System to treat frack water at Eagle Ford Shale site

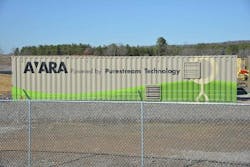

SALT LAKE CITY, UTAH, Aug. 27, 2013 -- Purestream Services will deploy its AVARA brand vapor recompression commercial water treatment system for a Texas Eagle Ford Shale gas producer in Gonzalez County, Texas. Purestream Services has been contracted to treat the wastewater at a centralized water treatment facility near Gonzalez, Texas. The facility was built to accommodate produced water from shale wells operating in the vicinity. Treating wastewater nearer to the source of the production reduces the costs of processing the produced and frac flow-back water and minimizes the environmental impacts of hauling the wastewater long distances. "Oil and gas producers are looking for cost-effective water treatment processes that reduce the long distances required to haul water for disposal," stated Purestream CEO Neil Richardson.

###