inch, 400-square-foot RO elements with 34 mil thick brine spacers as a function of feed flow

In comparison to the first-generation RO membrane, the third-generation RO membrane provided, on average, 35 percent longer operating time across six cleaning cycles (see Figure 6). The starting dP of the first-generation membrane was 0.85 bar versus 0.35 bar for the third-generation membrane.

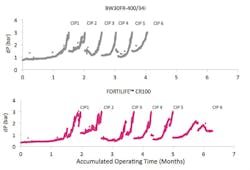

The second-generation technology’s evaluation was conducted in a system with two banks of RO elements (each with eight elements in series, operated in parallel at the same average flux of 22 L/m/h and a recovery of 67 percent). Each bank contained 2.5-inch diameter, scaled-down versions of the third- and second-generation RO membranes. The softened groundwater feed had a TDS of 180 to 200 mg/L and was dosed with bioassimilable nutrients and a total organic carbon range of 2 to 3 mg/L to provide a high-biofouling condition.

When compared to the second-generation RO membrane, the third generation provided, on average, 39 percent longer operating time across three cleaning cycles (see Figure 7). The starting dP of the second-generation membrane was 0.85 bar versus 0.35 bar for the third-generation membrane.

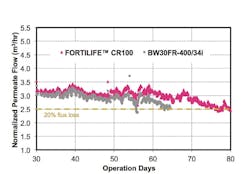

Figure 5. Operating time to reach 20 percent flux loss for latest-generation, fouling-resistant RO membranes

Pushing the boundary with fouling-resistant technology

Developing fouling-resistant technology for high-TDS water sources has, for the first time, been leveraged in membranes to allow industrial water treatment plants to push the boundaries of water reuse and achieve minimal liquid discharge. As described in this article, the new, third-generation allows biofouling-prone treatment plants to experience 30 percent loger operating time between cleanings and benefit from the reduced hassle, chemical cost, labor and system downtime.

Figure 6. Total accumulated operating time across six biofouling periods for the rstgeneration RO membrane (top) and the third-generation RO membrane (bottom)

To treat an entire spectrum of difficult industrial wastewaters, advanced elements to treat high TDS waters with high-productivity and permeate water quality coupled with the latest fouling-resistant technology, have also been developed. The combined use of next-generation, fouling-resistant RO membranes and the advanced, high TDS elements provides industrial operators with the ability to achieve reliable, high-water recovery while operating within standard RO operation pressures.

Figure 7. The second-generation membrane’s (top) and the third generation’s (bottom) total accumulated operating time across three biofouling periods

REFERENCES

- Guo, W., Ngo, H.H., and J. Li. “A mini-review on membrane fouling.” Bioresource Technology. 2012, 122. 27-34.

- Carroll, T., King, S., Gray, S.R., Bolto, B.A., and N.A. Booker. “The fouling of microfiltration membranes by NOM after coagulation treatment.” Water Research. 2000, 34. 2,861-2,868.

- Herzberg, M., Seoktae, K., and M. Elimelech. “Role of extracellular polymeric substances (EPS) in biofouling of reverse osmosis membranes.” Environmental Science & Technology. 2009, 43. 4,393-4,398.

- Matina, A., Khana, Z., Zaidia, S.M.J., and M. C. Boyceb. “Biofouling in reverse osmosis membranes for seawater desalination: Phenomena and prevention.” Desalination. 2011, 281. 1-16.

- Nghiem, L.D., Coleman, P.J., and C. Espendiller. “Mechanisms underlying the effects of membrane fouling on the nanofiltration of trace organic contaminants.” Desalination. 2010, 250. 682-687.

- Agenson, K.O., and T. Urase. “Change in membrane performance due to organic fouling in nanofiltration (NF)/ reverse osmosis (RO) applications.” Separation and Purification Technology. 2007, 55. 147-156.

Tina Arrowood is a research scientist in Dow Water and Process Solution’s RO membrane research and development (R&D) group. She leads a research platform to study the fundamental science of fouling in RO systems to develop fouling-resistant technologies. Arrowood holds a Ph.D. in organic chemistry from the University of Minnesota.

∴

Guillem Gilabert-Oriol joined Dow in 2010 as an R&D engineer. He holds a master’s degree in chemical engineering and processes from the Universitat Rovira i Virgili and a Ph.D. in ultrafiltration. He currently leads the Reverse Osmosis Antifouling team at the Global Water Technology Center in Tarragona, Spain.

∴

Cheng Yang joined Dow in July 2012. He has been involved in multiple R&D projects about fouling-resistant RO, minimal liquid discharge and special separations. Cheng has two world patent submissions, is published in 12 journals and holds a Ph.D. in chemical engineering from Tsinghua University in Beijing.

∴

Jon Johnson’s work relates to spiral-wound modules for RO and includes the development of new spiral-wound element configurations, the design and testing of structural components, and the modeling and optimization of spacer materials. He is a mechanical engineer with degrees from the Colorado School of Mines and the University of Minnesota.

∴

DOW FILMTEC™ FORTILIFE™ RO elements handle challenging waters and applications with performance and support from Dow. DOW FILMTEC FORTILIFE RO elements help reduce water costs, achieve sustainability goals, minimize biofouling problems and move toward minimal liquid discharge. Learn more at http://dowwaterandprocess.com.