How Advanced Self-Cleaning Technology is Unlocking Value in Food & Beverage Wastewater Treatment Applications

By Ben Orton

Water is becoming an increasingly costly resource due to tightening regulations on wastewater effluent limits and water scarcity issues caused by population growth, droughts, pollution, and competition.

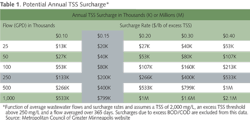

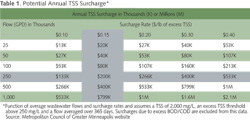

Increases are coming in the form of: a higher cost of fresh water and municipal wastewater treatment1 -- up to an 8-percent increase in water costs in major cities; the growing cost of pretreating water in-house to comply with lower effluent limits prior to discharge; and escalating fines and surcharges imposed on companies that exceed thresholds for total suspended solids (TSS) and biological oxygen demand (BOD). At current growth rates, these costs are becoming larger threats to future profitability. Surcharges, a growing phenomenon, are increasing an average of 5.6 percent per year, or two times the consumer price index (see Table 1).

Companies wishing to sustain profitable growth increasingly need wastewater treatment solutions that are affordable, reliable, low-maintenance, and hassle-free to ensure compliance with changing regulations and requirements.

Special Challenges: Food & Beverage

Food and beverage (F&B) companies are particularly challenged, as they often produce large volumes of wastewater high in TSS, BOD, and fats, oils and greases (FOG). There may also be a high degree of variability in these wastewaters, depending on what processors are running through the plant and down the drain. While some companies have the capability to fully treat wastewater to a level that can be discharged into the environment, many send their wastewater to municipal treatment plants. Companies in the latter category are looking to add or expand "in-house" pretreatment of wastewater to lower TSS, BOD and FOG, and to control pH.

This allows F&B processors to do the following:

- More consistently and reliably stay below TSS limits to avoid fines and compliance issues as well as surcharges imposed by municipalities. This not only saves money but also gives management breathing room to focus on more important revenue-generating activities.

- Potentially reuse water in areas that do not pose a public health risk, which can notably reduce freshwater bills paid to utilities.

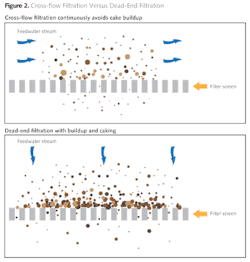

Traditionally, TSS reduction is accomplished through coarse screening and clarification methods, such as settling or dissolved air flotation (DAF). Filtration of finer particles down to 10 microns, however, has been challenging and impractical in plants that only pre-treat wastewater due to the high solids loadings and FOG, which quickly clog traditional dead-end filters like bags and cartridges. This, in turn, requires frequent backwash cycles or screen replacement, leading to higher maintenance, downtime, consumables costs, and waste disposal. New technologies, however, are providing alternatives.

Turning Heads: An Emerging Opportunity

Advances in self-cleaning, cross-flow filtration technology are starting to turn heads in the industry, as companies discover that they can reduce TSS in a more operationally efficient manner. The TEQUATIC™ PLUS Filter, for example, is designed to continuously operate in very high and highly variable solids wastewater (in excess of 10,000 mg/L of TSS) without the need for backwashing, chemical cleaning or frequent filter changes. The build-up of particles is avoided due to the unique, continuous brushing action of a proprietary cleaning assembly, thus creating a condition where particles prefer to flow past the screen rather than through it (see Fig. 1).

Advanced self-cleaning filters can provide a relatively low cost and simple option for solids reduction in wastewater prior to discharge. As shown in Figure 2, there are opportunities to deliver value at several points in the wastewater treatment process.

Achieving Goals: Performance Success

Advanced self-cleaning filters are proving their value in installations and pilots in several F&B applications. For example, a large brewery in California discovered that it could use advanced self-cleaning filtration technology to save more than $500,000 per year in TSS surcharges by removing the majority of solids in digester effluent prior to it leaving the plant. A successful pilot demonstrated the ability for an advanced self-cleaning filter to reduce TSS by 60 to 80 percent from 800 mg/L, saving the brewer $300 in surcharges per pound of solids removed. Capturing solids may also bring added value as animal feed or feedstocks to produce energy.

In another F&B industry application, a pork processing plant in Oklahoma demonstrated that it can save $180,000 per year in chemical costs by filtering solids prior to a DAF. Physically separating out 50 percent of the solids entering the DAF from an initial level of 1,750 mg/L lowers the requirement for coagulants and polymers. Overall, a 60-percent reduction in chemical costs could be realized. In the future, this plant hopes to completely replace the DAF with the self-cleaning filter.

Similarly, a beef processing plant in Texas sees the potential to save $250,000 per year on its water utility bill by reusing DAF effluent in the spray bars that clean the drum screens at the front of the wastewater treatment train. To protect the spray bars from clogging, the plant turned to an advanced self-cleaning filter technology. In a recent pilot, the filter continuously operated in high FOG/DAF effluent with TSS in the hundreds, successfully removing particles greater than 30 microns.

Lastly, a pork processing plant in Kansas notably reduced costs and improved the capacity of its wastewater reuse system with advanced self-cleaning filtration technology. The plant is utilizing the self-cleaning filter after a DAF to protect bag filters in addition to an ultrafiltration (UF) filter. Without the self-cleaning filter, high FOG and TSS drove the plant to change out bag filters every 5 minutes during the nighttime wash-down period.

The UF filter was losing 80 percent of its capacity due to fouling, requiring chemicals to recover the capacity. Advanced self-cleaning filters were installed after a successful pilot, in which TSS was reduced by 60 percent from the DAF effluent with water recovery greater than 99 percent. More than 98 percent of particles larger than 20 microns were removed. During the pilot, the UF capacity was maintained and bag filter changeouts were 80-percent less frequent.

Looking Ahead and Beyond

These success stories indicate the promising potential for advanced self-cleaning filters to solve important challenges in industrial wastewater treatment plants. Filters capable of operating continuously in high TSS waters with challenging constituents like FOG offer a relatively simple and perhaps lower cost solution for TSS reduction than what is presently found using chemicals, settling and flotation. With TSS levels often in the thousands of mg/L, and high levels of FOG and fibrous material, F&B companies are prime candidates to benefit from advanced self-cleaning filters.

The challenges faced by this industry, however, are not unique. The same opportunities to save on chemical costs, utility bills and surcharges exist across industrial markets, and advanced self-cleaning filters are proving their worth there as well, including agricultural waste, plastics recycling and upstream oilfield applications.

If the challenges of constrained water supplies and more stringent environmental regulations persist, which many believe they will, companies should expect water to become an increasingly costly resource. Companies that want to find more efficient, lower-cost methods to treat wastewater and keep it from impacting their profitability would be wise to consider the use of advanced self-cleaning filters.

About the Author: Ben Orton is the marketing manager for filtration at Dow Water & Process Solutions. He is responsible for creating strategic marketing and product strategies for UF products and the TEQUATIC PLUS Filter within North America, developing new markets and driving next-generation technologies in collaboration with key customers. He can be reached by email at [email protected] or by phone at 952-897-4313.

References:

1. National Association of Clean Water Agencies, Wastewater Service Charge Index 2013, May 2014, http://www.nacwa.org/images/stories/public/2014-05-08indexfinal.pdf.