Desert Power Plant Operators High on Capillary UF Membranes

Effective wastewater treatment is vital to maintaining power production and, to that end, new membranes used at the High Desert Power Project in Victorville, Calif., have earned high marks from plant operators.

This power plant lies northeast of Los Angeles off of Interstate 15 in the Mojave Desert, using combined-cycle technology that implements three gas turbines and one steam turbine. Currently, this combined-cycle technology is one of the most environmentally friendly and energy efficient models available for fossil-fuel plants of this size and scope. The High Desert Power Plant uses a third less fuel than comparable plants, with significantly reduced air emissions.

Recently, the operators at the High Desert Power Project praised Hydranautics' capillary ultrafiltration (UF) HYDRAcap® membranes for their reliability and excellent performance. The California Aqueduct, the plant's feed water source, offers specific challenges due to high salinity combined with some microbiological organic and inorganic contaminants.

Tony Penna, the Plant Engineer at the Victorville facility, said the six-rack, 114-module 60" system is working very well and with minimal attention after installation was completed in early 2003. On average, each of the six racks produces approximately 400 gallons per minute (gpm) and averages 95% recovery. This is a zero liquid discharge plant with final solids loading being reduced by a crystallizer. The crystallizer converts dissolved ions to crystals which can then be disposed of as solids.

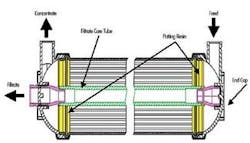

The total HYDRAcap UF system treats over 2 million gallons per day (mgd). The 0.8-mm capillary membrane modules are being used to pre-treat surface water from the California State Water Project's California Aqueduct inflow. It and the 1.2 mm HYDRAcap-LD (large diameter), offered in 40''and 60'', are UF treatment technologies that provide single-step treatment, fouling resistance and chemical-free operation at high recovery rates.

About 60% of the feed water received at the plant is used in the actual power processes. The remaining 40% is treated with the capillary UF system to meet state potable water standards and is dedicated to the local aquifer replenishment. There are four injection/ extraction wells located to the south, all within seven miles of the plant. The wells are transfer systems that are operated by the local Victor Valley Water District.

The year the plant went on-line it won the 2003 Power Plant of the Year by Power Magazine. In addition, this year it won the Mojave Desert Air Quality Management District's Exemplar Award which is given to companies that make significant efforts to reduce air pollution.

The capillary UF membranes provide superior pretreatment when compared to conventional methods such as clarification or multi-media filtration. At the High Desert Power Plant system, the UF is the final step before transition to the water district's system. They follow a high flow contact clarifier and a multi-media gravity filter. The membranes use a hydrophilic, polyethersulfone fiber. The modules also provide at least 4-log removal of pathogens, including Giardia, Cryptosporidium and viruses, both meeting the requirements of the California Department of Health Services and the Environmental Protection Agency's proposed Long Term Enhanced Surface Water Treatment Rule.

Since start-up in February 2003, the system has been running virtually non-stop at the Victorville facility for well over a year – ample time for broad spectrum evaluation. At the High Desert Power Plant, Penna has made it clear that the UF capillary membrane modules have offered "excellent performance and reliability."

For more information, contact Hydranautics at 800-272-7873 or www.membranes.com.