Product Showcase

Wastewater pond aeration

Aeration Industries won an Environmental Business Journal (EBJ) Business Achievement Award for its successful deployment of the Tri-Oval® Oxidation Ditch wastewater treatment system. It integrates its Aire-O2 Triton process aerator/mixer into the Oxidation Oval format, providing subsurface horizontal mixing at sufficient velocities to prevent solids from settling without need for covers. This permits longer entrainment of the unit’s fine bubble diffused air and allows for deeper ditch designs with smaller footprints. Aeration Industries International Inc., Chaska, MN, 952-448-6789, www.aireo2.com

Valve status monitors

Bray Controls expanded and improved its Series 52 2N1 ProxSensor line of valve status monitors to include AS-i, DeviceNet™ and PROFIBUS® DP BUS network units with a solenoid drive, plus new features across the entire line. The unit combines two proximity sensors in one compact, self-contained and fully sealed enclosure. These monitors deliver the rapid, bounce-free electronic valve signaling required for PLC, computer and solid-state circuitry used in process control and information networks. Bray International Inc., Houston, TX, 281-894-5454, www.bray.com

Turbidity analyzer

With its a multi-beam optical sensor, intelligent microprocessor-based design and self-cleaning technology, the new Triton TR8 Turbidity Analyzer’s sensor electronics constantly adjusts turbidity signal readings versus the reference detector for superior measurement accuracy. A built-in digital filter helps suppress potentially interfering signals while self-monitoring diagnostics assure high reliability. The sensor assembly relies on a long-life near infrared LED light source (880 nm), and the 90° scattered light method in accordance with ISO 7027/EN 27027. Electro-Chemical Devices Inc., Yorba Linda, CA, 800-729-1333, www.ecdi.com

Nuke water cleanup

Graver has a new line of advanced stainless steel backwashable precoat septa for reactor water cleanup (RWCU), fuel pool and other specialty applications in nuclear power generation. Aegis PowerGuard® all metal septa are designed to fit original Graver bottom tube sheet installations with OEM supplied nuclear adapter end fittings. This avoids removal of original hardware to minimize internal damage and personnel exposure during replacement. Elements incorporate Poroplate®, an advanced sintered metal design that allows for precise control of porosity (2-200 µm). Graver Technologies LLC, Glasgow, DE, 800-249-1990, www.gravertech.com

Water level monitoring

From advanced aquifer characterization to long-term monitoring to economical data collection, In-Situ Level TROLL® instruments provide accurate results and reliable operation – even in harsh conditions. They measure and log water level, temperature, and pressure. With five instruments to choose from, you can select the right equipment for your monitoring needs. Depending on the project, the instruments meet application requirements with true logarithmic, step linear, linear average, event, and linear logging modes. In-Situ Inc., Fort Collins, CO, 970-498-1638, www.in-situ.com

H2S toxic gas sensor

Sierra Monitor’s hydrogen sulfide (H2S) gas sensor module, Model 5100-05-IT, received FM Performance approval for both hazardous location operation and performance. This gives it the first approval for a six-month calibration interval, the longest calibration interval in the industry. Thus, maintenance costs for this unit are half that of other area safety toxic gas sensors. IT Series hazardous gas detectors allow system integrators and instrumentation engineers to interface these sensors into their plant-wide safety and monitoring systems. Sierra Monitor Corp., Milpitas, CA, 408-262-6611, www.sierramonitor.com

Water analysis

Krohne will showcase several of its newest instrumentation offerings for the process industries at the American Water Works Association ACE ’09 trade show (Booth 339) in San Diego in June 2009. Among these, the WATERFLUX 3070 – ideal for use at remote water sources or wells or for network data transfer – is an electromagnetic water meter, the OPTISOUND VU30/31 – capable of liquid level measurement to ranges up to 30 ft. – is part of the ultrasonic transmitter family; and the OPTISENS AAM1050 is a ready-to-connect measurement system for measuring free chlorine. Krohne Inc., Peabody, MA, 800-356-9474, www.krohne.com/northamerica

Lab sequencers

Protein sequencing by automated Edman degradation chemistry is a simple, robust solution for many laboratories. Shimadzu now offers its automated PPSQ protein sequencer, an N-terminal protein sequencing solution, to U.S. researchers. First launched in Japan, it’s provided international life sciences researchers with enhanced methods for determining amino acid sequences for nearly 20 years. Specialized software incorporates control functions for the reaction unit and high-performance liquid chromatography analysis, enabling easier sequence analysis of proteins and peptides. Shimadzu Scientific Instruments Inc., Columbia, MD, www.ssi.shimadzu.com

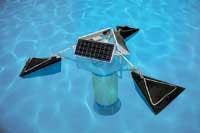

Solar-powered circulators

Creating a gentle, near-laminar flow that helps improve water quality and biodiversity, the SolarBee® v18 solar-powered, long-distance water circulators are ideal for lakes, potable tanks and wastewater storage basins. The new units represent a milestone in the company’s Long Distance Circulation™ technology, including electronic improvements, optional SCADA outputs and higher efficiency. Together with its solar-powered operation, these improvements make the floating circulators an economical, efficient solution to water quality management. SolarBee Inc., Dickinson, ND, www.solarbee.com