Using Quench Glands

BY Robert L. Matthews

Often overlooked, quench glands are installed on many ANSI pumps and aren’t being used to perform their intended functions. Quench glands direct the pump packing leakage to a U-drain or away from the floor surrounding the pump when piped to do so. This keeps the pump floor area dryer and cleaner, eliminating any wet, slimy and slippery spots by the pump.

Quench-type packing glands do a great job in effluent, chemical, pulp, water and other applications and they have many uses like a 6-in-1 tool.

Most plant maintenance personnel are familiar with mechanical seal quench options but how many know about quench and drain for packing? I ask this question because I see a lot of quench glands on pumps in the field that aren’t used or at least not to their fullest. When I ask why, most maintenance and operations personnel tell me they don’t know that it’s a multi-functional gland. With a water connection, this gland can capture the liquid that leaks past the packing and divert it to a drain or containment source. Crystals or other deposits that build up around the packing gland and shaft area can be captured and removed by steam mist or quench water. The quench water can also cool the shaft to reduce heat from being transferred to the bearings or seal air ingestion from pumps that experience vacuum on occasions.

Quench glands also can help address housekeeping issues, such as reducing area clean-up time; but more important are safety issues that can be resolved by containing substances like caustics and other irritants. How many times have we seen a green slime build up on the concrete from packing-related water flowing on the floor and thought of how slick the wetted area becomes?

Quench glands can be used to divert packing leaks to a drain or to another area, but not a stuffing box leak from stuffing box bore wear (note the leaking gland water not at the shaft but at the OD of the gland pictured). Although this is called a packing leak it’s not caused by the packing; most packing can only expand and seal by design a certain amount, but that’s another topic in understanding how packing works. We must be careful, as we attempt to troubleshoot, to understand components to the fullest.

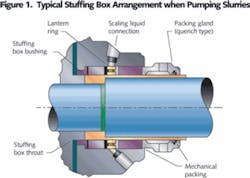

The gland shown in Figure 1 is a quench-type gland. Water, oil or other fluids can be injected into it to remove heat from the shaft, thus limiting heat transfer to the bearing frame. This permits pump operating temperatures to be higher than limits of the bearing and lubricant design. The same quench gland can be used to prevent escape of a toxic or volatile liquid around the pump. In this case, it’s called a smothering gland, with external liquid simply flushing away the undesirable leakage to a sewer or waste receiver.

Today, though, stringent emission standards limit use of packing to non-hazardous water-based liquids. This, plus a desire to reduce maintenance costs, has increased preference for mechanical seals. Pump manufacturing representatives can explain and help with gland options to improve many pumping applications.

I’ve seen hundreds of quench glands installed to compress and adjust the pump packing, but they can do so much more. Several years ago, I had the pleasure of discussing the options of this quench gland with pump design engineer Walt Connolly at Gould’s Pumps and determined it’s possibly one of the most misunderstood pump components in use today.

About the Author: Reliability manager for Houston-based Royal Purple Ltd., Bob Matthews has 35-plus years of pump industry experience - from hands-on to supervision - in plant maintenance management, consulting and training. He has taught advanced pump rebuilding, lubrication, mechanical seals, braided packing, operator awareness, and other customized classes for companies like Exxon, Phillips, Westinghouse as well as Auburn, University of Alaska, LSU, the Vibration Institute, ASME and FSA.