Getting to Zero Liquid Discharge with Flue Gas Desulfurization Wastewater

By Krystal Perez, Thomas E. Higgins, Dennis Fink and Christina Joiner

Newly promulgated Steam Electric Power Effluent Limitation Guidelines (ELGs) for flue gas desulfurization (FGD) wastewater are based on biological treatment to remove selenium and nitrates. Consistently achieving ELGs with biological treatment can be challenging. Therefore, some utilities are considering zero liquid discharge (ZLD) options, such as mixing concentrated FGD wastewater with a solid that can be landfilled. Utilities may also be required to meet water-quality-based effluent limits (WQBELs) for sulfate or boron that can drive plants to ZLD. The key to making evaporative ZLD cost-competitive with physical/chemical plus biological treatment is reducing flow to the ZLD system, typically to less than 100 gallons per minute (gpm). In some circumstances, such as in the following case study, evaporation can be cost-competitive at higher flows.

Because each plant is unique, successfully achieving ZLD requires a careful analysis of flow reduction and optimization of the various evaporative technologies. This case study shares our experience and approach in successfully getting one plant to ZLD.

Overview

We worked with a confidential client to develop an approach to achieve ZLD of FGD wastewater and address future permit compliance, including a probable boron limit. The primary challenge was that installation of biological treatment for FGD wastewater would not achieve a boron water-quality-based limit. The only viable treatment option appeared to be eliminating the discharge altogether.

The plant’s FGD wastewater contained high concentrations of magnesium (~4,000 mg/L), sulfate (~14,000 mg/L), and nitrates (~80 mg/L as N), and low concentrations of chloride (~800 mg/L). Wastewater was blown down due to buildup of calcium sulfate and silica fine solids (~2 percent). Nitrate concentrations would have led to a larger biological treatment system, further leading to selection of ZLD for this case study plant.

We determined that wastewater disposal was driven by a fines buildup in the scrubber system. A solids removal process allowed recycle of treated water back to the scrubber, reducing flow to softening and evaporation from 650 to 250 gpm. This recycle approach lowered the overall capital cost of FGD treatment by approximately 23 percent and the annual O&M cost by approximately 18 percent compared to treating all FGD wastewater by evaporation.

Next, partial lime softening was implemented for magnesium, sulfate, fluoride, and boron removal, which reduced the likelihood of magnesium hydroxide (Mg(OH)2) scaling in the evaporator and reduced the salts fed to evaporator, reducing brine production. Finally, a disposable solid material was produced by mixing the brine with fly ash.

Together, reduced flow and partial lime softening lowered costs, making ZLD cost-competitive with biological treatment, and achieving future WQBEL limits for boron. Since the regulated utility cannot recover costs for future compliance, being cost-competitive with biological treatment allowed cost recovery for installing a ZLD system.

We used a chemistry and mass balance modeling tool to develop a ZLD approach to meet water-quality-based standards as well as ELGs. Laboratory-scale testing results were used to verify the computer model and simulate and assess the effectiveness of each treatment step.

Successfully Getting to Zero

The following are some important considerations for successfully achieving zero liquid discharge.

Understanding Key Drivers for FGD Wastewater Discharge - ZLD is typically more costly than other treatment technologies and ZLD costs are primarily driven by flow. Other technologies are primarily driven by mass of contaminants being removed plus flow. Therefore, the key to making ZLD cost-competitive is understanding the reasons for FGD wastewater blowdown. In our case study, the plant blew down due to a buildup of fine silica solids, which increased gypsum moisture and caused binding of their vacuum dewatering belts.

Since the FGD wastewater was discharged from the scrubber to purge solids, it was relatively low in dissolved salts. Other plants may blow down their scrubbers to purge chlorides based on the chloride limitations given the design metallurgy in their scrubbers and therefore may have higher concentrations of dissolved salts.

Reducing FGD Wastewater Flow - Next, methods for flow reduction should be evaluated. The high-total-suspended-solids (TSS), low-dissolved-salts FGD wastewater in our case study provided an opportunity to reduce the cost of ZLD, since treating for suspended solids removal is significantly less expensive than softening and evaporation.

We developed a design wherein a portion of the FGD wastewater flow would be treated for solids removal (see Fig. 1) and the treated water ultimately recycled back to the FGD system. The remaining FGD wastewater would be treated by lime softening, thermal evaporation, and the evaporator brine mixed with fly ash for disposal. This design concept reduced the FGD wastewater flow requiring softening and evaporation by 60 percent. Additional reduction in flow was limited by the metallurgy of the FGD systems as well as limited uses for recycle water when units were out of service.

This design concept was based on providing two evaporators, each sized for 60 percent of the maximum design flow. Additional equalization capacity was provided with the flexibility of processing extra flow through the solids treatment system and storing treated water in the recycle storage tank if an evaporator is down for maintenance. Stored water could be transferred from the recycle storage tank to the common equalization tank, where it could be treated through the ZLD system when the evaporator was back online.

