Lube Job — ISO oil cleanliness is next to godliness.

by Robert L. Matthews

Lubricants are a critical reliability component. Their quality largely determines how efficiently, how long, and how reliably equipment will run.

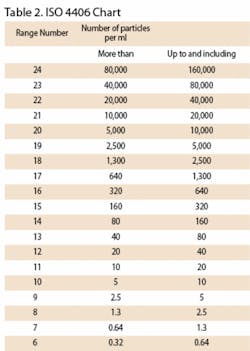

Clean oil equals longer equipment life, and clean oil is achieved by effective filtration, clean containers, and proper fluid handling by maintenance personnel. Now, this isn't news to most of the industry but the ISO Cleanliness Code is an eye opener. The numbers for the code increase by one as they go up the scale, but the number of particles double at each step.

An ISO Code will usually have three numbers, e.g., 18/16/14. The first number is particles = (equal to or greater than) 2 microns (µm), the second number is = 5 µm , and the third number is = 15 microns.

The difference is so big and especially when you look at what manufacturers recommend for equipment sold to end-users. Look at the difference between a 14 at the low end with 80 particles and 18 at the high end at 2,500 particles, Wow, 4 points more can equal 2,420 more particles. I made this example to the extreme and you bet your hydraulic system is impacted by the 30X more particles.

The primary function of a lubricant is to separate and reduce the friction between two moving surfaces. How close are the lubricated surfaces:

- Rolling element bearings have clearances 0.1-to-1.0 µm.

- Journal bearings have clearances 0.1-to-100 µm.

- Servo spool valves have clearances 0.1-to-4.0 µm.

- Gears have clearances 0.1-to-1.0 µm.

- Gear pump teeth have clearances 0.5-to-1.0 µm.

The look at typical clearances like these make the number and size of = 2 µm particles become evident. Clean the system, use clean lubricant, and have an educated millwright put the lubricant in. Start with this and in the next steps add the upgrade seals, breathers, sight indicators, check temperatures, vibration analysis, and ultrasound. Also look at the new MLT1 certifications (Maintenance Lubrication Technician Level 1), good luck growing with these enlightening times.

About the Author: Reliability manager for Houston-based Royal Purple Ltd., Bob Matthews has 35+ years of pump industry experience – from hands-on to supervision, in-plant maintenance management, consulting and training. He has taught advanced pump classes for Fortune 500 companies, universities, the Vibration Institute, ASME and FSA. Contact: www.royal-purple.net