Market Outlook: Market Trends in Brine Treatment and Zero Liquid Discharge

By James Fotouhi

In a recently completed report looking at technology trends in the $100-million per-annum zero liquid discharge (ZLD) market, BlueTech Research has observed that while over 500 ZLD systems have been installed since the 1980s, the growth in new projects has remained relatively modest, with an estimated 10 to 20 new systems built each year.

The issue of brine disposal is a growing challenge for both the municipal and industrial sectors, partly due to the proliferation and cost competiveness of desalination systems. Whether in the Kenya Coal Seam Gas produced water treatment plant in Queensland or brackish water desalination systems in Texas, brine represents a major cost center for operators.

A survey by the International Desalination Association in 2012 indicated that over 98 percent of inland desalination facilities in the United States dispose of waste brine through deep well injection, evaporation storage or municipal sewage discharge, as opposed to some form of treatment.

Brine disposal costs show considerable variability. In the oil and gas sector, for instance, the typical disposal method, deep well injection, costs operators $3 to $6 million. In formations with challenging geology and long transportation pathways, this cost can be much higher. In the Marcellus region, disposal costs range as high as $20 million because produced water has to be transported hundreds of miles offsite.

Despite these high costs, the primary incentive for going ZLD remains regulation. Instead of seeing growth in areas such as brine treatment for brackish water or tight oil/gas produced-water treatment, growth in ZLD and brine treatment systems in recent years has been seen in coal-to-liquids plants in Inner Mongolia and chemical plants in India, where sensitive downstream environments have led to the regulation of industrial discharges.

Innovations in Process Design

Novel systems for treating high salinity brines have been developed, such as forward osmosis membranes and electro-separation systems. However, the majority of companies developing brine treatment systems focus on process changes to thermal desalination systems, trying to address the high capital and energy costs of conventional brine concentrators and crystallizers.

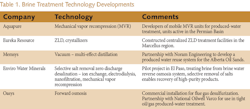

There is a high barrier to entry in the ZLD/brine treatment market, given that the majority of projects are in the industrial sector and that variability in feedwater quality presents operational challenges. Notable brine treatment companies currently being tracked by BlueTech Research are listed in Table 1.

About the Author: James Fotouhi is a technology market research analyst with BlueTech Research, a consultancy that provides water technology market expertise and strategic advice on technology development and commercialization to start-up firms, the investment community and larger water corporations.