Minimizing Evaporator Brine Volume - The FGD wastewater in our case study had high concentrations of magnesium, sulfate, and nitrates. Therefore, lime softening was implemented for magnesium and partial sulfate removal, leading to the reduced likelihood of magnesium hydroxide (Mg(OH)2) scaling. Pre-treatment softening for ZLD applications commonly considers full softening using both lime and soda ash. However, in this case study, using soda ash would not have reduced salts going to the evaporator, as doing so would have led to replacing the magnesium already removed with lime with the additional sodium from the soda ash, producing higher quantities of sludge primarily as calcium carbonate (CaCO3), and not removing sulfate. Lime-only softening showed an additional benefit of removing fluoride, thereby reducing fluoride carryover and limiting hydrofluoric acid formation farther downstream in the evaporator. Lime softening also reduced brine production, allowing beneficial reuse of more of the fly ash from the plant.

Depending on the composition of the FGD wastewater, other plants may see no significant benefit to softening and may instead consider brine concentrator technologies that do not typically require softening pre-treatment.

We paired the chemistry and mass balance model with an electrolyte chemistry simulation software, OLI Studio: Stream Analyzer (www.olisystems.com), to evaluate alternatives, size the evaporator, and estimate brine volume for ash mixing. Roughly 650 gpm of FGD wastewater was treated, generating 5 to 8 gpm of brine, or roughly a 100:1 concentration after recycling, softening, and evaporation were employed. Recycling accounts for over 60 percent of this concentration factor.

Brine Disposal - Fly ash and other materials can be mixed with concentrated brine, but additional solidification agents may be required to landfill FGD waste.

In our case study, evaporator brine would be mixed with fly ash such that roughly 200 tons per day of fly ash/FGD brine material would be generated when the plant is operating at maximum design flow. This assumes a 15 percent target moisture content in the wetted fly ash. Feasibility of ZLD can be limited by the production of fly ash that is available to mix with the brine. In our analysis, we considered the annual average coal use and then estimated 10 percent ash produced from coal and a typical mix of 80 percent fly ash and 20 percent bottom ash. Further, our analysis considered the fly ash that was currently used for offsite reuse and the associated cost penalty for using the fly ash for brine mixing that would be otherwise resold.

Laboratory Testing Proof of Concept

Laboratory testing was conducted to verify our chemistry/mass balance model and to evaluate the potential for metals cycling if landfill leachate is eventually treated in the new wastewater treatment system. The laboratory testing was conducted before the new treatment system was built, so testing included simulating the recycle of water after clarification, softening and evaporation, and landfill leaching of the fly ash/evaporator brine mixture.

The testing showed that approximately 62 percent of soluble boron was removed by softening, and as a result, boron cycling was not considered to be a problem in the FGD ZLD system. Soluble arsenic was shown to carry over to the fly ash/evaporator brine mixture but remained with the fly ash mixture and therefore did not contribute to increases of arsenic in the leachate compared to fly ash alone. The testing also showed that approximately 90 percent of selenium and 92 percent of mercury were removed, and the unremoved portions of these metals partitioned in the leachate.

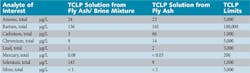

Further, toxicity characteristic leaching procedure (TCLP) testing of the fly ash/simulated brine mixture met TCLP limits for eight Resource Recovery and Conservation Act (RCRA) metals (see Table 1), and therefore the mixture would not be classified as a hazardous waste.

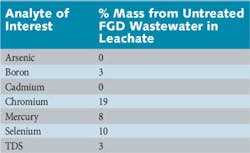

Our study determined that co-treatment of ash/brine leachate with FGD wastewater would likely be advantageous and evaluated whether parameters in the leachate from the fly ash/evaporator brine mixture could cycle up and impact performance of the FGD ZLD system. Boron was evaluated as a primary concern because it could cause operational problems to the evaporator as well as other metals and general chemistry parameters. Although adding evaporator brine to the fly ash prior to onsite landfilling would increase concentrations of most parameters, our test results and a system mass balance calculation indicated that the additional pollutant mass loading from the leachate was low in comparison to the untreated FGD wastewater (less than 10 percent of FGD wastewater mass loading for most parameters), and should not cycle up or significantly impact the FGD ZLD system performance (see Table 2). Chromium was the most recycled, but it is present in the wastewater at low concentrations and so is not a concern.

Author’s Note: Originally presented at the International Water Conference®: November 6-10, 2016. Please visit www.eswp.com/water for more information about the conference or how to purchase the paper or proceedings.

About the Authors: Krystal Perez, P.E., is Global Practice Lead for Industrial Water in Power Market; Thomas E. Higgins, Ph.D., P.E., is Industrial Water Power Market Senior Technology Fellow; Dennis Fink, P.E., is Senior Project Manager; and Christina Joiner is a Process Engineer, all with CH2M.