Hydrophilic Fiber Ball Filtration System for Oilfield Produced Water Treatment Applications

By Feiyu Ma

Produced water, which is a mixture of oil and water, is the largest waste stream generated in the oil and gas industry. To treat the produced water properly so it can be safely discharged or reused is a challenge many projects have to face.

There are many different technologies available for produced water treatment. One of the most commonly used technologies is a simple yet effective method: media filtration. There are many conventional filtration media available in the market such as anthracite coal or walnut shells. In addition, a new type of media, the Hydrophilic Fiber Ball Filtration System, is an ideal solution for produced water treatment.

Modified Fiber Material

In the treatment process, produced water flows through a chamber filled with fiber filtration media. The fiber filtration media come in two forms: fiber balls or fiber filter cartridges. The core technology of the system is fiber media that have been chemically modified with either oleophobic or oleophilic properties. Oleophobic means the fiber’s properties have been modified to repel oils, making it easy to backwash, while oleophilic means the fiber’s properties have been modified to attract oil. The fibers are capable of lowering the concentration of oil in produced water from levels as high as 1,000 ppm to below 1 ppm.

When in operation, the fiber ball filtration system feeds the produced water into a tank filled with oleophobic fiber balls about 40 mm in diameter (see Fig. 1). During the filtration process, the fiber balls are compressed by a vertical plunger from the top. When wastewater flows through the compressed fiber balls, oil droplets and suspended solids are removed at the precision level up to 2-5 μm. Oil droplets of smaller sizes may also be removed due to adsorption. Despite a high loading of suspended solids and oil, the media will not become fouled or blocked since the fibers are continuously repelling the oil. The fiber ball application is excellent for treating wastewater and produced water with high amounts of oil and suspended solids.

The filtration cartridge systems on the other hand provide a unique design by winding the oleophobic or oleophilic fibers adjacent to each another in tandem (see Fig. 2). The cartridges are installed inside pressurized filtration tanks. During operation, pressured produced water flows through the filter cartridges and small oil particles are attracted to the oleophilic fibers, colliding with each other to grow in size. This process is called coarse granulation. Once they become large enough, the particles are repelled by the adjacent oleophobic fibers. The droplets are at that point large enough to float to the surface on their own to be removed. The advantage of this application is that the wastewater is flowing through the media cartridge constantly so that the filter actually cleans itself during the filtration process. This unique feature provides an advantage that eliminates the need to backwash the filter cartridge and can extend the product life for many years before needing to be replaced.

This modified fiber technology has been used to successfully treat produced water in many different applications, both land-based and offshore, where oil and grease are the primary constituents of concern.

Case Study: Petroleum Processing Plant, Shanxi Province, China

The plant’s process capacity is 30 x 108 m3/a. It’s located on the Qinnan Basin in Shanxi. Its operations include collecting coalbed methane, dehydration, purification and pressure generation. The existing two 50 x 104 m3/d and two 150 x 104 m3/d turbochargers consume large amount of lubricants and discharge oil containing wastewater to the downstream treatment system.

Studies have shown that the Hydrophilic Fiber Ball Filtration is a high-efficiency and low-cost oil/water separation technology for highly emulsified oily wastewater treatment applications. It adopts a physical demulsification method and does not have any effect on the downstream waste oil recycling. As a result, it is widely used in the field of oil/water separation.

Oily wastewater in the treatment center is composed of two types, one of which is gas from each gas collecting station. When it passes through the compressor, some of the lubricating oil is entrained in the pipeline and mixed with the pipe cleaning water. The other type is the condensate generated by the increasing unit screw compressor in the factory. The two types of liquid are mixed to form the highly emulsified oil/water mixture, then it is mixed with fly ash to form a mixture of water, emulsified oil and fly ash mixture. Due to the complexity of the mixture, the factory’s existing sewage treatment process and equipment can’t meet the normal production requirements.

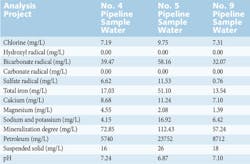

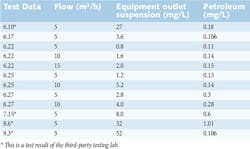

In the pilot test, samples of the oily sewage were taken and the analysis method of the corresponding national standards were used for the analysis of each project. Results are shown in Table 1.

From the analysis results, we can see that the sample of the pipeline cleaning water has low salinity, high iron content and a high level of oil content.

During the pilot testing, the fiber ball filtration system has processed a total of more than 20 barrels of waste oil since the date of operation, and collects about 2.5 tons of waste lubricating oil every month, with effluent water quality meeting the required standard. A water quality sample was sent to the local environmental monitoring station for monitoring. Test results from the monitoring report are shown in Table 2.

From the results, we can see that the petroleum level in the outlet is mostly under 1 mg/L. The suspension level in the treated water is also reduced and was able to meet the required discharge standard. The environmental challenge is overcome and at the same time the oil collected by media filtration can be recycled and reused.

About the Author: Feiyu Ma, P.E., M.S.Che.E., is the president of General Technologies and has over 17 years of experience in the water treatment industry.