Minimizing Water Pollution Through Nutrient Recycling

By Jeff Gunderson

Pork and dairy operations are responsible for managing substantial volumes of high-strength organic wastewater every year, but they also must contend with large amounts of animal manure. According to the U.S. Environmental Protection Agency (EPA), livestock producers manage more than a billion tons of animal manure on an annual basis. These nutrient-laden wastes can be a major contributor to nutrient pollution in many U.S. waterways and lakes, causing algae growth and leading to severe water quality impacts.

As an example, data from the Chesapeake Bay Program (CBP) revealed that of the nitrogen and phosphorus placed on lands that drain into the Bay, animal manure is the largest source, accounting for 40 percent of the total nitrogen and 54 percent of the total phosphorus that enters the Bay. Nutrients washing out from soils that contain livestock manure have seriously damaged the health of local rivers, streams, and the Bay, according to the CBP.

However, nitrogen and phosphorus are also valuable fertilizers, and if these nutrients can be feasibly extracted from manure, then the dual benefit of creating a resource from a waste and preventing nutrient pollution in water resources could be realized.

With these factors in mind, the EPA, in partnership with pork and dairy producers, the U.S. Department of Agriculture, and environmental and scientific experts, has introduced the Nutrient Recycling Challenge (Challenge), a global competition to develop cost-effective technologies that are capable of recycling nitrogen and phosphorus from manure supplies.

According to the EPA, wet manure can be difficult and costly to manage and transport due to its weight, but nutrient recovery technologies could offset these costs by extracting and/or transforming the nutrients in manure into products that could be used onsite, transferred, or sold. Scientists and engineers are already developing technologies that can recover significant percentages of nitrogen and phosphorus from manure for beneficial uses, but these technologies are not yet economically viable and the markets for the products they yield are immature or non-existent.

However, realizing the tremendous opportunity to generate environmental and economic benefits from manure but also recognizing that further development of nutrient recovery technologies was needed to make them more efficient and affordable, EPA developed the Challenge to harness the power of competition to tap into the ingenuity and creativity of innovators across the globe.

The Challenge is organized around four separate phases where innovators submit concept papers (Phase I), create designs from those concepts (Phase II), develop working prototypes/proof of concepts (Phase III), and finally, demonstrate pilots on livestock farms (Phase IV).

“The main goal of the Challenge is to raise awareness about the importance of this topic and to show that the EPA is being proactive in helping support the development of possible solutions,” said Fidan Karimova, water technology collaboration manager with the Water Environment & Reuse Foundation (WE&RF), who is involved with the competition as a planning committee member and a judge.

Importantly, the competition fulfills the need for regulators to be more closely involved with end users and the technology providers who want to bring their innovations to market - an approach that has proven successful in several European countries and could help build support for more effective solutions in the U.S., Karimova said.

“The biggest challenge is to design a technology that is scalable,” she said. “Many of these technologies are very promising but they are also early-stage and need piloting in order to eventually be proven in the market. The Challenge is a great platform to leverage the EPA’s assistance in this regard.”

Phase I winners

In Phase I of the Competition, which closed in January of this year, the EPA received a total of 75 concept papers from around the world and selected 34 of those submissions to advance to the next phase. The EPA also awarded a total of $30,000 in cash prizes to the top 10 entrants.

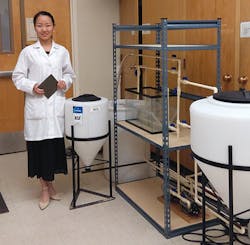

One of the Phase I concept winners includes an anaerobic digestion and solid-liquid separation technology for creating a dry biosolids fertilizer from manure. Developed by Bo Hu, Hongjian Lin, and Xin Zhang of the University of Minnesota, the AnSBEARs innovation utilizes digestion for generating energy and reducing sludge volume, and a two-step electrocoagulation phase for quick nutrient separation.

“Land application of manure is limited to sites close to the livestock due to the high transportation cost requirements,” said lead researcher Hu, an associate professor in the Department of Bioproducts and Biosystems Engineering. “With the increasing size of livestock farms, especially in areas where dairy farming is highly concentrated, tremendous amounts of surplus manure must be discharged while lands in the surrounding area become oversaturated with nutrients,” he said. “Soils with high levels of nitrogen and phosphorus have been linked to environmental problems in water bodies, such as eutrophication.”

Additionally, since swine manure contains phosphorus in a higher ratio, over-application of phosphorus is common when this manure is applied to crops for supplying nitrogen demand, Hu added.

By combining anaerobic digestion and electrocoagulation, Hu believes the AnSBEARs system can leverage both processes for better nutrient management and reducing the environmental footprint of the livestock industry. “We expect that the technology will produce nutrient-rich solids that farmers can transport more affordably or sell to other farmers when the market is appropriate,” Hu said.

Another Phase I winner includes an innovation from Israel-based Paulee Cleantec that uses a patent-protected exothermic oxidation process to quickly convert manure (and other feces) into an odor-free, organic fertilizer. The resulting non-toxic fertile ash can be applied to soil as a highly nutritious fertilizer, achieving nearly 100 percent nutrient recycling. The process can also handle manure immediately, eliminating the need for gallons of water to transfer the manure from one place to the other.

Given that the typical manure concentration in farm lagoons is less than 1 percent , as much as 100 gallons of freshwater are commonly needed to move less than one gallon of animal manure from the growing area to the lagoon, said Dr. IIan Levy, Paulee Cleantec chief executive officer. “We believe our technology offers a highly promising alternative to other manure management methods that are in practice today by proposing to avoid the need to mix in water, fundamentally changing the way we handle manure,” Levy said.

The EPA competition represents the right step forward in terms of developing a solution to the manure management problem by driving a collaborative environment between policy makers, farmers, technologists, and financiers, Levy noted.

“However, we need a lot more of a push in order to create a solution that is also affordable. To our understanding, the drive has to come from policymakers. The farmers can’t handle higher costs in technologies to manage manure. They are eagerly looking for solutions that are cost-effective as their profit margins are in constant decline.”

About the Author: Jeff Gunderson is a correspondent for Industrial WaterWorld. He is a professional writer with over 10 years of experience, specializing in areas connected to water, environment and building, including wastewater, stormwater, infrastructure, natural resources, and sustainable design. He holds a master’s degree in environmental science and engineering from the Colorado School of Mines and a bachelor’s degree in general science from the University of Oregon.