Dosing Program Helps Clear up Odor, Corrosion Problems

Pinellas County, FL, has a rich history and culture, from early Native American settlements to the arrival of Spanish conquistadors in the 1500s, to pioneering citrus farmers, railroad barons and entrepreneurial land developers. Present day visitors find a prosperous and enjoyable place to live, work and play.

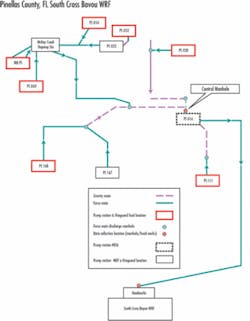

Pinellas County has two wastewater treatment facilities, the W.E. Dunn WRF to the north and the South Cross Bayou WRF serving the southern part of the county. For the better part of the past decade iron salt has been used as a means of controlling H2S gas within the South Cross Bayou collection system. Those lines primarily feed into Master Pump Station #016.

The PS #016 collection system covers a large geographic area with retention times reaching greater than 18 hours. This slow-moving flow has produced low surface pH (corrosion) and high H2S gas levels (odor complaints). This segment of the collection system makes up ~35% of the flow received at the South Cross Bayou WRF.

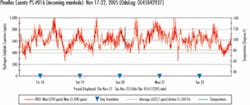

Pinellas County has fought with H2S-related odor complaints at PS #016 for years. Even with iron salts dosing, gas levels typically averaged 623 ppm inside the incoming manhole serving PS #016.

WW Utilities Director James Rolston and his staff were looking for an alternative. In 2005, they were introduced to Premier Chemicals and its product line known as Thioguard TST.

Thioguard® is an alkaline magnesium hydroxide slurry, Mg(OH)2. Considered a “technical grade” magnesium hydroxide suspension, it is similar to the more familiar pharmaceutical grade “milk of magnesia” used to alleviate acid indigestion. It is a non-hazardous product that is not harmful to humans or the environment.

Odor and corrosion problems in sanitary sewer systems is the result of a two step biological process. Sulfate reducing bacteria present in the collection system convert sulfates into hydrogen sulfide gas. A series of oxidizing bacteria that reside on the sewer crown convert hydrogen sulfide gas into sulfuric acid which will eventually result in a substantial lowering of surface pH, frequently to values below 2.0.

Adding magnesium hydroxide to municipal wastewater suppresses hydrogen sulfide gas formation by increasing and stabilizing pH. At near neutral pH, relatively small adjustments in pH results in large changes in hydrogen sulfide production. At pH 7.0 approximately 50% of the hydrogen sulfide remains dissociated in solution. Nearing pH 9.0, hydrogen sulfide levels drop to less than 1.0%. Small additions of magnesium hydroxide sufficient to raise wastewater pH in this range can significantly reduce hydrogen sulfide gas emissions, and thus help control odor/corrosion problems.

Thioguard is typically supplied as a pumpable “latex paint like” aqueous suspension, ranging from 53 to 65% solids. To control H2S buildup, the product is proportionally added to the collection system at pump stations at a rate varying from 25 - 100 gallons of product per million gallons of wastewater.

When Thioguard was added to the Pinellas County system, the H2S gas levels dropped to an average of 48 ppm. This >91% reduction of H2S gas coming into PS #016 has resulted in the reduction of scrubber operation and subsequent cost at this pump station. Also, the surface pH inside the incoming manhole to PS #016 increased from a pH of 2 to a near neutral pH of 7 within four months.

Jim Dulaney, Wastewater Treatment Manager at the South Cross Bayou WRF, said the stabilized pH and added alkalinity coming into the plant has helped reduce chemical consumption and costs of the two-stage influent scrubber at the plant headwork’s by >25%.

The increase in surface pH prompted Doug Decker, Operations Department Project Coordinator for PS Rehabilitation, to model the surface pH of the entire W.E. Dunn WRF collection system. The model was an eye opener insofar as the severity of corrosion rate within the system. It demonstrated that 39% of the pumping stations in the North Pinellas County Collection System has a surface pH below 4.

James Fletcher, WW Treatment Manager at the W.E. Dunn WRF, has identified a line segment within the north system to treat with Thioguard to curb H2S gas and reduce the corrosion by raising surface pH levels. This evaluation will take place during the summer of 2006. Gas levels and surface pH readings will be monitored and reported.

Thioguard is a patented process of Premier Chemicals, LLC, and is produced in two U.S. locations; Gabbs, NV (mined grade), and Port St Joe, FL (sea grade), with several tolling locations nationwide.

About the Author:

Ronn Chase, Senior Project Manager, has been with Premier Chemicals since the inception of the Thioguard Product line. He has worked extensively for two decades in the wastewater transmission line industry and can be contacted at 623-972-7673. For more information, visit the company’s website at www.premierchemicals.com.