Portable Analyzer Offers Simplified On–Site FOG Analysis

By Sandy Rintoul

Monitoring the amount of fat, oil and grease in wastewater discharges is becoming increasingly important. A simplified FOG analysis procedure using a portable infrared analyzer can now provide regulators and plant operators with on–site results in less than 10 minutes.

Infrared analysis of oil and grease has been used in the petroleum industry on highly regulated off–shore oil platforms for over 30 years. EPA Methods 413.2 and 418.1 are infrared methods for oil and grease measurement using the now banned Freon to extract hydrocarbons from effluent. EPA Method 1664 using hexane as the extraction solvent and gravimetric analysis is now the standard method replacing Freon methods. However, the gravimetric procedure requires a skilled laboratory technician and is a time and equipment intensive process.

The ASTM has passed an alternate method, D 7066–04, using a Freon replacement solvent, S–316, and simplified infrared analysis. An alternate infrared method uses hexane extraction and evaporation.

The measurement by infrared absorption makes use of the fact that hydrocarbons such as fats, oil and grease can be extracted from water or soil through the use of an appropriate solvent. The extracted hydrocarbons absorb infrared energy at a common infrared wavelength and the amount of energy absorbed is proportional to the concentration of the oil/grease in the solvent. This can be directly calibrated or converted to the ppm amount of oil in the original sample.

Measurement Procedure

An advantage of infrared analysis is the ease of use and the quick analysis time. Portable, relatively inexpensive fixed filter infrared analyzers such as the Wilks InfraCal TOG/TPH Analyzer allow for on–site analysis by regulators or industrial pretreatment personnel. The extraction and measurement procedure is simple enough for an operator with minimal training to do the analysis.

A measured amount of sample (typically 100 ml) is collected in a container. Solvent (either hexane, perchloroethylene or S–316) is added at a ratio of one part solvent (10 ml) to 10 parts sample. After shaking for two minutes a portion of the solvent extract is put into the sampling device and in 30 seconds the result is displayed. The analysis from sample collection and extraction to final result is complete in less than 10 minutes.

Solvents Choices

With the ban of Freon, several replacement solvents are now used for extracting the FOG from the water sample. S–316 solvent as called for in the ASTM method D 7066–04 or spectroscopic, hydrocarbon–free grade of perchloroethylene are good infrared solvents as they totally lack a C–H absorption band. The solvent extract is placed directly in a quartz cuvette, a beam of infrared light goes through the extract for an infrared transmission measurement and the filter/detector set for C–H absorbance measures the hydrocarbon content in the extract. Because there is no evaporation step, the volatile hydrocarbons remain in the sample and are included in the measurement. Either solvent can be reclaimed for reuse.

The minimum detection for this method using a portable fixed filter infrared analyzer is 2 ppm.

Since EPA Method 1664 defines oil and grease as “hexane extractable material”, it makes sense to use hexane for extraction. Because hexane contains hydrocarbons, it must be evaporated off in order not to interfere with the infrared hydrocarbon measurement of oil and grease. Using an exposed sample plate with an ATR (attenuated total reflection) crystal, a measured amount of the hexane extract is deposited on the sample plate, the hexane evaporates and leaves a film of oil and grease on the crystal for an infrared measurement. The ATR crystal material is cubic zirconia which is scratch resistant and the exposed sample plate makes for easy cleaning and sample presentation.

The minimum detection for the ATR sample plate with a fixed filter analyzer is 8 ppm.

Analysis Methods

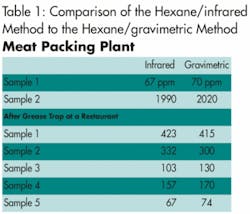

FOG is a difficult analysis because it is not a unique chemical entity. The definition of FOG is dependent on the procedure and solvent used. Because different testing methods are looking at different physical properties of FOG, there can be differences in the analysis. Table 1 shows a comparison of the hexane extraction and infrared measurement method to the hexane/gravimetric method (EPA 1664). One data set is from a meat packing plant and the other from samples taken after a grease trap at a restaurant. As it is difficult to get two identical grab samples from a waste stream, the two methods correlate very closely.

Conclusion

Using portable infrared analyzers with an infrared procedure enables operators of a pretreatment system to easily assess their system’s efficiency. Plant operators can take samples before and after treatment to see how their system functions under heavy loads. System parameters can be changed and the results of the changes can be determined on–site without waiting for laboratory results. Regulators from a POTW can take samples from the source and immediately determine who their FOG offenders are. Most importantly, effluent with high levels of FOG can be stopped before it stops the flow of the sewer line.

About the Author:

Sandy Rintoul is product manager and technical support for the InfraCal TOG/TPH Analyzers at Wilks Enterprise Inc. (www.wilkir.com). She chaired the ASTM committee for Method D 7066–04 for oil and grease analysis by infrared determination. She may be contacted via e–mail at [email protected].