Breakthrough wastewater treatment for FOG removal

The food and dairy industries face a waste stream of fatty organic materials from animals and vegetables that is not easily disposed of. Collectively called fats, oils and grease (FOG), this effluent is the result of food preparation activities and comes under careful scrutiny from municipalities due to its tendency to cause serious pipe and sewer blockages. Because of the serious cost penalties employed by many local governments and regulatory agencies, professionals in the food and dairy industry are eager for a technological solution that will help them effectively reduce the amount of FOG contamination in their outgoing waste streams.

Why is FOG a problem?

FOG does not mix with water, and when wastes that contain FOG are disposed of in a standard sewer without treatment, the fatty FOG portion of the waste stream can float to the surface and solidify, causing clogging. The improper disposal of FOG waste causes harm to the environment and taxpayers. Pipes that are clogged with FOG can overflow and allow hazardous liquid waste to flow into the environment with no regulation. Then, taxpayer money must be used for repair and replacement of the clogged pipe. A large number of FOG-related pipe repairs in a community can also result in an increase in local monthly water rates.

FOG is a major issue across the U.S. The Environmental Protection Agency (EPA) identifies FOG as the most common source of sewer overflows and estimates that FOG-related issues cause between 5,000 and 17,000 overflows per year. [1] Because the high frequency of clogging, city regulations now set strict FOG discharge levels for municipal sewers and high-cost penalties for those unable to meet discharge requirements. These penalties can add up quickly for food and dairy operations and bleed millions of dollars from company revenue each year, causing many in the food industry to implement waste treatment technologies.

Methods of managing FOG

The most popular methods of managing FOG contamination are not economically optimized and leave much to be desired in the way of on-site waste treatment. Traditional grease interceptors effectively trap FOG for manual removal, but they are high-maintenance and require operators to schedule frequent grease trap cleanings. Other frequently used FOG removal processes rely on filters or membranes. While these systems also effectively remove fatty contaminants from wastewater streams, they are easily clogged if fed high concentrations of FOG and are unsuitable for large food and dairy operations. Because technologies like grease interceptors, filters and membranes require frequent maintenance, they are associated with high on-site operational costs and are not a viable solution for today’s expansive food and dairy industry. With reliability and efficiency assurance posing key pain points, many companies are motivated to pursue new, more efficient wastewater technologies that offer promise for effective FOG removal.

A new treatment introduced for FOG removal

Advanced water treatment processes are proving to be vital to the food and dairy industry’s FOG management efforts. A next-generation wastewater treatment process is designed to efficiently remove FOG contaminants on-site. The process combines electrically induced gas flotation and advanced oxidation to quickly remove fats, oils and greases from food and dairy waste without heavy reliance on filters or other membrane-based removal technologies.

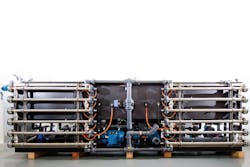

Electro Water Separation (EWS) is a highly scalable and continuous process that uses small doses of electricity to gather FOG and other suspended solids for easy removal. Advanced oxidation (AOx) relies on powerful oxidants generated when the wastewater stream contacts a series of proprietary electrodes. OriginClear’s combined process, EWS:AOx, is fast, versatile and low maintenance. It has a small on-site footprint, uses a low amount of consumables and cost-efficiently treats food and dairy wastewater.

Putting the solution to the test

In September 2017, OriginClear completed a demonstration with a Texas-based dairy farm that was facing seven-digit annual state fines because its wastewater did not meet local FOG requirements. In under one hour of operation, the process removed 96.6 percent of the FOG contamination in the farm’s wastewater stream.

Testing began with a 1-liter sample of the dairy farm’s effluent. To optimize the wastewater for efficient FOG removal, the total dissolved solids of the solution was increased using common salt. Once the wastewater sample was prepped, three tests were conducted using OriginClear’s EWS flotation module – one 3-liter 30-minute treatment (measured at 15-minute intervals) under a 15.5-volt (V) voltage and one 3-liter 45-minute treatment under 10V (measured at the 45-minute mark). The results from these tests are shown in Table 1.

After the 3-liter effluent sample was treated for 15 minutes at 15.5V, the dairy farm’s wastewater saw an 85-percent reduction in turbidity, or the concentration of suspended particles, a 53-percent reduction in FOG contamination and a 64-percent reduction in biological oxygen demand (BOD). The 30-minute treatment was even more effective: Turbidity was reduced by 91 percent, FOG contamination was reduced by 76 percent, and BOD was reduced by 63 percent.

When the 3-liter sample underwent a longer 45-minute EWS treatment with a lower 10V electrode, FOG contamination was reduced by 96.6 percent. The 45-minute residence time also reduced turbidity by 89 percent and BOD by 60 percent.

Results

The results from this demonstration test show how advanced water treatment technologies can provide an energy- and cost-efficient solution for reliably managing FOG contamination. A pilot system with an approximately 125-gallon-per-hour treatment capacity has been built and is under implementation. With further testing and commercial adoption of EWS and similar technologies, the food and dairy industry can affordably remove FOG from wastewater streams to protect the environment and the local community.

RESOURCES

- Oil and Grease Removal, EPA Region 8 Conference, May 12th -14th, 2009, Kyle Sorenson. https://www.epa.gov/sites/production/files/documents/W6_KyleSorenson_OilAndGreaseTechnology.pdf.

Jean-Louis “JL” Kindler is president of OriginClear Technologies and leads the commercialization of OriginClear’s water treatment technology. He has been an executive and engineer in environmental technologies for 25 years. Before OriginClear, Kindler was co-founder and chief technology officer of Ennesys, the company’s French joint venture, where he designed its patent-pending waste-to-energy system.