Nanotechnology in the water treatment market sees growth potential

A high demand for treated water produced through nanotechnology exists in the pharmaceutical, food and beverage, chemical and oil and gas industries. This has given rise to a well-defined nanotechnology in water treatment market to exist in a global perspective. With it used in water treatment and purification processes, the associated market is expected to grow in the future.

Apart from the membranes, nanoparticles also are highly effective in facilitating water treatment processes in the water treatment market. Nanomaterials in the particulate form consist of various features. These features make them an effective medium for carrying out treatment processes. Features include:

• Ability to facilitate fast chemical reactions

• High durability, stability and strength values

• Ability to change physical, biological and chemical properties

• A high surface area with less volume

Membranes, nanowires, magnetic nanoparticles and other catalyst agents find use in expediting water purification in the nanotechnology in water treatment market.

Pharmaceutical

Nanomembranes play a vital role in water treatment processes that involve the removal of contaminants and softening actions. This is crucial in pharmaceutical product manufacturing. The demand for quality pharmaceutical products increases with improving healthcare.

Oil and gas

In oil and natural gas extraction, water treated with new techniques like nanotechnology is required in massive quantities. Purposes such as lubrication, cooling, drilling and cleaning — among several others — mainly involve implementing treated water.

Power generation

Treated water is used with an intention to fulfill the purposes listed above in power generation processes. With industrialization and urbanization pushing ahead, the demand for power mainly in the form of electricity also is experiencing a surge. Thus, with more power generated than before, companies require large volumes of purified water.

Conclusion

Setting up nanotechnology in water treatment for industrial purposes can be expensive. This exists as a key factor restraining nanotechnology in water treatment. Although, companies are looking forward to change this by pouring investments and reducing installation costs. This could help the technology overcome its challenges.

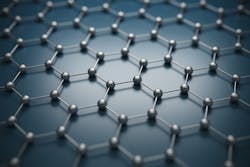

Like any other scientific field, nanotechnology is changing every day as new inventions and innovations grace its functioning module. Now, scientists are focusing on using graphene technology to give rise to a never-before-achieved quality of nanotechnological filtration. Few researchers have also made molybdenum disulfide (MoS2) into thin membranes for use in the global nanotechnology in water treatment market. As progress in research and development (R&D) offers a widespread scope for the market to develop, most companies are focusing on the same in the global nanotechnology in water treatment. ItN Nanovation AG, Lanxess Aktiengesellschaft, and Enel Spa, are some of the major companies existing in the global nanotechnology in water treatment market.

Moiz Adenwala is the assistant manager at Transparency Market Research. He has written about science and technology for eight years. Adenwala’s experience focuses on Internet of Things (IoT), nanotechnology and viritual reality.