Direct Technology Comparisons Tricky in Brine Management

By Paul O’Callaghan and Michael Mickley

The common denominator in the suite of emerging brine management technologies is salt. Beyond that, the commonalities fade away. There is a mixture of physical, physical-chemical and chemical-based technologies, each at different stages of development and each with a different fundamental underlying mechanism of operation.

BlueTech Research, a market intelligence specialist, is currently visiting this topic as part of its upcoming Brine Management Insight Report, identifying the unmet needs and attempting benchmark technologies in an uneven playing field.

Brine may include desalination concentrate, produced and flowback water, mine drainage water and industrial wastewater. Nearly all brines require disposal and, driven by regulatory pressures, treatment of brine is increasingly necessary to facilitate disposal and reclaim more product water.

While there is not a mainstream market today in brine management, there is perhaps an inevitable market. The drivers include increasing concerns regarding increased salinity in areas such as the Persian Gulf, environmental concerns about impacts on coastal ecology and limited disposal options for industry and in inland areas.

Figure 1 depicts the conventional and most frequently used processing sequence for high-recovery of both lower salinity and higher salinity feedwater. This sequence hits both CAPEX and OPEX, with energy costs contributing most to the OPEX. For lower salinity feedwater, the costs of the reverse osmosis (RO) step predominate, and for higher salinity feedwater the thermal evaporation costs predominate.

In the past decade, efforts to improve costs include alternative technologies and modification of existing ones. The primary marketing opportunities driving this development are in the oil and gas industry for treatment of waters from both conventional and unconventional sources.

Prime areas of interest are Zero Liquid Discharge (ZLD) and Minimum Liquid Discharge. ZLD has been the domain of companies such as GE, Aquatech, Veolia and Siemens. The dominant technologies have been brine evaporators and crystallizers.

A new crop of technologies is emerging based on approaches including forward osmosis, membrane distillation, liquid-liquid phase ion extraction, electro-separation and variations around humidification and dehumidification.

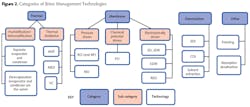

BlueTech’s research shows that most efforts have targeted alternatives to the conventional brine concentrator. Many of the efforts have reached the stage of pilot testing, and a few companies have commercial products. Figure 2 lists brine management technologies, including several existing technologies such as multistage flash (MSF) and multi-effect distillation (MED), which are being modified.

The focus on lower-cost energy sources has led to many efforts highlighting the possible use of solar, geothermal and, in particular, waste heat including low-grade heat. Cost reduction has also focused on improving heat transfer and system recovery, for example from reduction in energy requirements and reducing performance limitations due to scaling and fouling.

The challenge with a benchmarking exercise for brine management such as BlueTech’s is that each of the technologies may have a slightly different operating envelope, in terms of the inlet and outlet, and also in terms of what they can tolerate and how much pretreatment is required.

Newer applications including those in the oil and gas industry frequently involve more complex waters than in other applications. This has resulted in the need for both improved pretreatment processes and more robust desalination processes.

The industrial players, including oil and gas companies, power companies, anyone with cooling tower blow-down or boiler water concentrate, are keeping a lookout for solutions that help provide cost-effective disposal options, while the larger water technology industry players should be watching very closely as the range of different technologies start to prove themselves in demonstration-scale applications.

About the Authors: Paul O’Callaghan is CEO of BlueTech Research, a consultancy that provides water technology market expertise and strategic advice on technology development and commercialization to start-up firms, the investment community and larger water corporations. Michael Mickley is an internationally recognized expert in concentrate and brine management and member of the O2 Environmental Technology Assessment Group.