Nanobubbles for Enhanced Aeration

The Moleaer nanobubble aeration system is a patent-pending method of injecting oxygen into water so as to enhance the biological treatment process, reduce off-gassing and lower treatment costs. SoluOx is a highly efficient, proprietary, two-phase gasification process that saturates wastewater with dissolved oxygen and trillions of ultrafine nanobubbles that provide a latent transfer of oxygen for days after the point of aeration.

Due to their small size and high internal pressure, nanobubbles can remain stable in water for prolonged periods of time. Unlike microbubbles that rise and burst quickly on the surface, nanobubbles have minimal buoyancy and can disperse throughout a body of water due to the principals of Brownian motion. The longevity of the nanobubbles in the water, combined with a larger interfacial surface area, significantly increases their oxygen transfer capacity well beyond traditional aeration systems. Moleaer’s nanobubbles can be injected at any depth and oxygenate the entire column of water, including the bottom sludge layer that requires oxygen to support aerobic breakdown and conversion of nutrients.

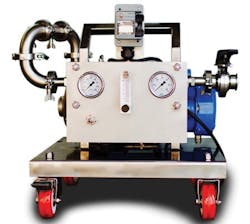

As opposed to traditional aeration, which relies on large HP blowers with diffusers or surface aerators to transfer oxygen into wastewater, SoluOx generators can be installed in-line utilizing existing pumps to inject nanobubbles into passing water, or they can operate with their own dedicated pumps. In-line use means existing aeration systems can increase oxygen delivery without additional energy consumption. In addition, SoluOx generators create a low-turbulence, oxygen-rich environment enabling aerobic bacteria to function more efficiently.

Installation is quick, with minimal retrofitting, meaning there is no disruption to daily operations. The system has a proven track record of reliability and is rated for 10+ years of continuous operations. Ideal for industrial wastewater treatment, food/beverage, cooling towers and applications in the pulp & paper industry, the units are self-cleaning and do not foul or plug like traditional diffusers. They are mounted on the outside of a tank or on the bank of a lagoon, thus giving operators easy access and control of the unit. The generators can alternate between air and high-purity oxygen depending on the given oxygen demand of the treatment system, and they can also be turned on and off to conserve energy when required.

Moleaer is a technology company that specializes in developing innovative high-tech solutions for a wide variety of industrial and environmental applications. For more information, visit www.moleaer.com.