Cutter Pump for Clog-Free Pumping

The Tsurumi Cutter Pump was designed to resolve common clogging issues due to inorganic materials such as cleaning and hygiene products flushed into municipal wastewater systems. However, the Cutter Pump has proven to be very effective in a multitude of different applications including retail stores; restaurants; sewer bypass; nursing homes and housing developments; prisons; hospitals; pulp and paper mills; industrial processing; oil refining; food processing; farming; campgrounds; and hotels, to name a few.

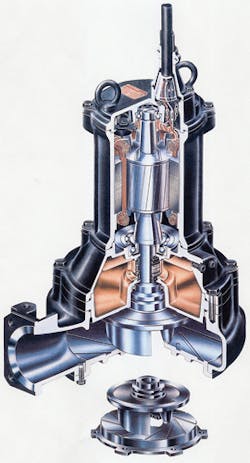

The Cutter Pump functions by handling solids with a unique tungsten carbide cutter which is brazed onto the impeller vane and rotates along the serrated entry of the cutter plate. Incoming fibrous matters are then cut up and, once shredded, are easy to pass through pipes without causing any clogging, particularly in difficult-to-pass spaces like valves and elbows.

Tsurumi Pump’s Cutter Pump cuts materials to provide clog-free pumping.

The carbide blade and the saw-shaped edge of the suction plate work together to form the cutting mechanism. The particles are shredded and pumped together with the wastewater by the non-clog impeller. The entire process is kept running with the help of the oil lifter, an exclusively patented component of the Tsurumi Cutter Pump. The oil lifter utilizes centrifugal force, supplying lubricating oil to the upper seal faces even if lubricant falls below the rated volume or if the pump is oriented horizontally.

Inside view of Tsurumi Pump’s Cutter Pump plus impeller.

The Cutter Pump is available in two versions, free standing and guide rail, and comes with either vertical or horizontal flange connections. The optional discharge size is 3” and 4” with an overall reduced width, which allows the pump to be used in confined areas. The Cutter Pump has proven to be extremely reliable and is an ideal pump for a notable range of applications. IWW

Tsurumi (America) Inc., a division of Tsurumi Manufacturing, has been an innovator in the pump industry since 1924. For additional information, visit www.tsurumipump.com.

Circle No. 154 on Reader Service Card