Bearing, Lubrication Issues that can Reduce Pump Life Cycle Costs

By Allan R. Budris

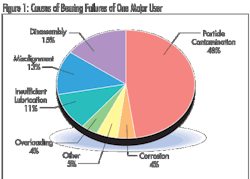

In my February 2008 column, I stated that pump bearing failures are the second leading cause of pump repairs, after mechanical seals. Further, I pointed out that most pump bearings do not reach their theoretical (L10) fatigue life. Two-thirds of all rolling element bearings in service, which had to be replaced, failed prematurely. By comparison, only one-third of bearings fail due to fatigue spalling (L10 Life), see figure 1.

In this column I would like to expand on the February 2008 column which mainly focused on "Oil Mist" and "Synthetic" lubrication to improve bearing life. This month I would like to cover such additional important bearing/lubrication life issues as pump flow rate, oil viscosity, lubricant temperature, oil oxidation, oil contamination, and oil life.

Bearing Load Life Basics

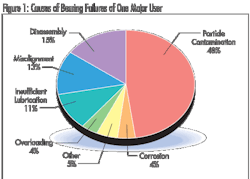

First a few basic facts about rolling element bearings: Most antifriction bearings are precision made from hardened carbon steel, which means that they can tolerate very little surface degradation. The statistical life ratings (L10) are based on metal fatigue failure, with 90% of the bearings surviving for the rated time period. Further, the fatigue life varies with the cube of the bearing load, and is inversely proportional to speed. The primary load on the pump bearings comes from the pressure unbalance around the impeller (in a volute), especially at off-design flow conditions, as shown in figure 2. It should be noted that most pumps have single volute casings. Therefore, based on the fact that radial load forces rise sharply at very low and very high flow rates, one way to improve bearing life is to operate the pumps as close to the pump best efficiency point as practical for the application.

Bearing Lubrication Life Basics

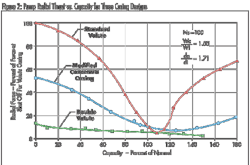

For proper lubrication of a rolling element bearing, the lubricant must poses the minimum viscosity value required to establish an elastohydrodynamic oil film between the balls (or rollers) and the inner and outer races. This is the single most important oil property. Ball and cylindrical roller bearings need a minimum oil viscosity of 70 SSU at the maximum operating temperature to obtain this oil film. A viscosity of 100 SSU is required for spherical roller bearings, with 150 SSU needed for spherical roller thrust bearings.

Therefore, since oil viscosity decreases with temperature (see figure 3), higher temperatures require higher viscosity grades of oil. Centrifugal pumps are typically lubricated with ISO Grades of 32 through 100.

Temperature

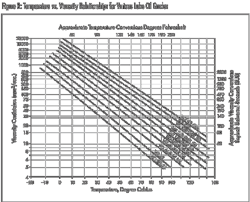

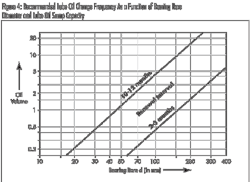

Since ball and roller bearings can tolerate up to about 250o F before the surface hardness is compromised, the lubricant normally becomes the limiting factor for high temperature operation. As noted above, higher temperatures reduce oil viscosity, which must normally stay above 70 SSU. Using higher viscosity oils does not, however, address oil life, since oil life is dependent on the oxidation of the oil which increases with increasing temperature. Oxidation causes the formation of acids, gum, sludge and varnish. The oxidation rate of the oil depends on the fluid type, methods of refining and oxidation inhibitors. Below a temperature of 140oF, the oxidation rate remains slow, but it doubles with every 18o F increase in oil temperature. Figure 4 shows typical oil change interval recommendations for petroleum base oils. Oil change intervals should be more frequent for higher temperatures.

Normal operating conditions should be in the 125 – 140oF range for optimum oil life. Over 180o F, the use of synthetic oil should be considered, and above 200oF, the use of synthetics should be mandatory.

Factors Causing High Bearing /Lubricant Temperatures:

The following factors will increase oil and bearing temperatures:

- The load on the bearing: High relative bearing loads will increase bearing temperature. Factors that can increase the bearing load include:

- a. The pump flow rate.

b. Misalignment of the bearings.

c. Heat from the pumped fluid expanding the shaft into the bearing inner race.

d. Cooling of the housing (not the oil) will restrict the expansion of the bearing outer race, increasing the internal bearing load. Do not jacket-cool bearing housings. Stuffing box cooling is generally more effective and preferred when handling hot liquids. - Higher oil viscosity increases oil and bearing temperatures, so the oil grade should not be higher than necessary. Synthetic oils will often allow lower oil grades. Higher oil viscosity also increases the power loss from the bearings, which slightly increases life cycle costs.

- Oil level too high: The oil level should not be above the center line of the lowest ball / roller, to prevent overheating of the oil.

- Too much grease: Greased bearings will generally run hotter than oil lubricated bearings, and over-greasing will increase the bearing temperature even further.

- Higher speed pump operation increases the bearing temperature and, when the bearing diameter in mm times the shaft speed in rpm (Dn-values) is near or above 160,000, excessive heat generation can be expected.

- Lifetime (grease) lubricated bearings should not be used in continuous use when the Dn value exceeds 80,000, to avoid excessive heat.

Other Lubrication Factors Impacting Bearing Life

The following additional factors can further increase bearing life:

- Consider hermetically sealing the bearing housings with magnetic shaft seals and closed system (balanced) oilers, with no vent plugs. This will keep out moisture and dirt, which can greatly extend bearing life.

- Prevent abrasive dirt from entering the lubricant before it reaches the pump, with proper storage and handling. Keep reservoir hatches closed, use air filter-breathers on all reservoirs, and clean reservoirs before installing new oil. Further, filter all oil introduced into the reservoirs/sumps with the use of a filter cart or off-line filtration.

- Ascertain that bearing fits comply with specifications.

- Ensure that the approved grades of oil or grease are used.

- Do not permit oil levels to go higher than the center of the lower ball.

- Do not mix incompatible greases.

- Use synthetic lubricants.

- Consider dry sump oil mist lubrication for maximum life.

Reference: "Pump User's Handbook, Life Extension" by Heinz P. Bloch & Allan R. Budris, Third edition, 2010, by Fairmont Press, Inc. WW

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles