Q&A: UV disinfection, an alternative to chemicals and pasteurization

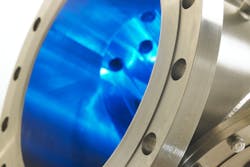

Many microbial pathogens have developed an increased tolerance to chlorine (and other chemical) treatment and pasteurization, and ultraviolet or UV disinfection may be the solution. To protect product and plant quality and brand integrity, validated UV disinfection technology can be used in product liquids, process water or industrial effluent. This technology also reduces energy use and operating costs.

On May 18 (from noon to 1 p.m. CDT), Water Technology will present "Top 5 Trends Driving the Use of UV Disinfection for Microbial Control," a webinar sponsored by Evoqua. Attendees will learn how effective UV treatment can be an alternative to pasteurization, reduce or eliminate the use of chemicals or additives to prevent contamination, achieve water reuse initiatives, and meet industrial effluent requirements.

Some key topics that will be discussed during the webinar are:

- How UV disinfection works

- The top 5 trends driving the need to use UV disinfection

- What to expect in lamp technology, design and performance validation to achieve effective disinfection

The Water Technology team talked with Jon McClean — VP of Research, Development and Engineering, Evoqua and presenter — regarding some of the central information that will be featured during the May 18 webinar.

Why are some pathogens able to withstand chlorine treatment and pasteurization?

When these microbes receive a low dose of chemical for a long time, they develop a tolerance to the chemical. Think about going on vacation and having an immunization shot — it is a similar process. Many species are now chlorine tolerant. These include Giardia, Listeria and Cryptosporidium.

What are a few applications in which UV disinfection can be implemented in the process industries?

Anywhere water is used as a product or as a process. UV is a simple, elegant process that does not affect the flavor, color, chemistry or taste of products as a chemical would. The applications include motive water — using water to move peas or pasta flumes; water for heating, chasing and cooling; and products that are rinsed in water, such as ready to eat products. In addition, chlorine can bleach the product and effect the appearance.

Can you tell us a few benefits that UV disinfection provides when compared to chemicals?

It is simpler with no residual chemicals to remove, no changes in pH, no byproducts formed and no Occupational Safety and Health Administration risks to handle (for example, safety showers are not required).

When compared to pasteurization?

UV disinfection is much quicker. It uses about 1/20 (5 percent) of the energy and is a flow through system, not a batch process. There are now heat tolerant microorganisms, such as Alicyclobacillus, that are triggered to germinate during the heating process.

For more information, watch the video below. To register now, click here.